Cement Mill’s Key Liner in Building: Excel Wear Liners for Quality Grinding

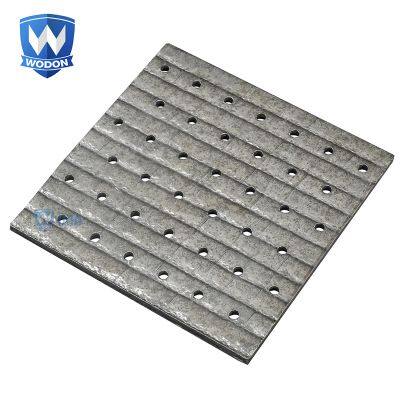

Tianjin WODON hardfacing welding CCO bimetallic wear resistant steel plates

Chromium carbide composite cladding fusion bonded to a mild steel backing material.

The deposit has been realized by means of oscillated welding and a wear resistant coating applied by submerged arc welding.

Fine cracks perpendicular to the welding bead is normal due to natural stress relieving in a very hard matrix.

Very high volume of chromium carbides evenly distributed throughout the uniform thickness of the deposit.

Plate hardness ranges from HRC58-65.

Suitable for applications involving high abrasion and low to medium impact.

AS2576-2355/2576-2455

Supported by patent technique, Wodon high chromium carbide overlay wear plates are manufactured under tightly controlled parameters within a quality management system. Various thickness is available.

Specification

| Thickness(backing plate + weld overlay) | L x W (mm) |

| 4+4, 5+5 4on4, 5on5 | 1,400 x 3,000 |

| 6+6, 8+5, 8+6, 8+7, 8+8, etc 6on6, 5on8, 6on8,7on8, etc | 1,400 x 3,500 |

| 10+8, 10+9, 10+10, 10+20, 12+12, 12+20, 12+32, 12+50,14+26, 14+32, 20+30, customized thickness 8on10, 9on10, 10on10, 20on10, 12on12, 20on12, 32on12, 50on12, 26on14, 32on14, 30on20 etc | 1,400 x 3,500 2,100 x 3,500 |

| C | Si | Mn | Cr | Others | Fe |

| 3.5-6.0 | 1.0-3.0 | 1.0-3.0 | 27-40 | Mo Nb V W Ni B etc | Balance |

Product nameWodon High Chromium High Carbon Wear Resistant PlateMaterialQ235/Q345+Chromium carbide overlay alloyCertificateISO9001:2008Chemical compositionC: 3.0~5.0 % Cr: 25~40 %MicrostructureChromium carbide hard particles volume fraction above 50 %

The maximum hardness of chromium carbide is HV 1800Wear ResistanceOur test shows that the wear resistance of Wodon plate is 30 times higher than low carbon stell and 12 times than heat treated steelImpact resistanceWodon wear plates can withstand medium impactTemperature resistanceWodon wear plates can withstand temperatures up to 600 ºC. We can customize high temperature resistance wear plates according to customer's requirements which can withstand maximum terperatures up to 900 ºCFlatness tolerance± 3 mm/mThickness toleranceUniform overlay thickness, with tolerance within 0~0.5 mmSurface treatmenthardfacing, cladding, open arc or submerged arc weldingStandard sizesOpen arc welding: 1.4*3.4 m, 1.5*3.0 m and 2.0*3.0 m, customized

Submerged arc welding: 1400*3000 mm, 1400*3500 mm, 2100*3500 mm, customizedThe main thicknesses

(mm)3 on 3, 4 on 4, 5 on 5

4 on 6, 5 on 6, 6 on 6, 8 on 6

4 on 8, 5 on 8, 6 on 8, 7 on 8, 8 on 8

4 on 10, 5 on 10, 6 on 10, 7 on 10, 8 on 10, 9 on 10, 10 on 10, 20 on 10

4 on 12, 5 on 12, 6 on 12, 7 on 12, 8 on 12, 10 on 12, 11 on 12, 12 on 12

6 on 14, 8 on 14, 10 on 14

6 on 16, 8 on 16, 10 on 16

6 on 18, 8 on 18, 10 on 18

5 on 20, 6 on 20, 8 on 20, 10 on 20, 20 on 20, 10 on 30, 10 on 40, and Customized

Why our wear plate has such good wear resistance?

1. The overlay chemical composition is the key

The main ingredients of Wodon plates are C(%) :3.0-5.0 and Cr(%):25-45. This chemical proportion results in a large amount of Cr7C3 chrome carbide hard

particles. The micro-hardness (up to HV1800) of these particles throughout the layer will guarantee a super wear resistant surface.

Performance test:

Test equipment: Quartz sand rubber wheel abrasion test machine.

Conditions: Choosing same dimension specimens for different materials and wear plate producers, and put them under the same wearing working conditions

in our testing equipment.

45 minutes for each specimen.

No. | Wear Plate Type | Test Time | Weight Loss of Overlay |

1 | Wodon Wear Plate | 45 minutes | 0.148g |

2 | Imported Wear Plate | 45 minutes | 0.229g |

3 | Imported Wear Plate | 45 minutes | 0.237g |

4 | Imported Wear Plate | 45 minutes | 0.252g |

5 | Domestic Wear Plate | 45 minutes | 0.385g |

6 | Domestic Wear Plate | 45 minutes | 0.377g |

7 | Domestic Wear Plate | 45 minutes | 0.399g |

8 | Domestic Wear Plate | 45 minutes | 0.371g |

Results: The test results show that the life span of Wodon wear plate is 2.5 times higher than domestic wear plates and 1.5 times than imported ones.

