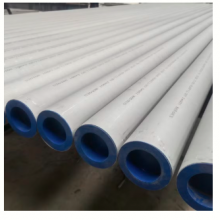

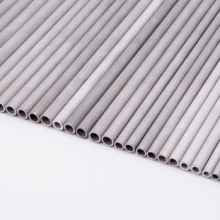

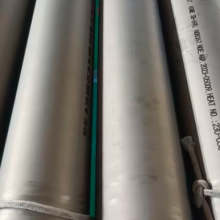

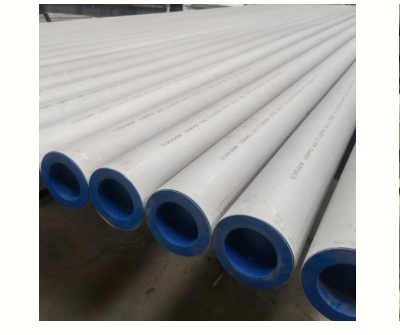

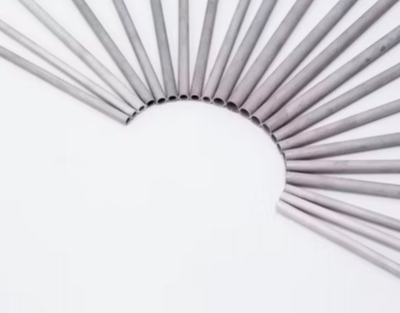

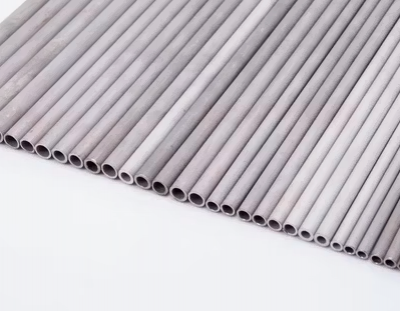

ASTM Round/Square/Rectangular Ss 201 304/304L 316/316L 310S 309S 409 904 430 Brushed/Welded Stainless Steel Tube Pipe Price

Company Profile

Zhongzheng Stainless Steel Co., Ltd. was established in 2018 with aregistered capital of 20 million yuan. lt is a manufacturing company thatintegrates the production of special materials, manufacturing andprocessing, sales, and technology development. The company covers anarea of 2,000 square meters and has 200 employees. it has built worldclass stainless steel seamless pipe (hot piercing, cold drawing, cold rollingproduction lines, precision steel pipe production lines, and large, mediumand small-sized welded pipe production lines. The company has beencommitted to providing high performance, high precision, hightemperature-resistant, high pressure-resistant, and corrosion-resistantsolutions and technical services for industrial equipment pipeline systems.The company specializes in producing a series of steel pipes, pipe fittingsflanges, etc., such as high-temperature (nickel-based) alloys, austeniticduplex steel, urea grade stainless steel, super stainless steel, etc. Thecompany is equipped with an annual production capacity of 5,000 tons ofstainless steel seamless pipe production line, 7,000 tons of welded pipeproduction line, and 500 tons of pipe fittings production line, etc. lt canoroduce stainless steel seamless pipes with diameters ranging from Φ6 toΦ762 and wall thicknesses ranging from 0.5 to 70 mm, stainless steelwelded pipes with diameters ranging from Φ15 to Φ2200 and wallthicknesses ranging from 0.5 to 80 mm, pipe fittings, and various stainlesssteel ingots, round steel, rough pipes, etc., according to customerrequirements and in accordance with standards such as GB, ASTM, etc.

| Material | Stainless Steel Seamless Pipe |

| Steel Grade | 200 Series: 201,202 300 Series: 301,304,304L,304H,316,316L,316Ti,317L,321,309s,310s 400 Series: 403,405,409L,410,416,420,431, 434 Duplex Steel: 904L,2205,2507,2101,2520,2304 |

| Thickness | 0.1mm-100mm (as required) |

| Length | 6m,9m,12m (as required) |

| Surface | Pickling,Polished,Bright,Hairline |

| Technique | Cold Rolled, Hot Rolled |

| Treatment | Welded or Seamless |

| Welding Line Type | ERW,EFW,Seamless,Spiral Welded |

| Shape | Round,Square,Rectangular,Oval |

| Color | Golden/Rose Gold/Silver/Black/Red/Green/Blue/as required |

| Tolerance | As standard |

| Delivery Time | 7-10days |

| Payment Terms | T/T, L/C, D/P, Paypal, Trade Online |

| MOQ | 0.5 Ton |

| Application | Liquid transport, Boiler pipe, Hydraulic,Automobile,Mining, Construstion |

Nominal | Outside Diameter | Sch 5S | Sch 10S | Sch-40S | Sch-80S | Sch-160S | Sch-XXS | |||||||

mm | inch | mm | WT mm | Weight (Kg/mt) | WT mm | Weight (Kg/mt) | WT mm | Weight (Kg/mt) | WT mm | Weight (Kg/mt) | WT mm | Weight (Kg/mt) | WT mm | Weight (Kg/mt) |

