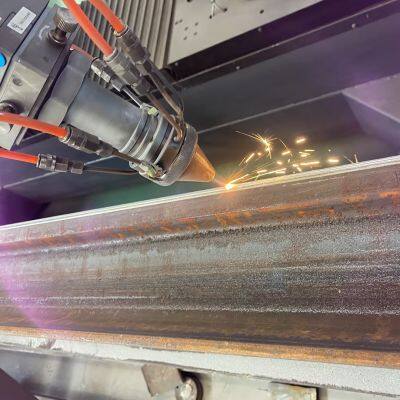

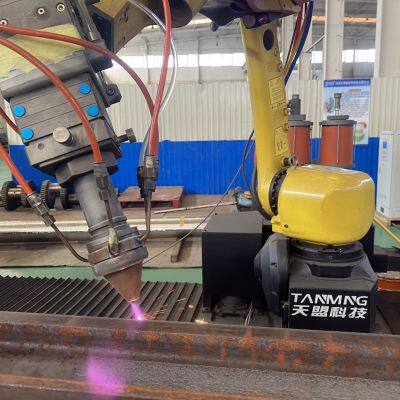

Laser Cladding Surface Repair for Corrosion Prevention and Wear Resistance

Send Inquiry to This Supplier

You May Also Like

-

Tianmeng Supersonic Spray Processing is Suitable for the Mechanical Industry, With Adjustable Coating HardnessNegotiableMOQ: 1 Square Meter

-

Tianmeng Thermal Spray Laser Cladding Processing Shell Surface Strengthening Treatment Extends Service LifeNegotiableMOQ: 1 Square Meter

-

Surface Spraying Repair of Workpiece by Supersonic Arc Spraying+plasma Processing Anti-corrosion and Wear-resistant NiA1955NegotiableMOQ: 1 Square Meter

-

Surface Repair of Tianmeng Raft by Plasma Spraying, Nickel Aluminum Coating, Anti-corrosion and Wear-resistant Coating, Thermal Spraying ProcessingNegotiableMOQ: 1 Square Meter

-

Surface Repair of Raft by Plasma Spraying With Nickel Aluminum Coating, Anti-corrosion and Wear-resistant Coating, Thermal Spraying ProcessingNegotiableMOQ: 1 Square Meter

-

Preparation of Durable Nickel Luo Alloy Coating by Heavenly Alliance Supersonic Arc SprayingNegotiableMOQ: 1 Square Meter

-

Professional Processing of Wear-resistant, Anti-corrosion, and High-efficiency Spray Coating Technology for Laser Cladding Fan ShaftNegotiableMOQ: 1 Square Meter

-

Stretch Roller Spray Enhanced Teflon Coating for High Bonding Strength, Non-stick and DurableNegotiableMOQ: 1 Square Meter

-

Thermal Spraying Arc Spraying Process Guide Roller Surface Repair to Increase Anti-corrosion and Wear-resistant PreparationNegotiableMOQ: 10000 Square Meters

-

Preparation of Anticorrosive and High Temperature Resistant Coating by Supersonic Spraying Enhanced Tungsten Carbide CoatingNegotiableMOQ: 10000 Square Meters