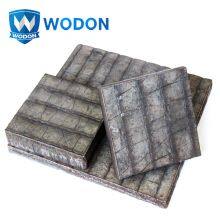

Wodon Factory Hardfacing Overlay Wear Resistant Compound Bimetallic Sheet

wodon factory hardfacing overlay wear resistant compound bimetallic sheet

Product Application

wodon factory hardfacing overlay wear resistant compound bimetallic sheet are manufactured by welding one or multiple wear resistan layers on a medium or low carbon steel base plate.

Our company focuses on power, steel, cement, glass, mining, coal processing, metallurgical machinery, engineering machinery, construction machinery, loading machinery and other industries. The wear resistant steel plate, welding wire, wear resistant welding electrode and wear resistant parts repairing technology have made us to be the leader in this field.

wodon factory hardfacing overlay wear resistant compound bimetallic sheet

wodon factory hardfacing overlay wear resistant compound bimetallic sheet

Main Features

1) the carbide (Cr7C3) volume fraction on the microstructure is above 50% ,

2) surface hardness is 58 to 65HRC , with chromium content of 27% to 40%.

3) The wear resistance of Wodon plate is 20 times higher than low carbon steel and 8 times higher than heat treated wear plate,

4) flatness tolerance is plus/minus 3 mm per meter,

5) thickness tolerance is 0 to 0.5 mm.

Product Name | wodon factory hardfacing overlay wear resistant compound bimetallic sheet |

Brand | Wodon |

Base Plate | Q345 |

Hardfacing layer | High chromium high carbide overlay |

Chemical Composition | C(%): 3.0-5.0 ,Cr(%): 25-40. |

Microstructure | The carbide (Cr7C3) volume fraction on the microstructure is above 50%. |

Hardness | HRC58-65. |

Surface Treatment | Hardfacing,clading,coated. |

Technique | Hardfacing,open arc welding,submerged arc welding. |

Wear Resistance | High wear resistance,30 times higher than low carbon steel and 12 times than heat treated steel. |

Impact Resistance | Medium |

Flatness tolerance | ±3mm/m |

Thickness tolerance | Uniform overlay thickness, with tolerance within 0-0.5mm. |

Main Thicknesses | 3+3,4+4, 5+5 6+4,6+5,6+6,6+8 8+4,8+5,8+6,8+7,8+8 10+4,10+5,10+6,10+7,10+8,10+9,10+10,10+20 12+4,12+5,12+6,12+7,12+8,12+10,12+11,12+12 14+6,14+8,14+10,16+6,16+8,16+10 18+6,18+8,18+10,20+5,20+6,20+8,20+10,20+20,30+10,40+10 Customized. |

Plate Size | Open arc welding wear plate:1400*3400mm Submerged arc welding wear plate:1400*3000mm, 1400*3500mm, 2100*3500mm. Customized. |

Place of Origin | China |

Application | Mining,Steel,Cement,Power,Port,etc. |

We have our own Quality Inspection Technology Department and the team are made of many experience exports with material science bachelor-degree and the leaders with material science master-degree. In the pictures you can also see our equipment in our laboratory. Our inspection team make regular testing on raw material, production process and our products according our company's strict policy.

The above picture shows our laboratory. There are many equipments to suppert our Quality Inspection Technology Department, for sample: a series of metallographic analysis equipments, protable spectrum, protable ultrasonic thickness tester, protable ultrasonic hardness tester, destop Rockwell hardness tester, Infrared carbon sulfur analyzer, Quartz sand rubber wheel abrasion test machine and Reciprocating abrasion tester.

Our company has a professional after-sales service team, with many years of experience not ony on hardfacing products and applications, but also on the opertion of application equipemt. We are able to quickly solve customer's problems. If there are any quality problems, the responsible person will provide reasonable solutions within 12 hours after being notified.

Q: Are you trading company or manufacturer ?

A: We are manufacturer with more than 3 factorys, our own sales department and our own inspection technology department.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge.

Q: What is your terms of payment ?

A:30% T/T in advance ,balance against copy of BL. FOB, CIF, CFR all are available for your product.

If you have another question, pls feel free to contact us as below:

Send Inquiry to This Supplier

You May Also Like

-

Wodon Chromium Carbide Hardened Steel Plate With Super Wear ResistanceUS$ 300 - 300MOQ: 1 Square Meter

-

Chromium Carbide Overlay Wear Resistant Plates for Mining IndustryUS$ 200 - 200MOQ: 1 Square Meter

-

Abrasion Resistant Plates for Cement Mining Glass Thermal Power Sand Gravel RecyclingUS$ 200 - 200MOQ: 1 Square Meter

-

High Chromium Abrasion Resistant Plates for Metallurgy Asphalt Power Quarry PetroleumUS$ 200 - 200MOQ: 1 Square Meter

-

Overlay Compound Bimetallic Wear Resistant Plates for Mining Transportation VehiclesUS$ 200 - 200MOQ: 1 Square Meter

-

High Hardness 60-65 HRC Wear Resistant Composite Welded Wear Steel PlateUS$ 300 - 300MOQ: 1 Square Meter

-

CCO Bimetal Plates for Mining Transportation Vehicles Rail Cars Garbage TrucksUS$ 360 - 360MOQ: 1 Square Meter

-

ASTM G65 Chromium Carbide Overlay CCO Wear Resistant Plates for Engineering MachineryUS$ 299.99 - 299.99MOQ: 1 Square Meter

-

Hardfacing Bimetal Steel Wear Resistant Plate 58-63 HRC - Ideal for Mining & Construction EquipmentUS$ 140 - 1000MOQ: 1 Square Meter

-

Chromium Carbide Overlay Wear Resistant Hardfacing Steel Plate With High HardnessUS$ 135 - 135MOQ: 1 Square Meter