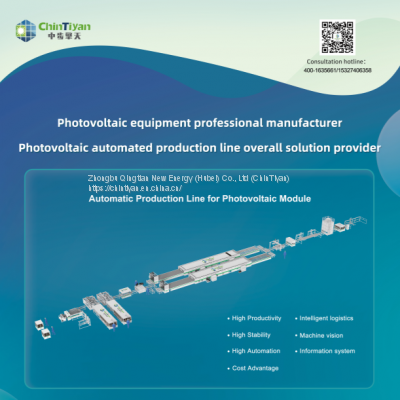

Best Solar Panel Photovoltic System Big Production Assembly Line

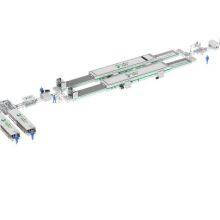

Turnkey solution

Compatible size

a. standard length 1640-2200mm,width 950-1200mm;

b. other specs customized

Compatible module

a. 5BB,MBB,IBC,MWT,HJT,N-TYPE

b. full-cell,half-cut,shingling

c. framed,framed(no C side),frameless

d. glass-backsheet,dual-glass/bifacial,ultra-light,thin-film module

How to build a solar plant? Many customers have this idea, but they don't know what machine they need, so the project did not start.

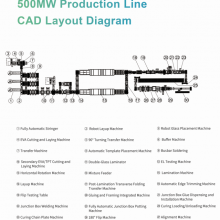

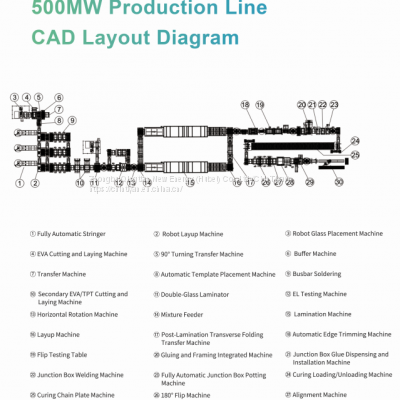

So, What Machines are Included in 100MW Full Auto Solar Panel Production Line Solar Panel Making Machines

2. How To Make 100MW Full Auto Solar Panel Production Line Solar Panel Making Machines:

Step 1: Test solar cell efficiency: make sure the same power cell to be used in one solar panel;

Step 2: Cut complete solar cell into small pieces;

Step 3: Welding solar cell: welding solar cell to string solar cell;

Step 4: Cutting EVA/TPT: according to the solar panel size to cut the EVA and TPT in the designed size;

Step 5: Lay up: achieve solar string automatic laying on glass EVA, and transporting module to the next process;

Step 6: Visual inspect: check the dirty for the Raw materials;

Step 7: Defect check: uses the EL tester machine to identifying micro-cracks, broken finger wires, and other invisible defects in solar modules;

Step 8: Lamination: after EL tester checking the defects, use solar panel Laminate the raw material into solar panel;

Step 9: Trimming: when the Solar panel get cooling after coming out from laminator, It need Cutting the edges, we call Trimming;

Step 10: Glue: use sealant to glue up on aluminum frame;

Step 11: Framing: use the framing machine to install the aluminum frame;

Step 12: Glue: fill the sealant to aluminum alloy after framing;

Step 13: Install junction box: glue the junction box and install it on the solar panel;

Step 14: IV Test: use solar simulator to test the finished solar panel Electrical performance test like power, current etc and record;

Step 15: Test the panel withstand voltage insulation;

Step 16: Defect check: uses the EL tester machine to identifying micro-cracks, broken finger wires and other invisible defects of finished solar modules;

Step 17: Label;

Step 18: Clean the surface and package.

Send Inquiry to This Supplier

You May Also Like

-

China Product Germany Import Pump Production Line of Solar PanelsNegotiableMOQ: 1 Ton

-

Turnkey Price China Product Cheap Full-Auto Machine Solar Cell Production LineNegotiableMOQ: 1 Bag

-

100MW Fully Automatic Solar Cell Laminator Solar Panel Production LineNegotiableMOQ: 1 Bag

-

90MW 100MW Full Automatic Solar Panel Making Production LineNegotiableMOQ: 1 Bag

-

Factory Price Automatic Solar Panel Small PV Production LineNegotiableMOQ: 1 Short Ton

-

Flexible Solar Panel Available Energy System 30MW 60MW Solar Panel Production LineNegotiableMOQ: 1 Short Ton

-

50MW Solar Module Manufacturing Project Turnkey Solar Panel Production LineNegotiableMOQ: 1 Bag

-

20-60MW Production Line Solar Panel Solar Making MachineNegotiableMOQ: 1 Bag

-

Solar Panel Manufacturing Machines 10-30MW Solar Panel Production Line AutomaticNegotiableMOQ: 1 Bag

-

Cheap Automatic Solar Panel Production Line Solar Panel Manufacturing MachinesNegotiableMOQ: 1 Short Ton