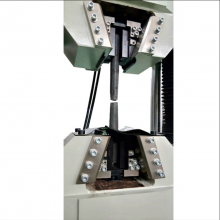

1000kN Hydraulic Universal Pull Test Equipment Usage Tear Strength Tester WAW-1000B

1. Main functions and features of testing machine

1) Using microcomputer controlled high precision electro-hydraulic servo valve to drive precise hydraulic cylinder and can realize constant speed control to test force, displacement, deformation, etc. and so that to make tensile, compression, bending tests. If equipped with accessories, it can comply with other test requirements for various materials;

2) Adopting underneath type hydraulic cylinder, which is installed at the bottom of the main machine, running stably; upper and lower jaw base are open structure, easy to clamp specimen;

3) Independent hydraulic servo loading system, using high precision broadband electro-hydraulic servo valve to ensure system high precision, high efficiency, low noise, quick response; using independent hydraulic clamping system to ensure system run stably and low noise, and no-slipping of specimen during test.

Computer control and processing system:

l Servo control system: complete test parameters setting, test procedure auto control, data acquisition, processing, analysis, storage and display (test data including: upper and lower yield points, tensile strength, break strength, elastic modulus, elongation, proof strength of non-proportional elongation, etc.). It can realize closed-loop control of test force, deformation, displacement and constant speed control to test force, strain, displacement, deformation;

l Displaying test force, peak, deformation, piston displacement, test curve on screen, with intelligent system of full keyboard input and control mode, which can realize arbitrary setting and smooth shift between control modes;

l Complete data acquisition and processing (with many test methods, standards). With functions of simulation and reproduction of test procedure, re-analysis of test data, enlargement, comparison, traverse, zoom in or out of test curves;

l Using modularization, open programming, human design, users can freely adjust test standards, test reports, test parameters to meet with their different requirements, easy to upgrade and manage rights;

l Using database to manage test data;

l With expansion and updating capacity.

4) protection functions:

l limit position protection for oil cylinder;

l over current protection for hydraulic system;

l overload protection;

l over current, over voltage protection;

l safe protection at the time of specimen break;

l automatic protection after test.

2. Specifications of testing machine

No. | Item | Spec. | |||

1 | Model | WAW-300 | WAW-600 | WAW-1000 | WAW-2000 |

1 | Max. load | 300KN | 600KN | 1000KN | 2000KN |

2 | Relative error of test force | ≤±1% | ≤±1% | ≤±1% | ≤±1% |

3 | Measuring range of load | 6-300KN | 12-600KN | 20-1000KN | 40-2000KN |

4 | Relative error of deformation measuring | ≤±0.5% | ≤±0.5% | ≤±0.5% | ≤±0.5% |

5 | Stroke of piston | 250mm | 250mm | 250mm | 250mm |

6 | Relative error of displacement measuring | ≤±0.5% | ≤±0.5% | ≤±0.5% | ≤±0.5% |

7 | Constant displacement control range | 0.5-50mm/min | 0.5-50mm/min | 0.5-50mm/min | 0.5-50mm/min |

8 | Max. Speed of crossbeam | 200mm/min | 200mm/min | 200mm/min | 200mm/min |

9 | Max. Speed of piston | 70mm/min | 70mm/min | 70mm/min | 70mm/min |

10 | Tensile space | 650mm | 700mm | 700mm | 900mm |

11 | Compression space | 500mm | 600mm | 650mm | 800mm |

12 | Clamps for round specimen | Φ6-Φ26mm | Φ13-Φ40mm | Φ13-Φ60mm | Φ26-Φ70mm |

13 | Width of flat specimen | 70mm | 82mm | 82mm | 82mm |

14 | Thickness of flat specimen | 0-15mm | 0-40mm | 0-40mm | 0-40mm |

15 | upper and lower compression platens | 160mmX160mm | 160mmX160mm | 160mmX160mm | 240mmX240mm |

16 | Extensometer | Gauge length:50mm Deformation:10mm | Gauge length:50mm Deformation:10mm | Gauge length:50mm Deformation:10mm | Gauge length:50mm Deformation:10mm |

17 | Voltage | 3 phase 4 wire, 380V, 50Hz | 3 phase 4 wire, 380V, 50Hz | 3 phase 4 wire, 380V, 50Hz | 3 phase 4 wire, 380V, 50Hz |

18 | Dimension of main machine | 750X600X2000mm | 800X600X2400mm | 950X700X2550mm | 1300X800X3300mm |

19 | Dimension of control cabinet | 1100X700X940mm | 1100X700X940mm | 1100X700X940mm | 1100X700X940mm |

20 | Structure | 2 columns 2 screws | 4 columns 2 screws | 4 columns 2 screws | 4 columns 2 screws |

21 | Clamping mode | hydraulic clamping/manually | hydraulic clamping/manually | hydraulic clamping | hydraulic clamping |

Send Inquiry to This Supplier

You May Also Like

-

1000kn Metal Materials Electro-hydraulic Servo Universal Tensile Testing Machine Steel Tube Tensile Testing MachineUS$ 7000 - 30000MOQ: 1 Set

-

WAW-1000B Bending Test Using Utm Universal Testing Machine With OEM Factory PriceUS$ 7000 - 30000MOQ: 1 Set

-

UTM / TTM / Tensile Testing Machine / Lab Test Equipment 600kN (WAW-600B)US$ 7000 - 30000MOQ: 1 Set

-

WAW-600B 600kN Compressive Strength and Elastic Modulus Testing Machine for Rock Core SpecimensUS$ 7000 - 30000MOQ: 1 Set

-

UTM Hydraulic Universal Testing Machine Used Concrete Specimen Poisson Ratio TesterUS$ 7000 - 30000MOQ: 1 Set

-

600kN Hydraulic Universal Testing Machine Peel Strength Testing Machine WAW-600BUS$ 7000 - 30000MOQ: 1 Set

-

Auto Test Equipment for Tensile Compression Strength TestUS$ 7000 - 30000MOQ: 1 Set

-

China Manufacturer Supply WAW-600B 600kN Electro-hydraulic Universal TesterUS$ 7000 - 30000MOQ: 1 Set

-

600kN WAW-600B 60 Ton Universal Testing Machine / Tensile Testing Machine for Steel Bar RebarUS$ 7000 - 30000MOQ: 1 Set

-

600kN Material Testing Machine Usage Servo-hydraulic Testing Machines WAW-600BUS$ 7000 - 30000MOQ: 1 Set