X/Y/Z Travel: 900×600×600mm

Worktable Dimensions: 1000×600mm

Worktable Load Capacity: 600Kg

Spindle Face to Worktable Height: 120—720mm

Positioning Accuracy: ±0.005/300mm

Repeatability: ±0.003/300mm

Tool Magazine Capacity: 24

Spindle Speed: 15000-40000Rpm

Moving Speed: 24m-36m/min

Cutting Speed: 10m-20m/min

Tool Change Time: 2 seconds

Machine Tool Dimensions: 2800×2700×3100mm

Machine Tool Weight: 5000Kg

Control Method: Fully closed-loop control

If necessary, please contact me WhatsAPP:8613510109008,

Email:sales@ssjjcnc.ru.

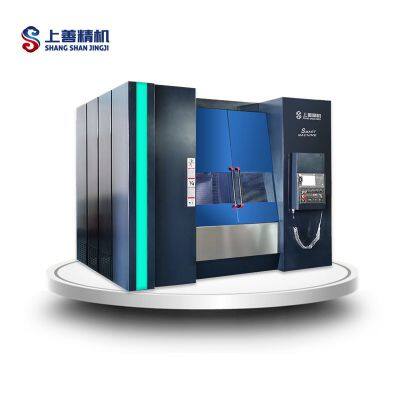

5-Axis CNC Machining Center for Graphite

Our 5-Axis CNC Machining Center for Graphite is engineered for precision and efficiency in the machining of graphite and carbon-based materials. This advanced machining center utilizes 5-axis simultaneous movement to achieve complex geometries, intricate details, and high-quality finishes with unparalleled accuracy.

Key Features:

Precision Engineering: Offers high-speed machining capabilities with precision tolerances, ideal for complex parts in industries such as aerospace, automotive, electronics, and mold making.

2.Graphite-Compatible Design: Specifically designed to handle the unique properties of graphite, including its abrasiveness and tendency to create fine dust during machining, ensuring smooth operation and extended tool life.

3.High-Performance Spindle: Equipped with a powerful spindle that delivers consistent cutting forces and superior surface finishes, even at high speeds.

4.Advanced Control System: Features a state-of-the-art CNC control system, providing intuitive programming, real-time monitoring, and enhanced user interface for ease of use and optimal performance.

5.Dust Management: Integrated dust extraction system to effectively capture graphite dust, ensuring a cleaner workspace and reducing wear on machine components.

6.Flexible Clamping and Tooling: Capable of accommodating a variety of workpiece sizes and shapes with customizable fixtures and tooling options, offering versatility for diverse machining needs.

Applications:

7.Precision molds and dies for electronics, automotive, and medical industries.

8.Complex aerospace components, including structural and engine parts.

9.Prototyping and production of high-performance parts requiring tight tolerances and smooth finishes.

This 5-Axis CNC Machining Center for Graphite delivers outstanding productivity, precision, and reliability, making it the ideal solution for demanding applications in industries that require high-quality graphite components.

Send Inquiry to This Supplier

You May Also Like

-

Graphite Machining Center Vertical Milling S-1100VNegotiableMOQ: 1 Unit

-

Machine Graphite Vertical Cnc Machining Center S-1500VNegotiableMOQ: 1 Unit

-

China Graphite Machining Center S-500VNegotiableMOQ: 1 Unit

-

High Precision Graphite Milling S-640VNegotiableMOQ: 1 Unit

-

Graphite Milling Center S-960VNegotiableMOQ: 1 Unit

-

GRAPHITE ELECTRODE PROCESSING CENTER S-1100VNegotiableMOQ: 1 Unit

-

Graphite Processing Centers S-1500VNegotiableMOQ: 1 Unit

-

3D Milling Machines for Graphite Processing S-500VNegotiableMOQ: 1 Unit

-

CNC Machining Center for Graphite Processing S-640VNegotiableMOQ: 1 Unit

-

Premium Quality Machine for Graphite Processing S-960VNegotiableMOQ: 1 Unit