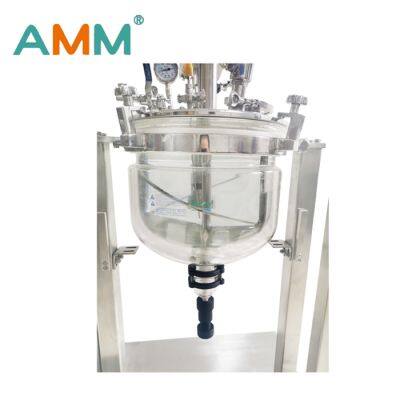

AMM-50S Laboratory Elevatable Mixing Emulsification Reactor for Foundation Make-up Essence Homogenization in Cosmetics Industry

Application

The processing capacity of the AMM standard system is 0.5L, 1L, 2L, 5L, 10L and other model. It can realize the process of material dispersion, emulsification, homogenization, and mixing under vacuum or pressure environment. It can be equipped with a variety of high-efficiency macro mixers (optional), high-shear homogeneous emulsifier (optional), and reliable vacuum sealing system and temperature control system. A variety of sensor detection systems can simulate industrial production in a laboratory environment. It is a good choice for conventional complete laboratory equipment and meets all simulation conditions of complete equipment

Features

Benchtop modular jacketed vacuum emulsifier glass reactor hydrogenation solutions

The equipment is highly modular and can be equipped with various functional systems. High speed motor imported from Germany, long life design, stable operation. Lightweight design of the entire system, integrating a small lifting system. Stepless speed regulation, the maximum speed can reach 30,000rpm, and the maximum cutting line speed is 27m / s for you. Meet your different working environment (closed, open, normal pressure, vacuum, gas protection, high temperature, low temperature) The working head is made of stainless steel, which can be reused and meets hygienic standards. Modular design of equipment, any system can be flexibly combined. Add any other custom

Power 220V/50Hz |

Stirring volume 8L |

volume 20L |

Emulsification volume 10L |

Max working temp 120 ° (optional high temperature) |

Heating method water bath, oil bath circulation |

Vacuum condition -0.096Mpa (positive pressure optional) |

Viscosity max. 130000CP |

Mixer power 750W |

Mixer speed 13~86rpm /130~2000rpm (high speed optional) |

Mixer agitator Anchor scraper (optional spiral belt) |

Scraper material Silicone rubber (optional PTFE hard scraper) |

Homogenizer power 750W |

Homogenizer speed 300-6000rpm |

Speed display LCD display (digital display timing) |

Homogenizer head model 60BCS |

Openings on cover Homogenizer opening, hopper opening, temp measurement opening, vacuum opening,3 spare opening |

Bracket lifting method Electric auto lift (semi-auto cylinder lifting optional) |

Lifting height 430mm |

Medium-contact material SUS316L stainless steel PTEF borosilicate glass |

Reactor body material borosilicate glass (SUS316L stainless steel container is optional) |

Outer Dia. vacuum opening 10mm |

Jacket inlet/outlet size 12mm |

Wooden Dimensions Reference Design Drawing |

Weight Reference Design Drawing |

Send Inquiry to This Supplier

You May Also Like

-

AMM-SE-10L Semi Automatic Lifting Closed Reaction Tank - Modular Design With Added Functionality for Mixing and Emulsifying MachineUS$ 15000 - 18000MOQ: 1 Set

-

AMM-SE-5L A Reaction Kettle Capable of Discharging or Flipping Materials for Mixing and Homogenizing Electronic Slurry in the New Energy IndustryUS$ 10000 - 10230MOQ: 1 Set

-

AMM-SE-2L Vacuum Reaction Kettle for Mixing and Homogenizing Cosmetics Essence Liquid and CreamUS$ 7000 - 7380MOQ: 1 Set

-

AMM-1S Laboratory Vacuum Stirring Emulsifier - Reaction Kettle for Research and Development of High Viscosity Resin MixingUS$ 8000 - 8800MOQ: 1 Set

-

AMM-2S Laboratory Vacuum Stirring Emulsifier - Reaction Kettle for Research and Development of High Viscosity Resin MixingUS$ 10000 - 10230MOQ: 1 Set

-

AMM-2S Shanghai Laboratory Ultrasonic Reactor - Closed Emulsification Shear Machine for Nanomaterial DispersionUS$ 10000 - 10230MOQ: 1 Set

-

AMM-2S Shanghai Laboratory Vacuum Emulsification Mixer - Commonly Used Suspension Mixing Shear Machine in the Pharmaceutical IndustryUS$ 10000 - 10230MOQ: 1 Set

-

AMM-5S Laboratory Constant Temperature Stirring Emulsifier - a Sealed Reaction Kettle With Precise Temperature ControlUS$ 10500 - 10950MOQ: 1 Set

-

AMM-5S Sealed Reaction Kettle With Scraping and Stirring in the Laboratory - for Mixing and Stirring Food AdditivesUS$ 10500 - 10950MOQ: 1 Set

-

AMM-10S The Commonly Used Electric Lifting Reaction Kettle in the Laboratory - Stainless Steel Stirring EmulsifierUS$ 15860 - 19860MOQ: 1 Set