CNC Precision Automatic Lathe Adjustable Collet Chuck to Ensure Short Workpiece Clamp Tightly and StablyNot Required Large Diameter Ground Bar Stocks Shortening Remnant, and Reducing Material Cost

E-mail :dgyuanjieshiye@163.com

Model overview

0. Support personalization

1. Origin: China

2. The diameter of the machining : Φ02-Φ52mm

3. Double spindle

4. Main axis: (China) personalized customization

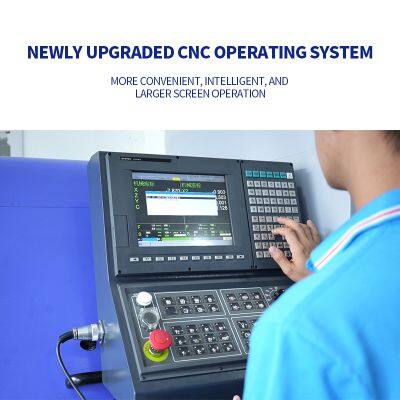

5. System: (personalized support)

6 .Accuracy: 0.01mm,See part definition

7. Electrical components: Schneider, support personalization

8. X1 shaft, X2 shaft, Y1 shaft, Y2 shaft:, Z1 shaft, Z2 shaft ,Bshaft(personalized support)

9. A set of solutions to complex, precise and minute details of the parts one-time molding

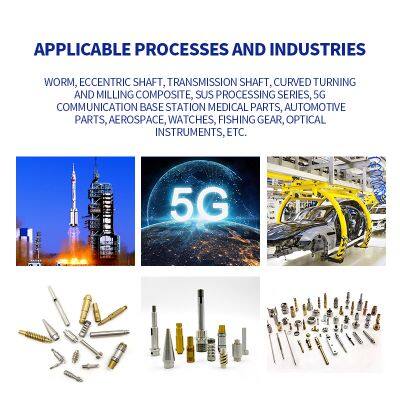

10. Composite material processing: turning, milling, drilling, thread cutting

11. Modular tool layout, multi-axis combination operation; Stable, high speed, high efficiency, easy to operate

Send Inquiry to This Supplier

You May Also Like

-

Vertical Gang Tool CNC Lathe 32 Mm, 5-Axis Vertical Gang Tool CNC LatheNegotiableMOQ: 1 Unit

-

Multifunction Turn/Mill Turning Centers 38 mm Multifunction Turning CenterNegotiableMOQ: 1 Unit

-

Independent Gang Slide Swiss Type Lathes 6- Axis Split Slide Swiss CNC LatheNegotiableMOQ: 1 Unit

-

Swiss Turn Lathes Axis 6 - 38 Mm, Chucker-convertible Sliding Headstock Lathe With B-AxisNegotiableMOQ: 1 Unit

-

CNC Lathe Large Inch Fanuc Automatic Cast Iron Bed CNC Lathe Multislide With Turning Tool Sleeve on SaleChinese Manufacturer YUANJIE CNCNegotiableMOQ: 1 Unit

-

Automatic Sliding Headstock Type Cnc Metal LatheChinese Manufacturer YUANJIE CNCNegotiableMOQ: 1 Unit

-

Double Spindle Multifunctional Swiss CNC Lathe Machine Mini Hydraulic Hose Crimping CNC Machine 5 Axis Lathe For Processing MChinese Manufacturer YUANJIE CNCNegotiableMOQ: 1 Unit

-

Ouble Spindle Swiss CNC Lathe CNC Milling Turning Parts Mini Automatic CNC Lathe For Metal-workingChinese Manufacturer YUANJIE CNCNegotiableMOQ: 1 Unit

-

Ouble Spindle Swiss CNC Lathe CNC Milling Turning Parts Mini Automatic CNC Lathe For Metal-workingChinese Manufacturer YUANJIE CNCNegotiableMOQ: 1 Unit

-

Double Spindle Multifunctional Swiss CNC Lathe Machine Mini Hydraulic Hose Crimping CNC Machine 5 Axis Lathe For Processing MChinese Manufacturer YUANJIE CNCNegotiableMOQ: 1 Unit