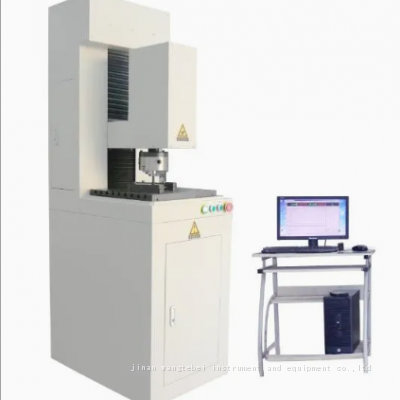

Vertical Torsion Testing for Metal and Wire Torsion Test for Shafts and Rods

Features

Adopting precision servo motor drive to ensure constant torsional speed;

Precision reducer transmission ensures high efficiency and stability of transmission, with smoother transmission, lower noise, more accurate positioning, and better repeatability of test results;

Adopting high-precision screw rods for higher stability;

Professional high-performance control system, fully automatic measurement;

The electrical control system has high stability, smooth and reliable operation, and fast response;

Simple and easy to operate, the highly simplified control system places all the tedious settings in the background for one click start;

Computer control, supporting Windows and Office software, combined with an optimized comprehensive data processing system, with strong data and graphic processing functions, can instantly print complete test reports and torsion torsion angle test curves. Open structure, user-friendly human-machine interface operation, curve drawing mode, and clearer testing process.

Equipped with comprehensive overload protection, emergency stop and other safety protection functions.

Diversified functions, with various control methods such as torque load and axial load automatic control, automatic maintenance, and self programming control, can achieve one machine with multiple functions and multiple uses.

Standard

1. JB/T9370-2015 Technical Conditions for Torsion Testing Machines

2. GB2611-2007 General Technical Requirements for Testing Machines

3. JJG269-2006 Verification Regulations for Torsion Testing Machines

Specifications

| 1 | Style: Vertical |

| 2 | Range: ± 50N. m |

| 3 | Torque measurement range: 1% -100% FS |

| 4 | Minimum torque reading value: 0.001Nm |

| 5 | Relative error of torque indication: ± 0.5% |

| 6 | Relative error of torque repeatability: 0.5% |

| 7 | Corner measurement range: unlimited |

| 8 | Direction of torque increase: in both positive and negative directions |

| 9 | Minimum reading value for corner: 0.01 ° |

| 10 | Test speed: 0.1-720 °/min |

| 11 | Relative error of torsional speed indication: ± 0.5% |

| 12 | Distance between two clamps: 0-300mm |

| 13 | Power supply: AC 220V ± 10%, 50Hz; |

Send Inquiry to This Supplier

You May Also Like

-

Torsion Testing Equipment for Lab Torsion Test Machine for Automotive Parts Torsion Testing Machine for UniversitiesUS$ 8000 - 13000MOQ: 1 Set

-

ISO 7802 Metallic Wire Wrapping Test Machine Testing EquipmentUS$ 3000 - 5000MOQ: 1 Set

-

ISO 7802 Wire Wrapping Tester for Metal Wires FactoryUS$ 3000 - 5000MOQ: 1 Set

-

Wire Wrapping Test Machine for Metallic Materials PriceUS$ 3000 - 5000MOQ: 1 Set

-

Metal Wire Wrapping Strength Testing Machine SupplierUS$ 3000 - 5000MOQ: 1 Set

-

ISO 7802 Metallic Wire Wrapping Bending Tester ManufacturerUS$ 3000 - 5000MOQ: 1 Set

-

Metallic Wire Wrapping Performance Test EquipmentUS$ 3000 - 5000MOQ: 1 Set

-

ISO 7802 Wire Bending Wrapping Test ApparatusUS$ 3000 - 5000MOQ: 1 Set

-

Metallic Wire Wrapping Fatigue Testing MachineUS$ 3000 - 5000MOQ: 1 Set

-

ISO 7802 Compliance Wire Wrapping TesterUS$ 3000 - 5000MOQ: 1 Set