3 | 1/8 | 10.3 | 1.24 | 0.276 | 1.24 | 0.28 | 1.73 | 0.37 | 2.41 | 0.47 | - | - | - | - |

6 | 1/4 | 13.7 | 1.24 | 0.390 | 1.65 | 0.49 | 2.24 | 0.631 | 3.02 | 0.80 | - | - | - | - |

10 | 3/8 | 17.1 | 1.24 | 0.490 | 1.65 | 0.63 | 2.31 | 0.845 | 3.20 | 1.10 | - | - | - | - |

15 | 1/2 | 21.3 | 1.65 | 0.800 | 2.11 | 1.00 | 2.77 | 1.27 | 3.75 | 1.62 | 4.75 | 1.94 | 7.47 | 2.55 |

20 | 3/4 | 26.7 | 1.65 | 1.03 | 2.11 | 1.28 | 2.87 | 1.68 | 3.91 | 2.20 | 5.54 | 2.89 | 7.82 | 3.63 |

25 | 1 | 33.4 | 1.65 | 1.30 | 2.77 | 2.09 | 3.38 | 2.50 | 4.55 | 3.24 | 6.35 | 4.24 | 9.09 | 5.45 |

32 | 1 1/4 | 42.2 | 1.65 | 1.65 | 2.77 | 2.70 | 3.56 | 3.38 | 4.85 | 4.47 | 6.35 | 5.61 | 9.70 | 7.77 |

40 | 1 1/2 | 48.3 | 1.65 | 1.91 | 2.77 | 3.11 | 3.68 | 4.05 | 5.08 | 5.41 | 7.14 | 7.25 | 10.16 | 9.54 |

50 | 2 | 60.3 | 1.65 | 2.40 | 2.77 | 3.93 | 3.91 | 5.44 | 5.54 | 7.48 | 8.74 | 11.1 | 11.07 | 13.44 |

65 | 2 1/2 | 73.0 | 2.11 | 3.69 | 3.05 | 5.26 | 5.16 | 8.63 | 7.01 | 11.4 | 9.53 | 14.9 | 14.2 | 20.39 |

80 | 3 | 88.9 | 2.11 | 4.51 | 3.05 | 6.45 | 5.49 | 11.30 | 7.62 | 15.2 | 11.1 | 21.3 | 15.24 | 27.65 |

100 | 4 | 114.3 | 2.11 | 5.84 | 3.05 | 8.36 | 6.02 | 16.07 | 8.56 | 22.3 | 13.49 | 33.54 | 17.12 | 41.03 |

125 | 5 | 141.3 | 2.77 | 9.47 | 3.40 | 11.57 | 6.55 | 21.8 | 9.53 | 31.97 | 15.88 | 49.11 | 19.05 | 57.43 |

150 | 6 | 168.3 | 2.77 | 11.32 | 3.40 | 13.84 | 7.11 | 28.3 | 10.97 | 42.7 | 18.2 | 67.56 | 21.95 | 79.22 |

200 | 8 | 219.1 | 2.77 | 14.79 | 3.76 | 19.96 | 8.18 | 42.6 | 12.7 | 64.6 | 23.0 | 111.2 | 22.23 | 107.8 |

250 | 10 | 273.1 | 3.40 | 22.63 | 4.19 | 27.78 | 9.27 | 60.5 | 12.7 | 96.0 | 28.6 | 172.4 | 25.40 | 155.15 |

300 | 12 | 323.9 | 3.96 | 31.25 | 4.57 | 36.00 | 9.52 | 73.88 | 12.7 | 132.0 | 33.32 | 238.76 | 25.40 | 186.97 |

350 | 14 | 355.6 | 3.96 | 34.36 | 4.78 | 41.3 | 11.13 | 94.59 | 19.05 | 158.08 | 35.71 | 281.70 | - | - |

400 | 16 | 406.4 | 4.19 | 41.56 | 4.78 | 47.29 | 12.7 | 123.30 | 21.41 | 203.33 | 40.46 | 365.11 | - | - |

450 | 18 | 457.2 | 4.19 | 46.80 | 4.78 | 53.42 | 14.27 | 155.80 | 23.8 | 254.36 | 45.71 | 466.40 | - | - |

500 | 20 | 508.0 | 4.78 | 59.25 | 5.54 | 68.71 | 15.09 | 183.42 | 26.19 | 311.2 | 49.99 | 564.68 | - | - |

600 | 24 | 609.6 | 5.54 | 82.47 | 6.35 | 94.45 | 17.48 | 255.41 | 30.96 | 442.08 | 59.54 | 808.22 | - | - |

PMC has always inculcated and followed sten quality standards for all of its manufacturing processes. All the materials used by PMC are of premium quality and compatible with latest machineries and manufacturing technologies. The technical and commercial quality guidelines of PMC are set to high standards. A quality control team supervises quality assurance and control aspects along with the entire process system by recognizing and associating with the quality circle. The quality control tests are conducted regularly in order to maintain a consistent and uniform product quality.

