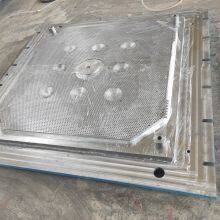

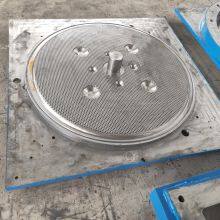

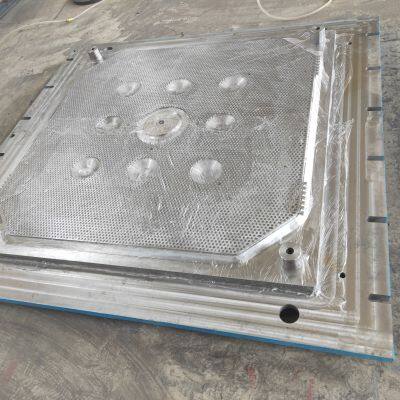

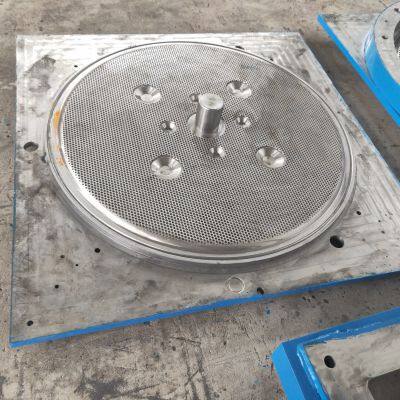

Plastic PP Membrane Hot Chamber Vertical Frame Membrane Filter Press Plate Mold

Plastic PP Membrane Hot Chamber Filter Press vertical Frame Filter Plate welding machine plate-and-frame belt

Filter plates adopt pp material to press mould, and the design of filtration surface adopts special channel, smooth and without any blockage. Material of JINGJIN plate consists of TPE elastomer, fiber glass, and Polypropylene. So our plates have the advantage of flexibility, toughness, rigidity. After the process of the CNC machining center, the flatness of the filter plate is lower than 25µm which make sure excellent sealing when pressing, and without any leakage when feeding.

All specifications of our plates not only comply with China JB/T4333.3-2005 standard, but also comply with Germany DIN7129 standard, completely in common with the European& American products.

Compared with the filtration plates manufactured according to national standards: filtration speed improved 20%, density and intensity, anti-fatigue, anti-aging speed improved one times

The maximum feeding pressure of the filter plate is 1.6Mpa. With the properties of high temperature and high pressure resistance, antisepsis and airtight, short filtering cycle, good processing effect and low humidity of the cake.

Main detailed machine parts of the pp hollow sheet extrusion line

Extruder: special venting type design, advanced PLC temperature control system to ensure that

plastic sound and high-yield stability in plastics extrusion.

Screen Changer: optional hydraulic quick changer device, so that the process of changing network

quickly and efficiently; duplex and special sealing structure, and ensuring stability for network

devices.

Mould: mould made of high-quality alloy steel with high activity of the throttling device, so the distribution

of material flow in the die pressure is uniform; the upper and lower lips of die is of differential

regulation, ensures a uniform thickness from top to bottom.

Vacuum forming stand: forming system with a fast heat exchange cooling system, and with vacuum

system, an effective staggered, sequential distribution to guarantee the accuracy of the sheet's

shape. Vacuum system consists of two independent sub-structure, each subsystem equipped

with a fixed number of three-loop vacuum lines, each carrying a fixed cycle of both the

vacuum-conditioning system and vacuum display system, thus making the surface of vacuum

plate uniform and stable .

Send Inquiry to This Supplier

You May Also Like

-

Stainless Steel Beam Filter Press Price,plate-frame Structure Dehydration Filter MachineUS$ 10000 - 100000MOQ: 1 Set

-

Green House Plastic Polypropylene Ppr Capillary Tube Mat for Heating and MachineNegotiableMOQ: 1 Piece

-

Huitai Plastic Polypropylene Ppr Capillary Tube Mat for Heating and MachineNegotiableMOQ: 1 Piece

-

Huitai Bestcome Plastic Polypropylene Ppr Capillary Tube Mat for Heating and MachineNegotiableMOQ: 1 Piece

-

Huitai Bestcome Plastic Polypropylene Ppr pp Capillary Tube Mat for Heating and MachineNegotiableMOQ: 1 Piece

-

Huitai Bestcome Plastic Polypropylene Ppr pp Capillary Tube Mat for Heating and MachineNegotiableMOQ: 1 Piece

-

Oem Huitai Bestcome Plastic Polypropylene Ppr pp Capillary Tube Mat for Heating and MachineNegotiableMOQ: 1 Piece

-

Huitai Bestcome Plastic Polypropylene Ppr Capillary Tube Mat for Heating and Machine AutomaticNegotiableMOQ: 1 Piece

-

Plastic Polypropylene Ppr pp Capillary Tube Mat for Heating and Machine EquipmentNegotiableMOQ: 1 Piece

-

UHMWPE Sheet Plate Board Ultra High Molecular Weight Polyethylene Sheet With High Impact ResistanceNegotiableMOQ: 2 Pieces