X/Y/ZTravel: 1100×600×700mm

TableDimensions: 1200*600mm

Max.TableLoad: 800Kg

SpindleFacetoWorktableHeight: 120—820mm

PositioningAccuracy: ±0.005/300mm

Repeatability: ±0.003/300mm

ToolCapacity: 24

SpindleSpeed: 15000-20000Rpm

MovingSpeed: 24m-36m/min

CuttingSpeed: 10m-20m/min

ToolChangeTime: 2seconds

Dimensions(L/W/H): 3150×2750×3700

MachineToolWeight: 6000Kg

ControlMethod: Fullyclosed-loopcontrol

If necessary, please contact me WhatsAPP:8613510109008,

Email:sales@ssjjcnc.ru.

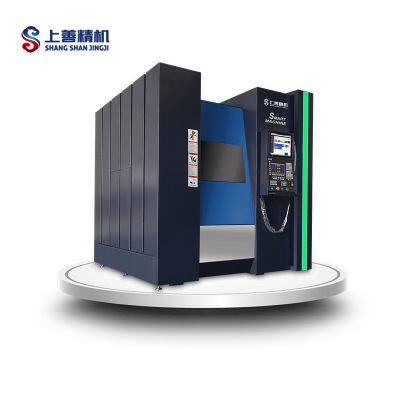

Looking for a Graphite Electrode CNC Machining Center that combines high precision, speed, and durability? Our Graphite Electrode CNC Machining Centers are engineered to provide exceptional performance in the machining of graphite electrodes, crucial for industries such as steel production, electronics, automotive, and aerospace. These advanced machining centers are optimized for producing complex graphite electrodes, which are used in electric arc furnaces (EAF) for steel manufacturing and various high-temperature applications.

Equipped with state-of-the-art CNC technology, our Graphite Electrode CNC Machining Centers ensure precise control for intricate milling, drilling, and shaping of graphite electrodes. The high-speed spindles enable rapid material removal, significantly reducing cycle times and increasing production efficiency. With integrated dust collection systems, these machines effectively capture graphite dust, promoting a cleaner, safer workspace and reducing maintenance needs.

Key Features:

Advanced CNC control for high-precision, repeatable graphite electrode machining

2.High-speed spindles for quick material removal and reduced machining time

3.Efficient dust collection systems to maintain a clean and safe working environment

4.Heavy-duty construction designed to handle the unique challenges of graphite electrode machining

5.Versatile capabilities for producing electrodes in various sizes and shapes

6.Excellent surface finishes and tight tolerances for high-quality, precision graphite electrodes

Our Graphite Electrode CNC Machining Centers are built for high-precision applications, whether you need to produce small batches or scale up for high-volume production. These machines provide the reliability, efficiency, and precision needed to meet the most demanding machining requirements.

Send Inquiry to This Supplier

You May Also Like

-

5-Axis CNC Machining Centers S-1500VNegotiableMOQ: 1 Unit

-

Vertical 3-Axis Machining Centers S-500VNegotiableMOQ: 1 Unit

-

Graphite Carving 3 Axis CNC Machine S-640VNegotiableMOQ: 1 Unit

-

LARGE SIZE 5-AXIS MACHINING CENTER S-960VNegotiableMOQ: 1 Unit

-

Longmen Graphite Machine Center S-1100VNegotiableMOQ: 1 Unit

-

CNC Graphite Milling S-1500VNegotiableMOQ: 1 Unit

-

Gantry Graphite CNC Machining Equipment S-500VNegotiableMOQ: 1 Unit

-

Gantry Style Graphite Machining Center S-640VNegotiableMOQ: 1 Unit

-

Gantry Graphite CNC Cutting Machine S-960VNegotiableMOQ: 1 Unit

-

Gantry Graphite CNC Milling and Machining Center S-1100VNegotiableMOQ: 1 Unit