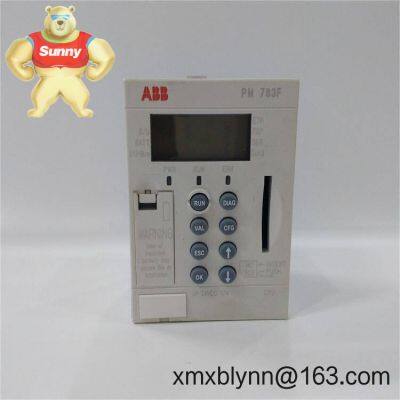

ABB PM783F 3BDH000364R0002 – Controller CPU for Freelance (AC 800F) Systems

Warranty: 365 days

Delivery time: 1 week for in-stock items; no more than 1 month at the latest

Payment: 50% advance payment; full payment before delivery

Express options: FedEx, UPS, DHL

Freelance/AC 800F controller CPU – Designed for ABB’s Freelance DCS, with smooth engineering in Control Builder F.

Fieldbus-focused architecture – In many cases, the PM783F is used with PROFIBUS DP, Modbus TCP/RTU, and FOUNDATION Fieldbus (via linking devices) to cover DI/DO/AI/AO needs.

Stable 24 VDC operation – Industrial 24 VDC supply helps keep panels compact and maintenance simple.

Redundancy-ready design – Supports controller redundancy configurations for higher availability where the process can’t stop.

Integrated diagnostics – You might notice faster fault localization thanks to status LEDs, system logs, and engineering tool diagnostics.

Open communications – Ethernet-based system access and serial connectivity for legacy equipment are typically available.

| Brand / Model | ABB PM783F (3BDH000364R0002) |

| HS Code | 8537.10 – Boards, panels, consoles for electric control (≤1000 V) |

| Power Requirements | 24 VDC nominal (typically 18–30 VDC), ripple per industrial PLC standards |

| Dimensions & Weight | AC 800F CPU form factor for cabinet/base-plate mounting; controller-size footprint (approx. controller module scale) |

| Operating Temperature | Typically 0…+55 °C (non-condensing, per ABB controller practice) |

| Signal I/O Types | No onboard I/O; DI/DO/AI/AO via fieldbus remote I/O (e.g., PROFIBUS DP, FOUNDATION Fieldbus through linking devices, Modbus RTU/TCP) |

| Communication Interfaces | Ethernet 10/100 (RJ45) for engineering/system; serial ports (RS‑232/RS‑485) in many configurations; additional fieldbus via interface modules |

| Installation Method | Control cabinet mounting on base/backplate; DIN rail possible with appropriate accessories; proper grounding/shielding recommended |

The PM783F is commonly deployed in process industries where fieldbus-centric architectures make sense:

Water and wastewater plants modernizing legacy PROFIBUS networks

Oil & gas skids and pipelines needing Modbus TCP/RTU integration

Chemical and pharmaceuticals with distributed FF/DP I/O islands

Metals, mining, and power balance-of-plant where redundancy matters

Pulp & paper and F&B lines requiring quick diagnostics and stable uptime

Reliability – Stable 24 VDC controller with mature firmware; redundancy options for critical services.

Compatibility – Works well with existing fieldbus I/O. You typically won’t have to rip and replace your remote I/O islands.

Lifecycle cost – Simple commissioning and diagnostics reduce engineering hours and site visits over time.

Support – Documentation and service ecosystem for Freelance/AC 800F is widely available, which usually shortens troubleshooting cycles.

A maintenance supervisor told us their team “swapped to PM783F on a shutdown weekend and kept the same DP segments—startup was smoother than expected.” That’s typical when the fieldbus design is already in good shape.

Installation & MaintenancePanel & environment – Install in a ventilated control cabinet. Keep within ambient limits (commonly 0–55 °C) and avoid condensation.

Power & grounding – Use a regulated 24 VDC supply with proper earthing. Separate power and signal wiring; twist and shield fieldbus lines per ABB guidelines.

Network – For redundancy or segmented networks, consider managed industrial switches and ring or star topologies as recommended.

Maintenance – Periodically back up the controller project, check event logs, clean dust from vents, and review firmware release notes before updates.

Spare parts – Keep a spare PM783F and critical interface modules if your process cannot tolerate downtime.

CE compliant; RoHS/REACH conformity is expected for ABB industrial controllers

UL/cUL certifications are common for this product class (check the specific marking on the unit or datasheet)

Manufacturer quality management under ISO standards

Our warranty: 365 days; ABB factory warranty may vary by region and supply route

24 VDC industrial power supply with sufficient headroom and buffering

Managed industrial Ethernet switch (for controller and engineering network)

PROFIBUS DP cabling and terminators; FOUNDATION Fieldbus linking device when FF H1 is needed

Surge protection and proper grounding kits to improve EMC resilience

Note: Interface availability and exact mechanical details can vary slightly by hardware revision. If you share your existing network topology and firmware level, we can cross-check the PM783F build against your system for a neat, low-risk drop-in.

Send Inquiry to This Supplier

You May Also Like

-

UNS0887A-P3BHE008128R0001 New Technology Product Analyze Energy Usage DataNegotiableMOQ: 1 Bag

-

ABB PP835A (3BSE042234R2) Panel 800 HMI – Rugged Operator Interface for Industrial PLC/AC 800M SystemsUS$ 1400MOQ: 1 Unit

-

PM632 Processor Unit Able to Play With Its Powerful Data ProcessingNegotiableMOQ: 1 Bag

-

UNS2882A3BHE003855R0001 Embedded Module Enhanced SecurityNegotiableMOQ: 1 Bag

-

HE700GEN200 Control Interface Module Improve the Response Speed of the Control SystemNegotiableMOQ: 1 Bag

-

ABB PPD113B01-10-100000 – Control Board for ABB Industrial Drive and Automation SystemsUS$ 11000MOQ: 1 Unit

-

FC-9801F Semiconductor Mainframe Computer Advanced Processing CapabilityNegotiableMOQ: 1 Bag

-

3BHE009681R0101 Dc Speed Regulating Thyristor IGCT ModuleNegotiableMOQ: 1 Bag

-

PPD513A0E110110 3BHE039724R0E41| PPD513A | ABB Excitation ControllerUS$ 86000 - 88000MOQ: 1 Combo

-

HC800A CP800A PDP800A Communication Module| System ControllerUS$ 6300 - 6500MOQ: 1 Combo