High Density Calcium Silicate Board, Carbon Fiber, Glass Fiber

High density non stick calcium aluminosilicate board is a non asbestos refractory material with high strength, low shrinkage rate, and low thermal conductivity. It mainly has two types: glass fiber reinforcement and carbon fiber reinforcement. The volume density is generally 800-1000kg/m, and the maximum operating temperature is 1000 ° C. Norse adopts a unique fiber dispersion technology to evenly distribute fibers in the calcium silicate matrix, greatly improving the high temperature resistance and thermal shock resistance of the board.

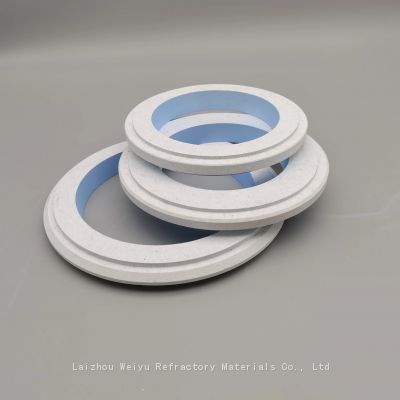

High density non stick calcium aluminosilicate board has good thermal shock stability, excellent mechanical processing performance, and non stick aluminum, which can be easily processed into various precision components. It is mainly suitable for the non-ferrous metallurgical industry, especially LPDC, HPDC, CPC, and gravity casting related equipment, such as hot top rings, adapter plates, cover plates, gates, nozzles, casting boxes, flow channels, casings, etc.

High density calcium silicate insulation board

The density range of high-density calcium silicate insulation board is 750-900kgs/cbm, which is developed for the non-ferrous metal industry and used for feeding, casting, and forming of aluminum and other non-ferrous metals. High density calcium silicate insulation board can also be used as fixtures in the glass industry. In addition to insulation, its non stick aluminum properties are also significant. Superior strength and excellent processing ability make it the preferred material for precision CNC machining of parts and complex components

HS code 6806900000

How can I get your timely quotation?

If you can send us the factors such as working temperature, bulk density, size (length * width * thickness), and quantity, we can reply to your quotation soon.

What are the requirements of the command?

No restrictions, we can provide the best suggestions and solutions based on your situation.

3. What payment terms can you accept?

We provide telephone/telephone, LCD, Western Union telephone.

When will delivery be made after placing the order?

Confirm the order 15-25 days later.

5. Does your company accept customization?

We accept OEM services.

How to solve quality problems?

If the product does not meet the customer's sample requirements or has quality issues, our company will be responsible for this.

7. What is coordination system code?

The coordination system code is 68099000

1. Timely response,

Timely reply to your inquiries, provide multiple options and suggestions based on your needs, quickly reply to emails and provide solutions.

2. Sampling evaluation

Accept samples and trial orders for quality evaluation

3. Strict quality control

Arrange production on time and strictly control quality

4. Shorten delivery time.

Book the earliest vessel or aircraft to ensure delivery time

5. Professional services

Provide all detailed news and images from delivery to delivery;

If necessary, provide relevant export documents and original documents;

Warm and considerable after-sales service company information WY refractory material export company is one of the most professional refractory material suppliers in China, with main products including refractory materials, insulation materials, heating elements, industrial ceramics, etc. Frequently asked questions

APPLICATIONS AND INSTALLATION

Cement industry、Nonferrous、Petrochemical、Power plant、Glass industry、Ceramic industry etc.

(PACKING,TRANSPORTATION,STORAGE AND SAFTY):

General packing is paper-board carton ande polybag inside avoiding moisture.

Rain proof and moisture proof during transportation ,handled with care.

Storage areas should be flat and drying.

Protective clothing, dust mask and glovers for site operation.

CHEMICAL ANALYSIS:

SIO2……………………………………………………49-52%

CaO……………………………………………………39-42%

AlO3……………………………………………………0.4-0.5%

MgO……………………………………………………0.5-0.7%

Fe2O3……………………………………………………0.3-0.4%

Na2O-K2O……………………………………………… 0.9-0.1%

Lgnition loss(mainly H2O) ………………5-9%

Send Inquiry to This Supplier

You May Also Like

-

Shandong Laizhou Calcium Silicate Fireproof BoardUS$ 190 - 550$MOQ: 10 Cubic Meters

-

Hot Selling Calcium Silicate Board Manufacturer in LaizhouUS$ 10 - 1000MOQ: 1 Cubic Meter

-

Qingdao Calcium Silicate Board 1000mm * 500 * 50US$ 120 - 550MOQ: 1 Cubic Meter

-

Shandong Laizhou Calcium Silicate Asbestos Free Calcium Silicate BoardNegotiableMOQ: 1 Cubic Meter

-

Shandong Calcium Silicate Fireproof BoardUS$ 120 - 900MOQ: 20 Cubic Meters

-

Asbestos Free High-temperature Resistant Calcium Silicate Board Laizhou Refractory BoardUS$ 90 - 120MOQ: 20 Cubic Meters

-

1050 ° Calcium Silicate Furnace SmeltingUS$ 150$ - 320$MOQ: 50 Cubic Meters

-

Asbestos Free Calcium Silicate Board for Insulation 30US$ 190 - 450MOQ: 50 Cubic Meters

-

Asbestos Free Calcium Silicate High-temperature Insulation BoardUS$ 150$ - 320$MOQ: 50 Cubic Meters

-

High Temperature Silicon Refractory Board Insulation Calcium Silicate BoardUS$ 190$ - 320MOQ: 50 Cubic Meters