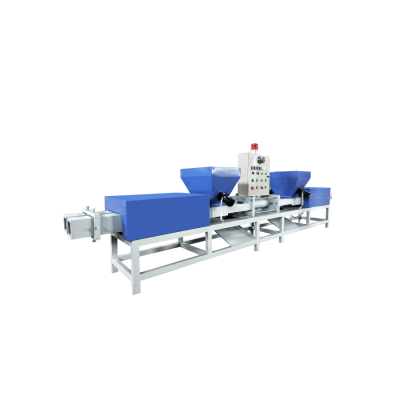

Hot Selling Four Column Pallet Block Making Machine for Sale

Products Description

Pallet block machine is a core equipment designed for wooden pallet manufacturing, used to produce pallet support components (footpiers).

Diversified raw materials

Raw materials consist of two major categories: wood-based and non-wood materials. Wood materials include virgin timber (hardwoods like oak/maple, softwoods like pine/cedar, eucalyptus), wood processing residues (sawdust, wood powder, bark), and fast-growing plantation timber (poplar, paulownia). Non-wood materials involve bamboo resources (fiber, bamboo powder), agricultural waste (wheat/rice straw, coconut husk, bagasse), industrial byproducts (rice husk, palm empty fruit bunches), and other plant fibers (sisal, banana stems). Utilizing eco-friendly compression molding technology, these renewable resources achieve effective recycling while meeting diverse load-bearing requirements.

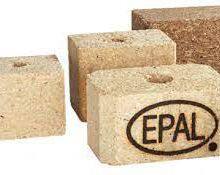

High strength and stability: wood chips, wood shavings and glue (urea-formaldehyde glue or MDI glue) are used for hot pressing under high temperature and high pressure. It has strong load-bearing capacity, and it has been tested that it will not crack after being soaked in water for 48 hours, and it can adapt to harsh environments.

Environmental protection and energy saving: Wood waste is used as the main raw material, which is in line with the concept of sustainable development. At the same time, the efficient design of the dryer and hot pressing process (such as airflow drying technology) during the production process reduces energy consumption.

Precise size and customization: It supports standard specifications such as 90×90mm and 100×100mm, and can customize special shapes and sizes according to needs. The automatic cutting machine ensures cutting accuracy and smooth and flat cut surfaces.

Excellent processing performance: Strong nailing force, suitable for scenes such as fumigation-free wooden pallet brackets, and the finished product is clean and free of debris, which improves the efficiency of subsequent processing.

Efficient and flexible production: The fully automated production line (such as double-export/triple-export molding machine, automatic cutting) supports 4-8m³/24h production capacity, low labor demand (2-3 people), and can adapt to production needs of different scales.

FAQ

What is a pallet blockmachine?

The pallet block machine is an automated production equipment used to quickly make the supporting pallet blocks at the bottom of wooden pallets. It produces standard-sized pallet pallet blocks by pressing and shaping wood scraps or recycled wood, replacing traditional manual cutting, improving efficiency and reducing costs.

Is the equipment complicated to operate? Is professional training required?

The equipment uses an automated control system with a simple and intuitive operation interface. We provide free operation training to ensure that users master the basic operations, and come with detailed instructions and after-sales technical support.

What are the raw materials for producing pallet blocks?

Supports a variety of raw materials: wood scraps, sawdust, recycled wood, and even some straw fibers.

Can the size and load-bearing capacity of the pallet block be customized?

Supports customized molds to produce pallet blocks of different heights and shapes

Does the equipment consume a lot of energy?

The standard model has a power of 16 kW, and the comprehensive energy consumption cost is reduced by about 40%.

Send Inquiry to This Supplier

You May Also Like

-

Industrial-Grade Reinforced Heavy Duty Wooden Pallets for Shipping and Storage FacilitiesUS$ 40000MOQ: 1 Set

-

Turnkey High-Capacity Complete Wooden Pallet Production Line for Large-Scale Manufacturing PlantsUS$ 40000MOQ: 1 Set

-

Smart Energy-Efficient Wood Pallet Fully Automatic Machine for Streamlined Factory OperationsUS$ 40000MOQ: 1 Set

-

Eco-Friendly High-Density Compressed Wooden Pallets for Sustainable Biomass Fuel ManufacturingUS$ 40000MOQ: 1 Set

-

Modular High-Speed Machinery for Making Wood Pallets in Custom Packaging SolutionsUS$ 40000MOQ: 1 Set

-

Lightweight Cost-Effective Packaging Pressed Wood Pallets for Export and Retail DistributionUS$ 40000MOQ: 1 Set

-

Competitive Low-Cost Wood Pallet Price Solutions for Bulk Purchasing and Supply Chain OptimizationUS$ 40000MOQ: 1 Set

-

High-Strength Compressed Sawdust Pallets for Global Export and Eco-Friendly Logistics NetworksUS$ 40000MOQ: 1 Set

-

Fully Automated Wood Pallet Recycling Machine for High-Volume Waste Management FacilitiesUS$ 40000MOQ: 1 Set

-

Premium Automatic Pallet Press 55KW Motor 180mm s Fast ProductionNegotiableMOQ: 1 Set