Home > Manufacturing & Processing Machinery > Metallic Processing Machinery > Metal Drawing Machinery > New Condition Wire Mesh Deck Shelving Automatic Production Line Automatic Metal Wire Welding Machine

New Condition Wire Mesh Deck Shelving Automatic Production Line Automatic Metal Wire Welding Machine

US$ 0.4 - 150000

MOQ: 1 Set

Key Specifications

Get Latest Price

Business Type:

Manufacturer

Year Established:

2006

Annual Export Value:

US$1 Million - US$1.5 Million

Payment & Shipping

Payment Methods:

Port of Shipment:

Shanghai

Delivery Detail:

20 days

New Condition Wire Mesh Deck Shelving Automatic Production Line Automatic Metal Wire welding Machine

Voltage

380V

Style

Vertical

Warranty

1 Year

Key Selling Points

Easy to Operate

After-Sales Service Provided

Engineers Available to Service Machinery Overseas

Machine Type

Wire Mesh Welding Machine

Usage

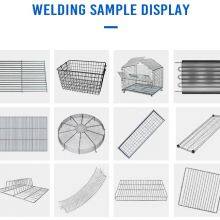

Welding Ofall Kinds of Wire Mesh

Supply Ability

20 Set/Sets Per Quarter

Power Cable

120mm²,400A

Machinery Test Report

Provided

Effective Welding Width

1200mm

Effective Welding Length

3000mm

Automatic Moving Speed

200-500mm/S Adjustable

Transport Package

Wooden Seaworth Package

Specification

500KG

Trademark

TS

Origin

China

Production Capacity

According to Product

Product Description