Chinese Factory Ginger Juice Production Line At Good Price

Chinese factory ginger juice production line At Good Price

Product details

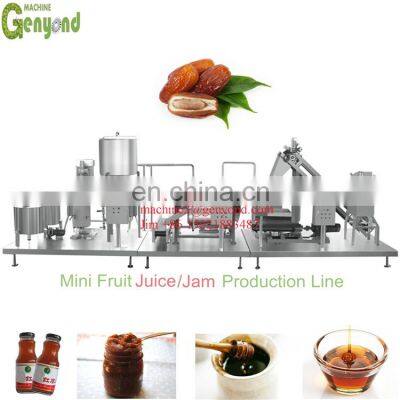

| Name | fruit juice production line |

| Process capacity | 50kg ~500,000kg Per hour |

| Application | apple ,pear,date,orange,tomato,orange,berrys etc. |

| Product Keywords | ginger juice production line |

Specifications of fruit juice production line/fruit juice complete process plant

1.Fruit juice complete production line

2.High quality machines with PLC control system

3.Good after sales service

4.ISO9001

Production process of fruit juice production line/fruit juice complete process plant:

I: choice of raw materials

Choose fully ripe, fresh, good flavor and rich in juice, no plant diseases and insect pests of TaoGuo, maturity insufficient TaoGuo should pass after cooked.

II: the raw material pretreatment

1.clean.Raw materials are chosen after clean with clear water wash and brush to MAO net in 1% hydrochloric acid solution or detergent solution again after rinsing, remove residues of pesticides, and then rinse in clean water, drain well.

2.cut a half to go nuclear.Dig nuclear machine cut in half.

3.soak protect color.Cut after the dig nuclear material in 0.1%.A mixture of ascorbic acid and citric acid solution soak protect color.

III:heating beating

Fruit piece under 90°C to 95 °C, the heat for 3 to 5 minutes, to soften, beating through the pore size of 0.5 mm beater, remove the skin.

IV: flavor adjustment

After dealing with the crust of fruit pulp in order to increase the flavor to be adjusted.Adjust add sugar, citric acid and L - ascorbic acid and other ingredients.Its ratio of peach pulp 100 kg, 80 kg 27% sugar solution, citric acid, L - ascorbic acid 0.07 0.45 kg - 0.2 kg.

V: the homogeneous degassing

Homogeneous is to make juice pulp particles suspended split into smaller particles and uniformly dispersed in the fruit juice, increase the stability of fruit juice, prevent stratification.

1.Homogeneous method is to coarse filter juice by high pressure homogenizer, make juice in the pulp particles and colloid material at high pressure through the 0.002 0.003 mm in diameter of holes and become more fine particles.Commonly used on production of 130-160 kg/cm2 homogenizer.It also can be used for homogeneous colloid mill.When the juice through the colloid mill gap of 0.05 0.075 mm slit, in fruit pulp granules by strong centrifugal force function and mutual impact friction, thereby achieve homogeneous.When the fruit juice into the oxygen, nitrogen and carbon dioxide and other gases, among them, the nitrogen can cause vitamin C and pigment substances such as oxidation and corrosion of tinplate cans, therefore, must be degassing, degassing method basically has the following two kinds:1, vacuum method.The juice into the vacuum container make juice in micro mist jet and degassing.Taken by vacuum method of vacuum degree is 685-711 mm hg or above, temperature is below 43 °C.

2.nitrogen exchange method.Juice from a vertical glass tube or stainless steel tube cone top into nitrogen pressure into the from the bottom.Nitrogen after joining the small bubbles formed in the fruit juice, replaced the oxygen in the fruit juice and achieve the goal of degassing.

VI: sterilization tank

Juice is heated to 95 °C. Lasts 1 min, strike can immediately.

VII: sealed cooling

Screw the bottle cap, the tank inverted for one minute.Immediately after the seal segmented cooling to 38 °C or so, and then warehouse storage.Quality qualified fruit tea products are pink or yellow-brown, allowed dark red;SAP uniform opacity, after long-term rest particles precipitate;With peach juice flavor, without peculiar smell;Soluble solids was 10% - 14%

Send Inquiry to This Supplier

You May Also Like

-

Chinese Factory Equipment for the Production of Carrot Juice With Cheap PricesNegotiableMOQ: 1

-

Factory Made Lemon Juice Processing Plant Best PriceNegotiableMOQ: 1

-

Factory Direct Supplier Citrus Juice Processing Line Best PriceNegotiableMOQ: 1

-

Industrial Cold Press Belt Orange Juicer MachineNegotiableMOQ: 1

-

Dried Mango Chips Processing MachineNegotiableMOQ: 1

-

Dry Mango Powder Making MachineNegotiableMOQ: 1

-

Mango Hot Water Treatment PlantNegotiableMOQ: 1

-

Raw Mango Cutting MachineNegotiableMOQ: 1

-

Small Mango Processing MachineNegotiableMOQ: 1

-

Hawthorn Making Machine Fruit Danpi Leather MachineNegotiableMOQ: 1