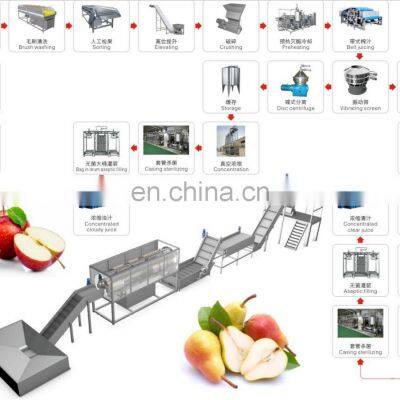

Industrial Fruit Large Vegetable Juice Making Machine Juicer Production Line

Canned food is a kind of food that can store for a long time after pre-processing,seasoning, filling,vacuum sealing,sterilizing.After many years’ devotion to canned fruit processing line,our company has developed advanced and mature canned fruit processing design and turnkey project.We are aimed at providing the most reasonable processing equipment for customers. The complete canned fruit production line includes pre-processing,filling,exhausting, sealing, sterilizing,cooling cedures.

The first part:

Lifting system, cleaning system, sorting system, crushing system, preheating and inactivating enzyme system, beating system,vacuum concentration system, sterilization system, aseptic big bag filling system

The Second part:

Extraction pump → preparation tank → homogenization → degassing → sterilization machine → can washing machine (bottle) machine →filling machine → capping machine (capping machine) → tunnel spray sterilization machine → drying machine → Inkjet Printer →Packing

Extra process for pineapple juice

|

|

|

|

| Liquid product form : Fruit juice jam processing, fruit wine vinegar enzyme processing, plant extract processing production lines can be roughly divided into the following process sections * Cleaning and picking process section: mainly includes raw material receiving, cleaning, sorting, etc. * Crushing and beating process section: mainly includes crushing of raw materials, enzyme inactivation, beating, etc. * Biochemical refining process section: mainly includes enzymatic hydrolysis, fermentation, filtration, blending, degassing, homogenization, etc. * Sterilization and filling process section: mainly includes UHT sterilization, filling, post-pasteurization, etc.; |

|

| Solid product form Dried fruit processing and fruit powder processing production lines can be roughly divided into the following process sections * Cleaning and picking process section: mainly includes raw material receiving, cleaning, sorting, etc. * Peeling and slicing process section: mainly including stem removal, stem removal, skin removal, core removal, slicing, etc. * Biochemical refining process section: mainly includes blanching, color protection, sugar soaking, drying, etc. * Spray drying powder process: liquid product form - sterilization filling process section - sterilization - spray drying -secondary drying / granulation, etc. |

|

|

|

Send Inquiry to This Supplier

You May Also Like

-

Automatic Pure Water Mineral Water Plastic Bottle Washing Filling Capping Producing Machine Liquid Filling LineNegotiableMOQ: 1

-

Automatic Pure Water Mineral Water Plastic Bottle Washing Filling Capping Producing Machine Liquid Filling LineNegotiableMOQ: 1

-

Fully Automatic Stainless Steel Hot Fruit Plastic Bottle PET Bottle Mango Juice Beverages Drinks Filling Machine Production LineNegotiableMOQ: 1

-

Reliable and Cheap Coconut Cutting Half Machine Cutter With ISO9001 CertificatesNegotiableMOQ: 1

-

GYC 300~2000pcs/h Tender Young Green Coconut Water Juice Extractor Extraction Cut Cutting Half Opener MachineNegotiableMOQ: 1

-

GYC Diamond Shaped Green Young Coconut Cutting Half Cut Opening Opener MachineNegotiableMOQ: 1

-

Genyond Automatic Ice Pop Making MachineNegotiableMOQ: 1

-

1 Ton per Hour Plastic Tube Ice Pop Making MachineNegotiableMOQ: 1

-

GYC Small Ice Lolly Pop Filling and Sealing MachineNegotiableMOQ: 1

-

China Ice Lolly Popsicle Making MachineNegotiableMOQ: 1