Polyvinyl Chloride PVC Powder Coating Dip Powder for Wire Mesh Fence, Dip Electrostatic Spray Grade

Polyvinyl Chloride PVC Powder Coating Dip Powder is a type of thermoplastic powder coating formulated to be suitable for fuidized bed dipping process. lt is made by Polyvinyl Chloride (PVC) resin as base material and adding plasticizers, pigments and other additives.

Features of PVC powder coating

• Advantages: It has excellent weather resistance, outstanding corrosion resistance, high mechanical strength, good electrical insulation, and is relatively low in price, offering high cost-effectiveness.

• Disadvantages: The difference between the melting temperature and decomposition temperature of polyvinyl chloride resin is small, and strict temperature control is required during the coating process; otherwise, it is prone to decomposition. Harmful gases will be emitted during the impregnation process. The surface of the coating is not smooth enough, making it difficult to apply a thick coating. Moreover, the adhesion of the PVC coating is poor. For products with high adhesion requirements, special primers need to be used.

Application field

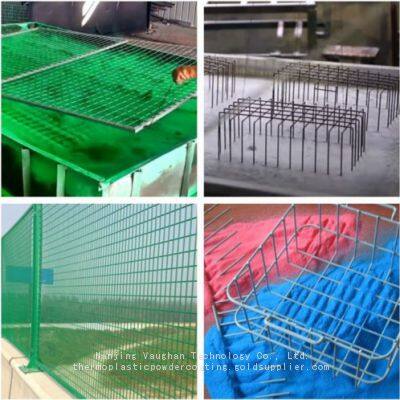

• Construction industry: It is used for surface coating of building components such as doors and Windows, curtain walls, and guardrails, such as fences for parks, courtyards, gardens, roads, and residences.

• Industrial field: It is suitable for welded wire mesh, steel wire, steel pipe, perforated mesh, etc., and can also be used in hardware craft frames, shopping mall shelves, clothes hangers, bicycle baskets, breeding cages, highway guardrails, etc.

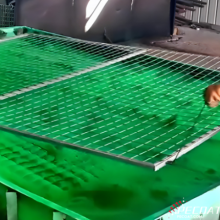

Coating process

The fluidized bed impregnation process is generally adopted. The specific steps are as follows: First, the workpiece is pre-treated, and rust and oil are removed through phosphating or sandblasting, etc. Then apply a special water-based primer to enhance adhesion; Then preheat the workpiece to 250-300℃ (adjust according to the thickness of the workpiece metal); Immerse again in the fluidized bed for 4 to 20 seconds (adjust according to the thickness and shape of the metal); Then, post-heating curing is carried out at a temperature of 230-250℃ for 0-5 minutes. Finally, let it cool naturally or by air.

PVC powder coating, short for Polyvinyl Chloride powder coating, has emerged as a versatile and innovative solution in the world of surface finishing. This unique coating material offers a wide array of benefits that make it a popular choice across various industries.

One of the most notable advantages of PVC powder coating is its exceptional durability. Once applied and cured, it forms a tough and resilient layer that can withstand significant wear and tear. This makes it ideal for use in high - traffic areas and on products that are exposed to harsh environmental conditions. Whether it's industrial equipment, outdoor furniture, or automotive parts, PVC powder coating provides long - lasting protection against scratches, abrasions, and corrosion.

Packing : 25kg/bags

Another key benefit is its excellent chemical resistance. PVC is highly resistant to a wide range of chemicals, including acids, alkalis, and solvents. This property makes it suitable for applications where the coated surface may come into contact with potentially damaging substances. For example, in the chemical industry, PVC powder - coated pipes and storage tanks can safely handle corrosive chemicals without deteriorating over time.

The aesthetic appeal of PVC powder coating is also a major selling point. It comes in a vast range of colors and finishes, allowing for endless customization possibilities. From sleek and shiny to matte and textured, manufacturers can achieve the desired look to enhance the visual appeal of their products. This makes PVC powder coating a popular choice for consumer goods, such as electronics, appliances, and furniture, where appearance plays a crucial role in attracting customers.

In addition to its durability, chemical resistance, and aesthetic appeal, PVC powder coating is also environmentally friendly. Unlike traditional liquid coatings, which often contain volatile organic compounds (VOCs) that can harm the environment and human health, PVC powder coating is a dry - powder formulation that produces zero VOC emissions during application. This makes it a more sustainable option for companies looking to reduce their environmental impact. Furthermore, PVC powder coating is relatively easy to apply. It can be applied using various methods, such as electrostatic spraying or fluidized bed dipping. The application process is efficient and can be automated, resulting in consistent and uniform coatings. This not only saves time and labor costs but also ensures high - quality finishes.

Send Inquiry to This Supplier

You May Also Like

-

PVC PE-Coated Zigzag Wiggle Wire Making Machine Line, Greenhouse Spring Wire Production EquipmentNegotiableMOQ: 1 Set

-

Automatic/manual Fluidized Bed Dip Powder Coating Equipment Line for Refrigerator Shelves ProductionNegotiableMOQ: 1 Piece

-

Automatic Dip Mould Machine For PVC Plastisol Caps Sleeves Cover RootsNegotiableMOQ: 1 Set

-

Automatic Dip PVC Plastisol Coating Equipment Line For Metal Handles RacksNegotiableMOQ: 1 Set

-

Thermoplastic Dip Polyethylene LDPE Powder Coating For Refrigerator Shelves Grids Basket,Food Grade/REACH/RoHSUS$ 2 - 3MOQ: 1000 Kilograms

-

Food-Safe LDPE Powder Coating for Metal Baskets and Shelves, Superior Corrosion Resistance in Commercial RefrigeratorsUS$ 2 - 3MOQ: 1000 Kilograms

-

Customizable Color Thermoplastic Dip LDPE Powder Coating, Enhances Durability for Household Refrigerator ComponentsUS$ 2 - 3MOQ: 1000 Kilograms

-

Fluidized Bed Dip LDPE Powder Coating for Refrigerator Grids, Operating Range -40°C to 80°C, Hygienic SurfaceUS$ 2 - 3MOQ: 1000 Kilograms

-

REACH/RoHS Compliant Thermoplastic Dip LDPE Powder Coating - Food Grade Protection for Refrigerator Shelves, Grids and Storage BasketsUS$ 2 - 3MOQ: 1000 Kilograms

-

Battery Boxes Use Thermoplastic PE Polyethylene Powder Coating Black RAL9005 High Anti-CorrosionUS$ 2 - 3MOQ: 1000 Kilograms