X/Y/ZTravel: 900×600×600mm

TableDimensions: 1000×600mm

Max.TableLoad: 600Kg

SpindleFacetoWorktableHeight: 120—720mm

PositioningAccuracy: ±0.005/300mm

Repeatability: ±0.003/300mm

ToolCapacity: 24

SpindleSpeed: 15000-40000Rpm

MovingSpeed: 24m-36m/min

CuttingSpeed: 10m-20m/min

ToolChangeTime: 2seconds

Dimensions(L/W/H): 2800×2700×3100mm

MachineToolWeight: 5000Kg

ControlMethod: Fullyclosed-loopcontrol

If necessary, please contact me WhatsAPP:8613510109008,

Email:sales@ssjjcnc.ru.

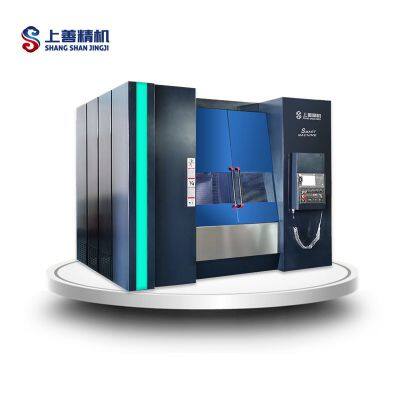

Looking for high-speed gantry machining of graphite to achieve precision and efficiency in your production process? Our High-Speed Gantry Machining of Graphite services and equipment are designed to meet the stringent demands of industries such as electronics, aerospace, automotive, and tooling, where precision and speed are critical. Using advanced CNC gantry machining technology, we offer unparalleled performance for machining complex graphite components like electrodes, molds, prototypes, and custom parts with high accuracy and excellent surface finishes.

The gantry-style machining system ensures optimal rigidity, stability, and vibration damping, allowing for high-speed machining even with delicate graphite materials. With the ability to perform multi-axis operations such as milling, drilling, cutting, and shaping, our high-speed gantry machining centers are ideal for producing graphite electrodes for EDM (Electrical Discharge Machining), graphite molds, and high-precision graphite parts.

Key Features:

High-speed gantry machining for fast, precise removal of graphite material, ensuring smooth and accurate cuts.

2.Advanced CNC control for multi-axis machining, delivering high precision and versatility for complex graphite parts.

3.Superior stability with a gantry-style design, minimizing vibrations for superior surface finishes and tight tolerances.

4.Large working area that accommodates oversized graphite components, making it ideal for high-volume production.

5.Dust management system to reduce graphite dust in the workspace, ensuring a safer and cleaner environment.

6.Versatile applications including the production of graphite electrodes, molds, prototypes, and custom components.

Whether you're machining graphite electrodes for EDM applications, creating intricate graphite molds, or producing custom graphite parts, our high-speed gantry machining of graphite delivers precision, reliability, and high efficiency. This advanced machining technology is a must-have for industries demanding the highest quality graphite machining solutions with quick turnaround times.

Send Inquiry to This Supplier

You May Also Like

-

Graphite Engraving Machine S-1100VNegotiableMOQ: 1 Unit

-

Graphite Engraving Machine Processing Unit S-1500VNegotiableMOQ: 1 Unit

-

Graphite Machine Equipment S-500VNegotiableMOQ: 1 Unit

-

High-Speed Graphite Machine S-640VNegotiableMOQ: 1 Unit

-

Graphite Engraving and Milling Machine S-960VNegotiableMOQ: 1 Unit

-

Graphite CNC S-1100VNegotiableMOQ: 1 Unit

-

Precision Machining of Graphite S-1500VNegotiableMOQ: 1 Unit

-

CNC for Graphite S-500VNegotiableMOQ: 1 Unit

-

Machining Graphite With Machine Tool S-640VNegotiableMOQ: 1 Unit

-

Engraving and Milling Machine Tool for Graphite S-500VNegotiableMOQ: 1 Unit