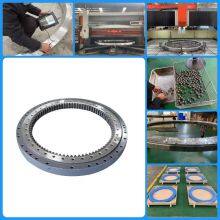

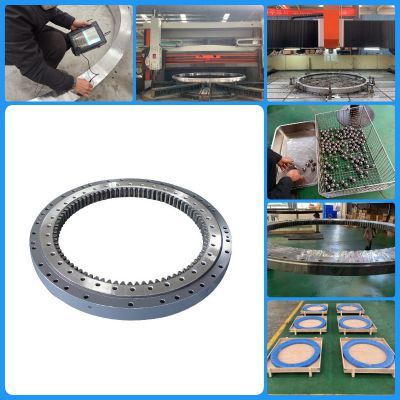

EBL.20.0414.200-1STPN China Precision Slewing Bearing Dia 504*304*56mm

EBL.20.0414.200-1STPN China Precision Slewing Bearing Dia 504*304*56mm

Introduction

External Tooth/Internal Flange Slewing Bearing, also known as LYMC Slewing Bearing, is a critical component used in

various industries due to its unique design and exceptional performance.

This article aims to provide an overview of LYMC Slewing Bearing, highlight its advantages,

and explore its common applications in different industries.

Advantages of External Tooth/Internal Flange Slewing Bearing

1. Enhanced Load Capacity: LYMCSlewing Bearings are specifically designed to handle heavy axial and radial loads,

making them ideal for applications that require exceptional load-carrying capabilities.

The high load capacity ensures optimal efficiency and reliability in diverse operating conditions.

2. Compact Design: LYMCSlewing Bearings offer a compact design, allowing them to be integrated

into space-constrained systems or machinery. Their efficient design maximizes available space while

delivering exceptional rotational performance.

3. Rotational Precision: These slewing bearings are manufactured with high precision, ensuring minimal friction,

smooth rotation, and accurate positioning. This characteristic is essential for applications that require precise

control and movement.

4. Versatility: LYMC Slewing Bearings are versatile and can be customized to meet specific application requirements.

They are available in various sizes, designs, and materials, making them suitable for a wide range of industrial

applications.

Common Applications of External Tooth/Internal Flange Slewing Bearing

1. Construction Machinery: LYMC Slewing Bearings are extensively used in construction machinery, such as cranes,

excavators, and concrete pumps. Their ability to handle heavy loads, combined with their compact design,

makes them essential for safe and efficient operation in construction sites.

2. Wind Energy: These slewing bearings play a vital role in wind turbines. They are used in pitch and yaw systems,

enabling the efficient adjustment of rotor blades to optimize wind energy capture.

The high load capacity and rotational precision of LYMC Slewing Bearings ensure the stability and effectiveness

of wind turbines.

3. Industrial Robotics: LYMC Slewing Bearings are utilized in industrial robotic systems for precise movement,

enabling robots to perform delicate tasks with accuracy and efficiency. Their compact design and rotational

precision contribute to the overall performance and reliability of these systems.

4. Mining Equipment: Proven to withstand harsh operating conditions, LYMC Slewing Bearings are commonly

employed in mining equipment such as tunnel boring machines, stacker reclaimers, and crushers.

They provide reliable support for heavy machinery, ensuring safe and efficient operations in demanding

mining environments.

Conclusion

In summary, External Tooth/Internal Flange Slewing Bearings offer numerous advantages such as enhanced

load capacity, compact design, rotational precision, and versatility. Their applications span across various industries,

including construction machinery, wind energy, industrial robotics, and mining equipment.

The exceptional performance and reliability of LYMC Slewing Bearings make them indispensable components

in versatile applications, contributing to the overall efficiency and safety of various systems and machinery.

Type | • Single row four point contact ball slewing bearing • Single row crossed cylindrical roller slewing bearings • Double row ball slewing bearings •Double row Roller/ball combination slewing bearing •Three-Row Roller Slew Ring Bearing |

| Rolling elements | Steel ball / Cylinder Roller |

| Rolling elements Material | GCr5/GCr15SiMn/Customized |

| Bearing Material | 50Mn/42CrMo/42CrMo4V /Customized |

| Cage Material | Nylon/ steel /copper |

| Structure | taper pin , Mounting holes,Inner ring ,grease fitting,load plug, seals , roller ,spacer balls or separators |

| Outer diameter | 50-10000mm |

| Bore size | 50-10000mm |

| Mounting hole | Through hole/Tapped hole |

| Raceway hardness | 55-62HRC |

| Inner and outer ring modulation hardness | 229-269HB/Customized |

| Gear type | No gear ,Internal gear , External gear. |

| Embellish grease | EP2 lithium lubricating grease |

| Certificate | ABS.BV,DNV,ISO9001,GL,3.1,3.2 |

Application area | Ladle turret,Stacker crane,Bucket wheel machine,Solar heliostat Tracking System,port crane, Cabling machine,tower crane , offshore platform,ferris wheel, Palletizing robot,Rotary metallurgical furnace,can packing machine,Wind blade transporter,shield tunneling machine,tube push bench,excavator |

| Brand Name | LYMC |

| Place of Origin | Luoyang Henan |

| Warranty | 12 months |

| Payment term | T/T is our first choice |

Packing details | 1,Filling with anti-rust oil 2.Corved with Plastic paper 3.Corved with kraft paper 4.Corved with Blue tie 5.Put in wooden box |

Send Inquiry to This Supplier

You May Also Like

-

EBL.20.1094.200-1STPN Slewing Bearing Mixing Spooling Size 1098.4*984*56mmUS$ 200 - 300MOQ: 1 Set

-

EBL.30.0955.200-1STPN Slewing Bearing Marine Cranes 1096*805*90mmUS$ 200 - 300MOQ: 1 Set

-

EBL.30.1055.200-1STPN Slewing Ring Bearing Marine Cranes 1198*905*90mmUS$ 200 - 300MOQ: 1 Set

-

EBL.30.1155.200-1STPN Swing Bearing And Rotary Table Bearing 1298*1005*90mmUS$ 200 - 300MOQ: 1 Set

-

EBL.30.1255.200-1STPN High Performance Material Handling Crane Turntable Bearings Slewing Bearing Swing Ring Size 1398*1105*90mmUS$ 200 - 300MOQ: 1 Set

-

ZBL.20.0414.200-1sptn Excavator Slewing Bearing Slewing Ring Bearing 518*453*56mmUS$ 200 - 300MOQ: 1 Set

-

ZBL.20.0544.200-1sptn Light Load Slewing Bearing Slewing Ring Bearing 648*444*56mmUS$ 200 - 300MOQ: 1 Set

-

ZBL.20.0644.200-1sptn Turntable Slewing Ring Bearings Cylindrical Roller Slewing Bearing 748*546*56mmUS$ 200 - 300MOQ: 1 Set

-

ZBL.20.0844.200-1sptn Turntable Slewing Ring Bearings Cylindrical Roller Slewing Bearing 948*546*56mmUS$ 200 - 300MOQ: 1 Set

-

NBL.20.0414.200-1pptn Toothless Slewing Bearing, Amusement Machinery Turntable Bearing, Excavator Accessories 518*304*56mmUS$ 200 - 300MOQ: 1 Set