2. Chromium carbide microstructure

The wear resistance of wear plate depends mostly on the hardness, shape, size, amount and distribution of the chromium carbide hard particles.

3. Bonding strength between the overlay and base plate.

The overlay and base plate are very well bonding. The overlay will penetrate into base plate about 0.8mm-1.8mm, reaching up to 350Mpa in our tests.

Wear Part Production

Cutting

Overlay can be cut with plasma, laser, and water jet.

Machining

The overlay surface is not machinable. However, Wodon can provide Overlay with countersink holes and tapped holes.

Forming

Overlay can be cold formed or rolled.

Welding

Overlay can be welded on the mild steel base plate surface.

Our production capacity of wear parts is 7,000 tons per year.

Tianjin Wodun abrasion-resistant products are widely adapted to key equipment across multiple industries, enhancing wear resistance, optimizing operational efficiency, and reducing maintenance costs.

1. Mining Industry

1. Crushers

- Jaw Crusher: Jaw plates use Wodun abrasion-resistant plates to withstand strong compressive forces and impacts during ore crushing, ensuring durability and reducing frequent replacements.

- Cone Crusher: Crushing wall and bowl liners use Wodun abrasion-resistant materials, offering impact resistance and extended lifespan in high-speed crushing operations.

2. Ball Mill

- Barrel Liners: Protect the barrel from grinding and impact from steel balls and ores, ensuring stable grinding conditions and reducing equipment failure.

- End Liners: Provide excellent sealing and wear resistance to prevent material leakage and extend the overall lifespan of the ball mill.

2. Cement Industry

1. Vertical Mill

- Roller: Covered with Wodun abrasion-resistant plates, customized for high-pressure grinding of cement raw materials, offering wear and fatigue resistance to ensure production efficiency.

- Table Liners: Ensure stable pressure bearing and reduce wear, maintaining continuous operation of the vertical mill.

3. Steel Industry

1. Sintering Machine

- Car Side Panels: High-temperature and wear-resistant Wodun plates resist friction and impact from sintering materials, ensuring normal operation of the car.

- Annular Cooler Discharge Scrapers: Effectively scrape cooled sinter with wear-resistant properties, reducing maintenance frequency.

4. Metallurgical Industry

1. Converter

- Mouth: Special Wodun abrasion-resistant plates protect against high-temperature steel, slag, and gas erosion, reducing hot repairs and ensuring smelting stability.

- Ladle Lining: Enhances resistance to impact and erosion, extending the lifespan of the ladle and ensuring casting quality.

5. Machinery Industry

1. Construction Machinery (Loader, Bulldozer)

- Loader Bucket: Bucket teeth and walls use Wodun abrasion-resistant plates to improve wear resistance during material excavation, enhancing operational efficiency.

- Bulldozer Blade: Relies on abrasion-resistant plates to withstand high-intensity friction during dozing, reducing replacements and ensuring reliability.

6. Port Industry

1. Loading and Unloading Cranes

- Grab Bucket: Teeth and inner walls use Wodun abrasion-resistant plates to ensure efficient and leak-free handling of bulk materials.

- Pulley Grooves: Liners reduce wire rope wear, ensuring safe and smooth cargo hoisting.

2. Conveying Equipment

- Belt Conveyor Rollers: Covered with abrasion-resistant plates to prevent wear-induced belt misalignment, ensuring stable operation.

- Chutes: Liners allow smooth material flow, avoiding damage from impact and maintaining efficient logistics operations.

Send Inquiry to This Supplier

You May Also Like

-

High Chromium Alloy Surfacing Wear-resistant PlateUS$ 200 - 300MOQ: 1 Square Foot

-

Special Wear-resistant Steel Plates for Cement PlantsUS$ 200 - 300MOQ: 1 Square Foot

-

6 + 4 Surfacing Wear-resistant Steel PlateUS$ 200 - 300MOQ: 1 Square Foot

-

8 + 8 Surfacing Wear-resistant Steel PlateUS$ 200 - 300MOQ: 1 Square Foot

-

High-temperature Resistant and Wear-resistant Steel PlateUS$ 200 - 300MOQ: 1 Square Foot

-

Submerged Arc Welding Composite Wear-resistant Steel PlateUS$ 200 - 300MOQ: 1 Square Foot

-

Bimetal Composite Surfacing Wear-resistant Steel PlateUS$ 200 - 300MOQ: 1 Square Foot

-

Wear-resistant Steel Plate for Construction MachineryUS$ 200 - 300MOQ: 1 Square Foot

-

Premium Wear-Resistant Plates for Forklift Buckets: Unbeatable Durability for Heavy-Duty Material HandlingUS$ 200 - 300MOQ: 1 Square Foot

-

6 + 4 Wear-Resistant Plate: High-Performance Solution for Enhanced DurabilityUS$ 200 - 300MOQ: 1 Square Foot