| Destructive Testing | |||||

| • | Tensile Test | • | Flaring Test | • | IGC Test - Prac A,B,C&E |

| • | Hardness Test | • | Flange Test | • | Reverse Flattening Test |

| • | Flattening Test | • | Reverse Test - Bend Test | • | Impact Test |

| Non- Destructive Testing | |||||

| • | Hydrostatic Test | • | P.M.I Test | • | Dye Penetrant Test |

| • | Eddy Current Test | • | Spectro Test | • | Baroscopic Test |

| • | Air Under Water Test | • | Ultrasonic Test |

VALUE-ADD SERVICES BY PMC

| Stainless steel pipe polish | Stainless can polish nearly any stainless steel pipe item to a #4 polish, #6 Polish, #7 polish or a #8 mirror finish. Stainless steel polished pipes can also be cut to size. |

| Stainless Steel Pipe Beveling | Stainless can bevel the edges of stainless steel plate to prepare for welding or other processes. |

| Stainless Steel Pipe Honing & Turning | Stainless can hone pipe and tube, using a precision abrasion process in order to obtain a desired finish or close dimensional tolerance. |

| Heatreating & Annealed | Some grades of stainless steel pipe can be heatreated to change the mechanical properties. |

| Positive Material Identification (PMI) | Stainless can perform PMI testing in house for most stainless steel grades, or we can work with independent labs to complete PMI in order to meet customer specifications. |

| UT Testing | In some cases, UT testing of the stainless steel plates may be required. We can assist you with this requirement. |

FAQ

Q1. What are your company's main products ?

A2: Our main products are stainless steel seamless pipe, welded pipe, fittings(flange,elbow, tee, reducer,nipple etc.), and sheets, pipes, coils, strips, bars and channels.

Q2. What are the advantages of your company ?

A2: Offering finest quality-best in class products-at the most advantageous rates, as our forte.

Q3. How do you control quality ?

A3: A quality control team supervises quality assurance and control aspects along with the entire process system by recognizing and associating with the quality circle. The quality control tests are conducted regularly in order to maintain a consistent and uniform product quality.

Q4. How many coutries you already exported ?

A4: Exported to more than 50 countries mainly from Middle East, Russia, United States, Canada, Italy, Germany, Australia, Egypt, Japan, Indonesia, Bangladesh, Turkey, India, etc.

Q5. Can you provide sample ? Do you support OEM ?

A5: Yes. Small samples in store can be provided for free. Customized samples will take about 2-3days.

Q6: What's your payment terms ?

A6: By T/T(30% deposit in advance, balance 70% before shipment),, L/C after sight 30~120 days. Western Union, Paypal, or Trade Online.

Call to Action (CTA)

📞 Contact Now for Best Price!

📧 Email: jane@zjzzgy.cn

💬 WhatsApp: +86 19005872308

Send Inquiry to This Supplier

You May Also Like

-

ASTM Ss A312 304 304L 310 310S 316 316L 321 347 904L S31803 S32205 S32750 Smls Weld Seamless Welded Stainless Steel TubingUS$ 2.1MOQ: 300 Kilograms

-

Good Quality Stainless Steel Welded 201 304 316 Grade Stainless Steel Tube/PipeUS$ 800 - 1100MOQ: 1 Ton

-

ASTM A249/A269 304/304L 316/316L/316ti 321 Welded Stainless Steel Heat Exchanger Tube, Condenser Tubing, Boiler PipeUS$ 800 - 1100MOQ: 1 Ton

-

Factory Price ASTM AISI Welded Seamless Alloy/Precision ERW/Black/Oiled/Round/Square 201 304 316 316L 409 436 439 Stainless Steel Tube/PipeUS$ 750MOQ: 3 Tons

-

Whenzhou China Factory Nickel Alloys 108mm Diameter API 5L Gr. B Seamless Stainless Steel/Carbon Steel Welded Nuclear Power PipeUS$ 2.0MOQ: 500 Kilograms

-

Customized DN100 ASTM A213 T91 Alloy Steel Boiler PipeUS$ 800 - 1100MOQ: 1 Ton

-

ASTM AISI A312 Corrision Resistant Stainless Steel Welded Pipe Inox Tube DN8mm-DN2000mm 304 304L 316L 316ti 317L 724L 725ln S38815 S32615NegotiableMOQ: 1 Piece

-

Austenitic Stainless Steel Industrial Grade Seamless Pipe 304 321 316 2205 310S ASTM A240/A213 1.4845, GB/T14976-2012US$ 800 - 1100MOQ: 1 Ton

-

AISI SUS Ss 201/202/304/304L/316/316L/310S/410/420/430/904L/2205/2507 Stainless Steel Welded Seamless Tube PipeUS$ 1500MOQ: 49 Tons

-

Wholesale Price Polish ISO Standard Welded Seamless Round Stainless Steel Pipe ASTM 301 304 310 316 321 Pipe for DecorationUS$ 2000MOQ: 1 Ton