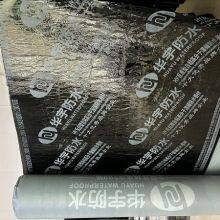

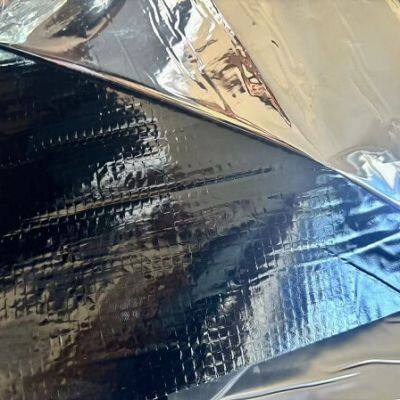

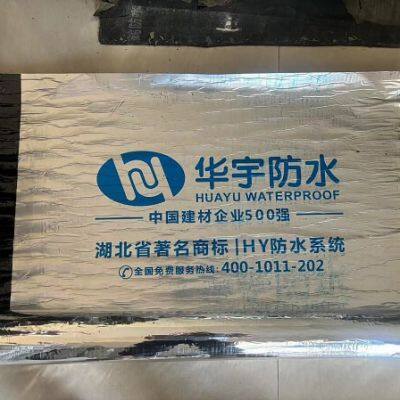

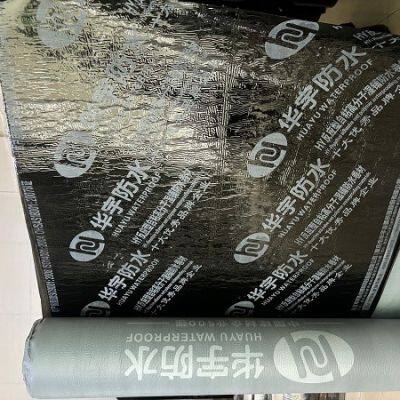

Self Adhesive Polymer Modified Bitumen Waterproof Membrane

Product Features

1、Tackifying resin enhances the membrane's adhesion strength, ensuring a secure bond with the substrate.

2、Strong initial adhesion allows for secure bonding at temperatures above 5°C without the need for heating equipment, it is safety, environmental friendliness, and convenience.

3、The polyester mat (PY) reinforcement layer provides puncture resistance, abrasion resistance, and tearing resistance, increasing the material's strength and effectively protecting against damage and destruction from both the upper and lower 4、Excellent self-healing properties for fine cracks caused by external stresses.

5、 Durable adhesion ensures that the membrane does not detach or leak at the bonding points, with the lap joints having the same lifespan as the membrane itself.

6、High elongation (elongation rate ≥ 30%), with strong adaptability to substrate shrinkage, deformation, and cracking.

7、Does not flow at high temperatures and does not crack at low temperatures, offering a wide range of temperature for use (high temperature: 70°C, low temperature: -20°C).

How to Use :

Hot Adhesive Construction:

Construction Process - Subgrade treatment → Additional layer construction → Hot adhesive large area construction (laying the membrane) → Air expulsion and compaction → Water tightness test → Protective layer construction

Key Points of Construction -

1、Subgrade treatment: Clean the surface first; the subgrade should be solid, smooth, and clean.

2、Additional layer construction: For areas such as corners, pipe roots, gutters, and expansion joints, additional layer treatment should be applied by pre-cutting the membrane to the appropriate size and shape.

3、Large area construction: Use non-curing adhesive for hot adhesive waterproofing membrane composite construction, ensuring the non-curing coating thickness meets relevant specification requirements; roll out the waterproofing membrane while applying the non-curing adhesive.

4、Lap joint treatment: The lap width of the membrane should be 100mm; the lap area should be sealed separately, using the hot adhesive method. The lap joint should be filled with an Bitumen strip.

5、Water tightness test: Conduct the water tightness test according to the construction plan requirements.

6、Protective layer construction: A protective layer should be set up on the outer surface of the waterproof layer according to relevant specifications or design requirements.

Send Inquiry to This Supplier

You May Also Like

-

Self Adhesive Polyurethane Aluminum 2Rs-A/180 Enameled Wire EnameledNegotiableMOQ: 1 Kilogram

-

Low Cost Self Adhesive High Visibility Reflective Tape Sticker for TruckNegotiableMOQ: 1

-

20ml Loctiter Super Glue Type 401 402 403 Repairing Glue Instant Adhesive Self-AdhesiveNegotiableMOQ: 1

-

0.3mm 2UEW Bonding Self-adhesive Enameled Copper Magnet Wire for Speaker Voice CoilUS$ 9.90 - 10.00MOQ: 1000 Kilograms

-

High Quality Heavy Duty Non Adhesive Self Fusing Silicone Grip Sports Shovel Handle TapeUS$ 3.60 - 9.80MOQ: 2 Rolls

-

Digital UV Flatbed Printer Self Adhesive Plastic Label Printing/ Four Color Advertising Printing Machine/printing Machine for stNegotiableMOQ: 1

-

Self Adhesive Membrane TapeUS$ 0.34 - 6MOQ: 500 Rolls

-

Treble Self Adhesive HooksUS$ 0.7 - 1MOQ: 1000 Pieces

-

Self-adhesive Seal StripNegotiableMOQ: 1 Meter

-

Fiberglass Self-Adhesive TapeNegotiableMOQ: 1000 Rolls