Crack-Free Wear-Resistant Composite Steel Plate

high hardness wear plate

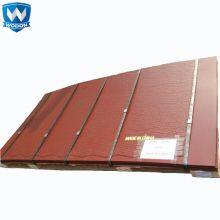

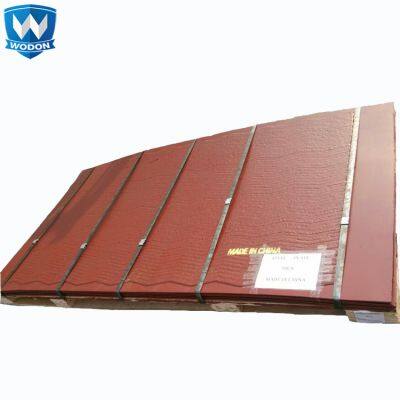

We use our own developed CNC automatic welding machine with multi welding guns to weld our own hardface wear plate. These can overcome the problems like: low productivity, poor flatness and overlay falling off etc. This is a high automation level machine, each welding gun can operate independently and restart exactly from the point it had stopped, simplifying the operation process. The Surface welding plates manufactured by this equipment have many advantages like flat surface, micro and irregular cracks, and uniform hardness being very well accepted by our customers, which like the above picture showing. The following picture shows CNC automatic machine with multi welding guns.

What is Wodon wear plate?

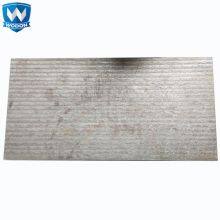

Wodon wear resistant steel plates are manufactured by welding one or multiple abrasion resistant layers on a medium or low carbon steel base plate. The overlay alloy has a high amount of chromium carbide hard particles. These particles are distributed evenly throughout the layer, creating a strong microstructure. The hardness is HRC 58~65 and depends on the overlay's thickness.

The main ingredients of Wodon plate are C (%): 3.0~5.0 and Cr (%): 25~40. This chemical proportion results in a large amount of chrome carbide hard particles. The micro-hardness (up to HV1800) of these particles thoughout the layer will guarantee a super wear resistant surface.

The overlay and base plate are metallurgical bonding. The overlay will penetrate into base plate about 0.8~1.8 mm, reaching up to 350 Mpa in our tests.

| Product name | Wodon high Chromium alloy abrasion resistant steel plate with high hardness |

| Material | Q235/Q345B+Chromium carbide overlay alloy |

| Certificate | ISO9001:2008 |

| Chemical composition | C: 3.0~5.0 % Cr: 25~40 % |

| Microstructure | Chromium carbide hard particles volume fraction above 50 % The maximum hardness of chromium carbide is HV 1800 |

| Wear Resistance | Our test shows that the wear resistance of Wodon plate is 30 times higher than low carbon stell and 12 times than heat treated steel |

| Impact resistance | Wodon wear plates can withstand medium impact |

| Temperature resistance | Wodon wear plates can withstand temperatures up to 600 ℃. We can customize high temperature resistance wear plates according to customer's requirements which can withstand maximum terperatures up to 900 ℃ |

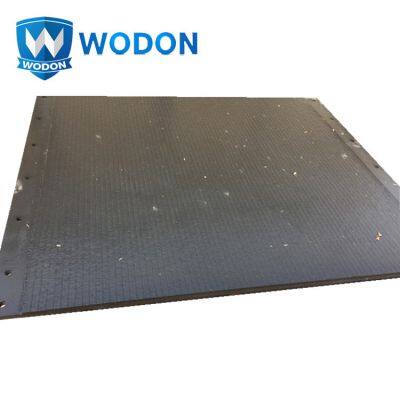

| Flatness tolerance | ± 3 mm/m |

| Thickness tolerance | Uniform overlay thickness, with tolerance within 0~0.5 mm |

| Surface treatment | hardfacing, cladding, open arc or submerged arc welding |

| Standard sizes | Open arc welding: 1400*3400 mm, customized Submerged arc welding: 1400*3000 mm, 1400*3500 mm, 2100*3500 mm, customized |

The main thicknesses (mm) | 3 on 3, 4 on 4, 5 on 5 4 on 6, 5 on 6, 6 on 6, 8 on 6 4 on 8, 5 on 8, 6 on 8, 7 on 8, 8 on 8 4 on 10, 5 on 10, 6 on 10, 7 on 10, 8 on 10, 9 on 10, 10 on 10, 20 on 10 4 on 12, 5 on 12, 6 on 12, 7 on 12, 8 on 12, 10 on 12, 11 on 12, 12 on 12 6 on 14, 8 on 14, 10 on 14 6 on 16, 8 on 16, 10 on 16 6 on 18, 8 on 18, 10 on 18 5 on 20, 6 on 20, 8 on 20, 10 on 20, 20 on 20, 10 on 30, 10 on 40 Customized

|

Wodon wear plates are used to make many complex wear parts to be positioned in high wear places. We have several equipment to transform our plates: six of CNC automatic plasma cutting machine, 4 multi functional bending machines and pressing machines, with high processing capacity operated by engineers and technical experts. We can provide wear plate cutting, bending, punching and welding according to customer's drawings.

We can provide steel pallet design or product the steel pallet according to customer's drawing, so that our product can be safety surpported and easly transported with steel tape and iron ecke. We can provide our product with printing to rust protection.

Our company has a professional after-sales service team, with many years of experience not ony on hardfacing products and applications, but also on the opertion of application equipemt. We are able to quickly solve customer's problems. If there are any quality problems, the responsible person will provide reasonable solutions within 12 hours after being notified.

Q: Are you trading company or manufacturer ?

A: We are manufacturer with more than 3 factorys, our own sales department and our own inspection technology department.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge.

Q: What is your terms of payment ?

A:30% T/T in advance ,balance against copy of BL.

also, FOB, CIF, CFR all are available for your product.

If you have another question, pls feel free to contact us as below:

Send Inquiry to This Supplier

You May Also Like

-

Customized Wear Plates for Cement Mills High-Performance Chromium Carbide Overlay HRC 58-65NegotiableMOQ: 1 Square Meter

-

Wear Plate for Mining Hoppers Chromium Carbide Overlay High Durability Reliable PerformanceNegotiableMOQ: 1 Square Meter

-

Chromium Carbide Wear Plates for Quarry Equipment High Abrasion Resistance Impact ProtectionNegotiableMOQ: 1 Square Meter

-

High Performance Wear Plates for Cement and Mining Chromium Carbide Overlay Customizable SizesNegotiableMOQ: 1 Square Meter

-

Wear Plate for Heavy Equipment Abrasion-Resistant Chromium Carbide Overlay for Mining & CementNegotiableMOQ: 1 Square Meter

-

Bimetallic Wear Plates Durable High Abrasion Resistance for Cement Mills and Mining EquipmentNegotiableMOQ: 1 Square Meter

-

Custom Chromium Carbide Wear Plates Abrasion-Resistant Impact Resistant for Mining and CementNegotiableMOQ: 1 Square Meter

-

Wear Plate for High-Abrasion Applications Chromium Carbide Overlay for Cement and MiningNegotiableMOQ: 1 Square Meter

-

Custom Wear Plates for Industrial Machinery Chromium Carbide Overlay High Hardness & DurabilityNegotiableMOQ: 1 Square Meter

-

Wear Plates for Heavy-Duty Mining Equipment Chromium Carbide Overlay Long-Lasting ProtectionNegotiableMOQ: 1 Square Meter