Squeeze Roller Hardfacing Flux Cored Welding Wire

Squeeze roller hardfacing rutile flux cored welding wire

Scraper conveyor repairing

Roller repairing

Screw converyor repairing

With many years of experience in this feild, we are specialized in researching, developing and producing various wear resistant, gas shielded, flux cored welding wires which can be used for hardfacing all positions in different working conditions, welding efficiency is 3-5 times than welding electrode.

Squeeze Roller Welding Wires

| Model |

Specification (mm) |

Hardness (HRC) |

Main Ingredient | Main Application |

|

WD-ZYG100 (1#) |

1.6,2.8,4.0 | - |

C: 0.03-0.15 Mn: 0.5-2.5 |

Used for squeeze roller backing welding. |

|

WD-ZYG100A (1996) |

1.6,2.8,4.0 | - | C: 0.05-0.15 Cr: 18-22 Ni: 8-11 Mn: 4-7 | Used for squeeze roller backing welding. |

| WD-ZYG200 | 1.6,2.8,4.0 | 20-35 |

C: 3.5-4.6 Cr: 4.0-6.0 Mo: 0.3-1.0 Nb: 0.3-1.0 |

Used for squeeze roller buffer layer. |

| WD-ZYG300 | 1.6,2.8,4.0 | 50-55 |

C: 0.3-1.0 Cr: 5-10 Mo: 0.5-1.5 Nb: 1-3 |

Used for squeeze roller buffer layer. |

| WD-ZYG500 | 1.6 | 55-60 |

C: 0.5-2.5 Cr: 5-10 Mo: 0.5-1.5 Nb: 3-6 |

Used for squeeze roller hardfacing layer. |

1. Chemical Composition: High carbon high chromium

2. Hardness: HRC58-65

3. Good Performance: no clearing slag, low welding spatter, smooth surface, high welding efficiency, stable filling rate, etc.

4. welding wire without any joints.

5. Production Capacity: 8000 tons per year

6. Short Delivery Time: Generally 7 days

7. We have many experienced professionals to research and develop welding wires according to customers' specified chemical compositions.

8. We can recommend proper welding wires and provide technical solutions based on working conditions.

9. on site inspection and third party inspection are available.

10. As an ISO9001:2008 approved manufacture, our mission is to improve our management system and provide high quality products continuously.

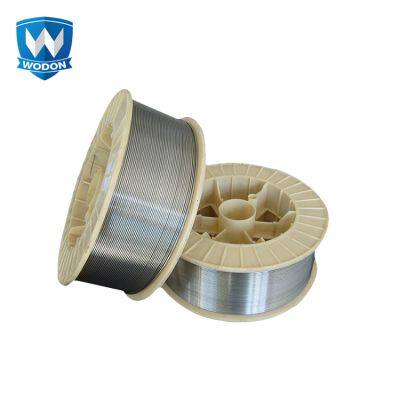

Packaging: 15kgs/coil, 50kgs/coil, 150-250kgs/drum, Steel Pallet, Customized

Packing Size: 1.15m*0.58m*0.88m, 1.15m*1.15m*0.88m, customized

Delivery Detail: Generally 7 days

Packaging

Packaging

Our company has a professional after-sales service team, with many years of experience not only on hardfacing products and applications, but also on the operation of application equipment. We are able to quickly solve customer’s problems.If there are any quality problems, the responsible person will provide reasonable solutions within 12 hours after being notified.

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge.

Q: What is your terms of payment ?

A:30% T/T in advance ,balance against copy of BL.

If you have another question, pls feel free to contact us as below:

Send Inquiry to This Supplier

You May Also Like

-

Hardfacing Soldering Wire WD-D990+ High Temperature Flux Cored Welding WireUS$ 11 - 11MOQ: 1 Kilogram

-

China Factory's Corrosion-Resistant Flux Core Wire for General Welding & Surfacing High Quality Metals & Metal ProductsUS$ 6 - 6MOQ: 1 Kilogram

-

Wodon Abrasion Resistant Heat Resistant Flux Core Welding WireUS$ 8.18 - 8.18MOQ: 1 Kilogram

-

Wodon Customizable OEM Gas Shielding Flux Cored Welding Wire for Surfacing Valve ApplicationUS$ 4.02 - 4.02MOQ: 1 Kilogram

-

Hardfacing Fluxed Cored Welding Wire FCW Wear Resistant for Single Layer Hardfacing WD-D788A 1,2mmUS$ 3 - 3MOQ: 1 Unit

-

Wear Resistant Flux Cored Welding Wires for Wear PlatesUS$ 8 - 8MOQ: 1 Kilogram

-

China Manufacturer's CO2 Gas Shielded Welding Wire Alloy Flux Cored Wire for Soldering From Production LineCAD 300 - 300MOQ: 1 Kilogram

-

HB100 Vertical Cement Mill Welding Wires High Performance for Excellent ResultsCHF 2.5 - 2.5MOQ: 1 Kilogram

-

Wodon Manufactured High Chromium High Carbon Flux Core Wire for Surface Welding Wear PlateUS$ 2.22 - 2.22MOQ: 1 Kilogram

-

HB350 Abrasion Resistant Hardfacing Co2 Welding Wire for Cement Mill Roller Surface RepairUS$ 9 - 9MOQ: 1 Kilogram