MOOG Servo Valves in Steel Mills: Enhancing Precision and Efficiency

In the demanding environment of steel mills, where precision, efficiency, and reliability are paramount, MOOG Servo Valves have emerged as a critical component in the automation and control systems. These high-performance valves, renowned for their exceptional accuracy and responsiveness, play a pivotal role in enhancing the productivity and operational safety of steel production processes. This article delves into the application of MOOG Servo Valves in steel mills, highlighting their key features, benefits, and specific use cases.

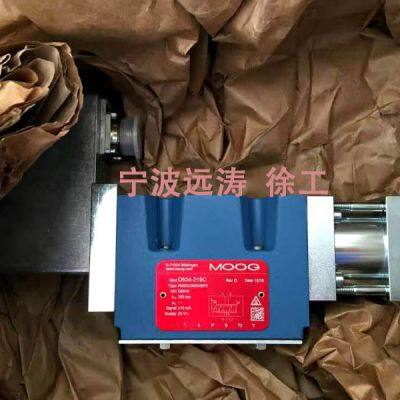

1. Introduction to MOOG Servo Valves

MOOG, a global leader in motion and fluid control systems, offers a comprehensive range of Servo Valves designed to meet the rigorous demands of industrial applications. These valves are engineered to convert electrical signals into precise hydraulic control actions, enabling accurate positioning, speed, and force control. In steel mills, where precise control of hydraulic systems is crucial for various processes, MOOG Valves provide an ideal solution.

Precision Control: MOOG Valves are known for their high precision and repeatability, ensuring accurate control of hydraulic systems even under demanding conditions.

Fast Response Time: These valves have a rapid response time, allowing for quick adjustments and precise control of hydraulic actuators. This is particularly important in processes that require rapid changes in pressure or flow.

Durability and Reliability: MOOG Valves are built to withstand harsh industrial environments, featuring robust construction and materials that resist wear and tear. This ensures long-term reliability and reduces maintenance costs.

2. Key Features of MOOG Servo Valves in Steel Mills

In steel mills, MOOG Servo Valves come with several key features that enhance their performance and usability. Here are some of the notable features:

High Flow Capacity: MOOG Valves offer high flow capacity, making them suitable for controlling large hydraulic systems commonly found in steel mills. This ensures efficient operation and reduces the need for multiple valves.

Advanced Feedback Mechanisms: These valves incorporate advanced feedback mechanisms, such as position feedback and load feedback, enabling precise control and monitoring of hydraulic systems. This helps in maintaining optimal performance and preventing system failures.

Rugged Construction: MOOG Valves are designed to withstand the harsh conditions of steel mills, including high temperatures, dust, and vibration. They feature rugged housings, corrosion-resistant materials, and high-temperature ratings, ensuring long-term reliability.

Versatile Mounting Options: These valves offer versatile mounting options, allowing for easy integration into existing hydraulic systems. This reduces installation time and costs, and ensures compatibility with a wide range of hydraulic components.

Enhanced Diagnostics: MOOG Servo Valves come with enhanced diagnostic capabilities, enabling quick troubleshooting and maintenance. This helps in minimizing downtime and ensuring smooth operation of the steel mill.

3. Applications of MOOG Servo Valves in Steel Mills

MOOG Servo Valves find extensive application in steel mills, where they are used to control various hydraulic systems involved in the production process. Here are some of the key applications:

Rolling Mills: In rolling mills, MOOG Valves are used to control the hydraulic systems that power the rolls. They ensure precise control of roll gap, speed, and force, enabling the production of high-quality steel products with consistent dimensions and surface finish.

Continuous Casting: In continuous casting processes, these valves are used to control the hydraulic systems that regulate the flow of molten steel into molds. They ensure precise control of the casting speed and the level of molten steel in the mold, preventing defects and ensuring consistent product quality.

Hydraulic Presses: In hydraulic presses used for forging and stamping steel products, MOOG Servo Valves provide precise control of pressure and force. This ensures accurate shaping of steel products and reduces the risk of defects or damage.

Automation Systems: MOOG Valves are also used in the automation systems of steel mills, where they control various hydraulic actuators involved in material handling, transportation, and storage. They enable precise positioning and movement of heavy loads, ensuring safe and efficient operation.

Cooling Systems: In cooling systems used to regulate the temperature of steel products during processing, MOOG Valves control the flow of coolant. They ensure precise temperature control, preventing overheating or undercooling of steel products and ensuring consistent product quality.

4. Case Studies: MOOG Servo Valves in Action

To illustrate the effectiveness of MOOG Servo Valves in steel mills, here are a few case studies:

Case Study 1: Rolling Mill Automation: A leading steel mill implemented MOOG Valves in its rolling mill automation system to improve product quality and productivity. The valves provided precise control of roll gap, speed, and force, enabling the production of high-quality steel sheets with consistent thickness and surface finish. As a result, the mill experienced a significant increase in productivity and a reduction in defects.

Case Study 2: Continuous Casting Control: Another steel mill used MOOG Valves to control the flow of molten steel in its continuous casting process. The valves ensured precise control of the casting speed and the level of molten steel in the mold, preventing defects such as porosity and segregation. This led to improved product quality and reduced waste.

MOOG Servo Valves play a critical role in enhancing the precision, efficiency, and reliability of steel production processes. Their key features, such as high flow capacity, advanced feedback mechanisms, and rugged construction, make them ideal for the demanding environment of steel mills.

Send Inquiry to This Supplier

You May Also Like

-

Siemens MotorsNegotiableMOQ: 1 Unit

-

Schneider Variable Speed DrivesNegotiableMOQ: 1 Unit

-

Schneider Soft StartersNegotiableMOQ: 1 Unit

-

Schneider Circuit BreakersNegotiableMOQ: 1 Unit

-

Schneider ContactorsNegotiableMOQ: 1 Unit

-

ABB Gas Chromatograph AnalyzersNegotiableMOQ: 1 Unit

-

ABB Laser Gas AnalyzersNegotiableMOQ: 1 Unit

-

Siemens Gas AnalyzersNegotiableMOQ: 1 Unit

-

Rexroth PumpsNegotiableMOQ: 1 Unit

-

Rexroth ValvesNegotiableMOQ: 1 Unit