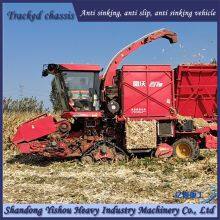

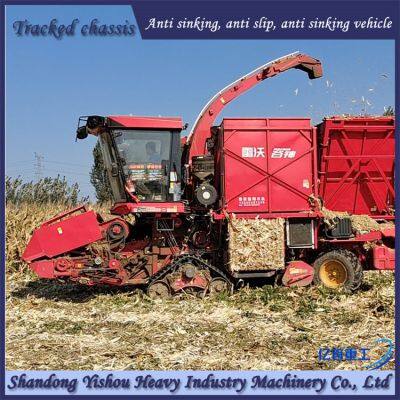

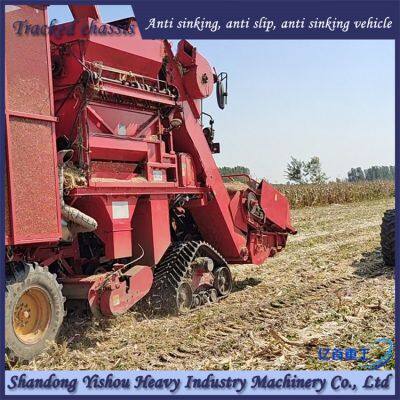

Modification of Rubber Track Chassis for Corn Harvesters to Prevent Derailment

Reduce pressure and extend service life

Due to its larger load-bearing area, the triangular track wheel has a relatively larger grounding area and bears less load pressure, thereby reducing the pressure on the ground, protecting the ground, and extending the service life of the tire.

Improve operational efficiency

The surface of the triangular track wheel adopts an anti slip design, which can maintain good grip in humid, muddy and other environments, thereby improving the operating efficiency of the machine and reducing the time and labor costs during operation.

In summary, triangular track wheels are widely used in industrial and agricultural machinery due to their unique structural design, strong load-bearing capacity, good adaptability, and long service life.

Send Inquiry to This Supplier

You May Also Like

-

Customized Modification of Track Chassis for Wheat Harvesters to Prevent SinkingUS$ 2800 - 28000MOQ: 1 Pair

-

Customized Modification of Various Specifications and Models of Triangular Track WheelsUS$ 2800 - 28000MOQ: 1 Pair

-

Rubber Track Semi Chain Track Anti Slip and Anti SinkingUS$ 2800 - 28000MOQ: 1 Pair

-

Customized Triangular Track Wheel Anti Sinking Vehicle for Wheat Harvesters During Rainy Season HarvestingUS$ 2800 - 28000MOQ: 1 Pair

-

762 Anti Sinking Track Chassis Customized Vehicle Anti SinkingUS$ 2800 - 28000MOQ: 1 Pair

-

Customized Wear-resistant and Durable 635 Track ChassisUS$ 2800 - 28000MOQ: 1 Pair

-

Customized Modification of Tracked Chassis for Trucks With High Load-bearing CapacityUS$ 2800 - 28000MOQ: 1 Pair

-

Customized Rubber Track Chassis for Loaders With Strong Off-road PerformanceUS$ 2800 - 28000MOQ: 1 Pair

-

Customized Anti Sinking Track Chassis for Wheat Combine HarvestersUS$ 2800 - 28000MOQ: 1 Pair

-

Customized Triangular Track Semi Chain Track Corn Harvester Not Afraid of Rainy SeasonUS$ 2800 - 28000MOQ: 1 Pair