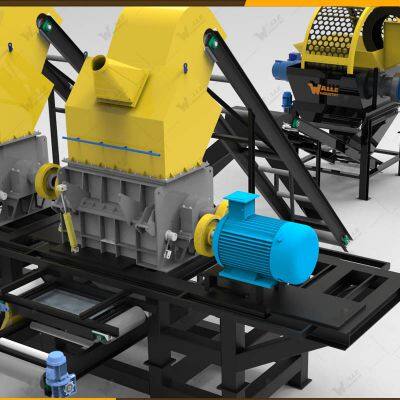

Walle Industry Tire Mulching Machine Tire Waste Recycling Machine Tire Rubber Powder Making Recycling Machine

waste tire recycling machine is used to all kinds of tyre, such as the truck tire, car tire, soild tire,OTR tyre etc. Make them becomes as the TDF as the material for the new energy, or crushing as the fineness rubber powder, as the raw material of new tyre, or the football playground, or as the new rubber block through the melting. it as also could be as the raw material of the rubber plate to reduce the shaking or others.

characters:

1.The full autoamtic controlled by the PLC system.

2. The whole system is environmental friendly, there is fit the filter dust removal. 3. High efficiency processing by the physical mechinical method.

4. Low noise

5. The finals products is as customer requirement

working principle

the waste tire or rubber belt will be removed the tyre beader, after that the rubber rim will be put into the three in one rubber processing machine to cutting them into smaller chips, the outcomes size is approx 50-100mm. the secondary is the two rollers grinder machine to cut the material into powder with the chips, the vibration table will sort the rubber powder out, the magnetic separator will sort the Steel wire out, the 2th vibration table to remove the Nylon from the material. magnetic separator box will remove the rest steel wire from the rubber material, then collecting by the jumbo bags system. if the material is the Radial Nylon tire, the material of Nylon connected by the cyclone with the blower.

The rubber purity could reach 99%, the wire parts purity approx 98%.

Technical parameters

| Type | power | Cutter Qty PCS | reducer | chamber mm | feeding port | overall size mm | weight T | capacity (T/h) |

| WL-800 | 15kw*2 | 30 | 400 | 600*388 | 1000*766 | 1820*800*1930 | 2.1 | 0.5-0.8 |

| WL-1000 | 22kw*2 | 20 | 500 | 640*588 | 1170*990 | 3260*1300*2370 | 3.5 | 1-1.5 |

| WL-1200 | 37kw*2 | 30 | 355 | 1200*788 | 1600*1200 | 4700*2000*2700 | 8 | 2.5-3 |

| WL-1500 | 55kw*2 | 30 | 400 | 1500*1188 | 1900*1450 | 5000*2200*2900 | 18 | 8-10. |

| WL-1800 | 75KW*2 | 36 | 400 | 1800*1188 | 2300*1450 | 5300*2150*3000 | 20 | 12-15. |

| WL-2000 | 90kw*2 | 24 | 450 | 2000*1188 | 2300*1500 | 5400*2150*3000 | 25 | 20-25. |

| WL-2200 | 110kw*2 | 28 | 240 | 2200*1578 | 3100*2500 | 6200*2700*3500 | 33 | 26-30 |

| WL-2400 | 132kw*2 | 24 | 240 | 2400*1678 | 3200*2600 | 7300*2800*3800 | 38 | 30-35. |

| WL-2800 | 185kw*2 | 28 | 260 | 2800*2000 | 3700*3000 | 7800*2800*3800 | 45 | 35-40 |

Tire steel wire debeader

To remove the thick steel from the rubber, to ensure that the uptime in operation, meanwhile to recycle the most steel wrie of the rubber.

type WL1200 WL1600 power 11 kw 22kw capacity 20-60 Pcs/h 60-80 pcs/h hook type Single hook cylinder 1200 mm 1600mm weight 2800 kgs 3600kgs size 2800*900*1760mm 3500*1100*1760mm

Send Inquiry to This Supplier

You May Also Like

-

Walle Industry Pyrolysis Tire Shredder Pyrolysis Rubber Shredding Machine Tyre Shredder for PyrolysisUS$ 18500 - 56200MOQ: 1 Set

-

WL-1600 TDF Shredder RDF Shredder RDF Shrdding MachineUS$ 55000 - 98000MOQ: 1 Set

-

WL-1600 Garbage Shredder Household Waste Shredder MSW Recycling AmchineUS$ 55000 - 98000MOQ: 1 Set

-

Walle Industry Mattress Shredder Sofa Shredder Mattress Waste Crusher MachineUS$ 55000 - 98000MOQ: 1 Set

-

Walle Industry Domestic Waste Shredder Furniture Waste ShredderUS$ 55000 - 98000MOQ: 1 Set

-

WL-1600 Domestic Waste Shredder Kitchen Waste Shredder Garbage Waste Recycling MachineUS$ 55000 - 98000MOQ: 1 Set

-

Large Furniture Waste Cans Rubber Sofa Metal Waste Plastic Bottle Carton Cardboard Box Shredder Machine for SaleUS$ 55000 - 98000MOQ: 1 Set

-

Waste Cloth Pipe Barrel Bottle Film Disk Cardboard Waste Plastic Shredder Machine With CEUS$ 55000 - 98000MOQ: 1 Set

-

Hydraulic Scrap Double Shaft Waste Plastic Recycling Waste Plastic Bottle Shredder Machine for SaleUS$ 55000 - 98000MOQ: 1 Set

-

Scrap Two Shaft Waste Shredder Plastic Bottle Cardboard Waste Plastic Shredder MachineUS$ 55000 - 98000MOQ: 1 Set