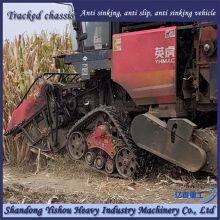

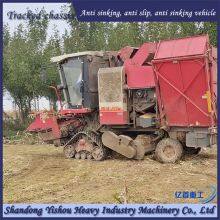

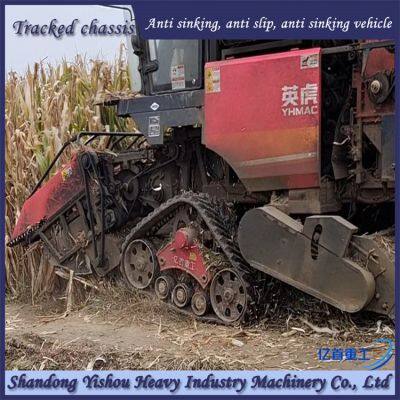

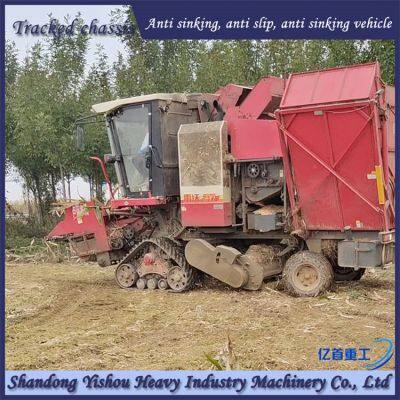

Triangle Track Assembly Harvester Modification Improves Passability

The buffer spring of the triangular track chassis tensioning device has a certain preload, which generates a preload force in the track. Its function is to not affect the meshing between the track pin and the driving gear teeth due to slight external forces when moving forward, and to generate sufficient traction force to ensure the normal meshing between the track pin and the driving gear teeth.

The tension spring, due to the recoil effect of the device, presses against the guide wheel on the right side to maintain a certain tension state during operation, thereby guiding the track tension guide wheel.

The main function is to cooperate with the tensioning device to achieve elastic tensioning of the track. The function of the tensioning device is to achieve the tensioning effect by pushing the guide wheel through the spring. Therefore, compression and tension springs can be selected.

Send Inquiry to This Supplier

You May Also Like

-

Anti Sinking Track Chassis Engineering Machinery Modification Saves LaborUS$ 2800 - 28000MOQ: 1 Pair

-

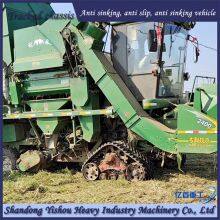

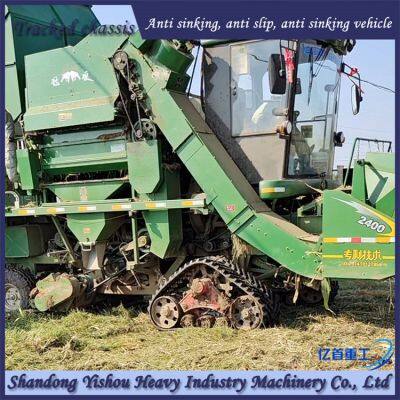

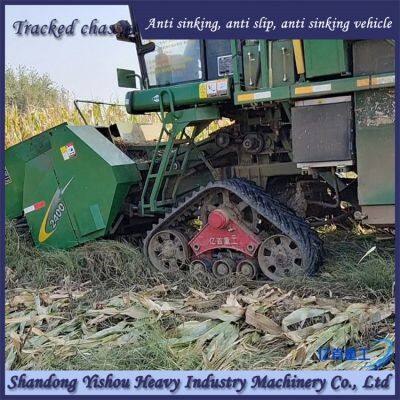

Wheat Harvester Modified Chassis to Prevent Slipping on Muddy GroundUS$ 2800 - 28000MOQ: 1 Pair

-

762 Type Triangular Track Chassis Modification Customized Anti SinkingUS$ 2800 - 28000MOQ: 1 Pair

-

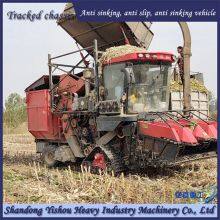

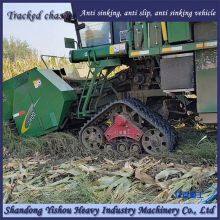

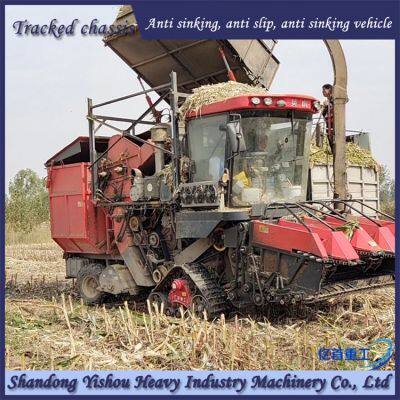

Corn Combine Harvester Modified Track Chassis Anti Sinking VehicleUS$ 2800 - 28000MOQ: 1 Pair

-

635 Type Tracked Chassis Modification With Large Grounding AreaUS$ 2800 - 28000MOQ: 1 Pair

-

Customized Production of 915 Anti Sinking Track ChassisUS$ 2800 - 28000MOQ: 1 Pair

-

Large Vehicle Modification 915 Heavy-duty Track ChassisUS$ 2800 - 28000MOQ: 1 Pair

-

762 Type Triangular Anti Trap Chassis Kesdil Can be ModifiedUS$ 2800 - 28000MOQ: 1 Pair

-

High Horsepower Tractor Modified Track Chassis With Strong Climbing AbilityUS$ 2800 - 28000MOQ: 1 Pair

-

Customized Triangular Anti Sinking Tracks for Loaders to Improve Engineering EfficiencyUS$ 2800 - 28000MOQ: 1 Pair