Commercial Lithium Battery Recycling Machine for Australia Green Tech Solution for Battery Waste

Waste lithium battery recycling machine is used to process various waste lithium-ion batteries, separate copper, aluminum, graphite powder and lithium cobalt oxide powder, and achieve efficient recovery of valuable metals. DOING lithium battery recycling equipment includes key components such as crushing system, pyrolysis system, multi-component screening system, stripping and sorting system and environmental protection treatment system.

Lithium battery recycling machine

Raw materials:

The batteries that can be processed by lithium battery recycling machine include: cylindrical lithium batteries, ternary lithium batteries, automotive lithium batteries, lithium iron phosphate batteries, power lithium batteries, steel shell lithium batteries, mobile phone lithium batteries, etc. The processing capacity can reach 500-3000kg per hour.

Raw materials

Lithium battery recycling machine working process:

Step 1: Soak the waste lithium battery in sodium chloride solution to short-circuit the positive and negative poles of the battery, thereby releasing excess battery energy.

Step 2: Send the discharged lithium battery to the shredder and crusher for processing into small particles.

Step 3: Carbonization. Organic matter is converted into carbon-like substances by heating battery residues in a low-oxygen environment. This process can remove the diaphragm of lithium batteries. If you need to collect the diaphragm of lithium batteries, DOING can also equip you with linear screening to select the diaphragm of lithium batteries according to your needs.

Step 4: Use drum screening to select black powder. Most manufacturers on the market are equipped with linear screens, which not only have a small output, but also have unclean screening. DOING is equipped with a drum screen with a sorting rate of up to 90%.

Step 5: The crushed fragments of lithium batteries enter the magnetic separator, and the iron is separated by magnetic attraction. The remaining materials are turned into powder by the mill and then enter the separation machine such as circular vibration screen, airflow specific gravity separator, etc., which use the difference in material size and weight to efficiently separate copper, aluminum and black substances.

Lithium battery recycling machine

The above is the entire workflow of lithium battery recycling machine. In addition, our lithium battery recycling machine is also equipped with a gas purification system, which can not only filter out most of the dust contained in the exhaust gas, but also make a variety of mixed exhaust gases meet the emission standards.

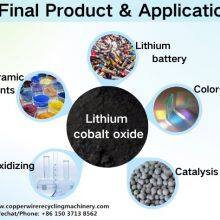

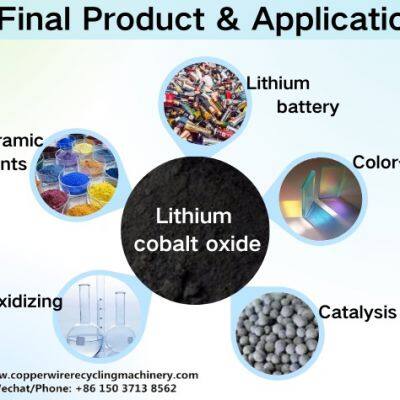

Products and applications:

Products and applications

DOING lithium battery recycling machine adopts dry mechanical crushing and physical sorting technology, which can efficiently recycle valuable parts of lithium-ion batteries, such as black powder, diaphragm, copper and aluminum. The separated copper and aluminum can be sold directly to the metal trading market for profit. The black substances are mainly graphite powder and lithium cobalt oxide, both of which have a wide range of uses. Taking graphite powder as an example, graphite powder can be used in environmental protection and energy saving, industrial product manufacturing and other aspects, and its utilization value is very high.

Advantages of lithium battery recycling machine:

1. Environmental protection: This process uses physical methods for recycling, without the use of chemical reagents, so it will not pollute the environment.

2. High efficiency: The lithium battery recycling machine operates under negative pressure, without dust leakage, and the separation efficiency can reach more than 99%. The machine can effectively remove impurities such as diaphragms, electrolytes, binders, etc., which improves the recycling efficiency and recycling quality.

3. Economic: It adopts PLC control system and is easy to operate. It saves electricity, manpower and is highly efficient. The recycling cost of this process is low, which can effectively improve the economic benefits of the enterprise.

As a professional lithium battery recycling machine manufacturer, DOING is committed to providing customers with feasible solutions and professional support. If you want to know more about the price, recycling volume and other information of DOING lithium battery recycling machine, please follow and contact us.

Send Inquiry to This Supplier

You May Also Like

-

Henan Doing Gourp Lithium Battery Recycling Machine For SaleUS$ 70000 - 350000MOQ: 1 Set

-

Low Cost High Profit Lithium Battery Recycling Machine EV Battery Recycling Machine for SaleUS$ 70000 - 350000MOQ: 1 Set

-

500-3000kg/h Hot Sale Henan Doing Electric Car EV Battery Recycling Line Cell Phone Lithium Ion Cell Recycling MachineUS$ 70000 - 350000MOQ: 1 Set

-

Waste Lithium Li Lon Battery Recycling Machine 500 KG/H Cell Electric Car Battery Lithium Lon Battery Recycling PlantUS$ 70000 - 350000MOQ: 1 Set

-

500 KG/H Lithium Lon Battery Recycling Machine Electric Car Battery Recycling PlantUS$ 70000 - 350000MOQ: 1 Set

-

Large Scale Lithium Battery Crushing And Separation MachineUS$ 70000 - 350000MOQ: 1 Set

-

Lithium Ion Battery Recycling Machine For Black Mass And MetalUS$ 70000 - 350000MOQ: 1 Set

-

Cylindrical Lithium Battery Recycling MachineUS$ 70000 - 350000MOQ: 1 Set

-

Factory Delivery Lithium Battery Recycling MachineUS$ 70000 - 350000MOQ: 1 Set

-

Lithium Ion Battery Recycling Plant Cost in IndiaUS$ 70000 - 350000MOQ: 1 Set