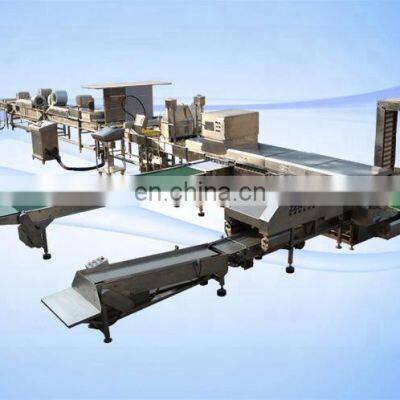

Waste Paper Recycle Used Egg Tray Machine/automatic Paper Pulp Egg Tray Production Line/small Machine Making Egg Tray

1. pulping system :

Put the waster paper in to the hydrapulper, the paper and water will mix in hydrapulper ,then go to the refiner machine, refiner machine make the pulp more small egg tray moulding machine/egg tray production line

and uniform, then the pulp pump absorb the pulp to the pulp pool. after the second mix in the pulp pool, the pulp will go to the form machine pulp tank.

The vacuum pump will give the vacuum to make the forming mould absorb the pulp from the pulp tank.there is a PLC control the pulp absorb time,the finished egg tray moulding machine/egg tray production line

product will be shaped on the forming mould, then the transfer mould transfer the products to the drying line, the air compressor will give the air to blow the products, then egg tray moulding machine/egg tray production line

the products will be fall from the mould. the products delivery to the drying line automatic. the water will be go back to the

water pool. will be recycle

There are burners and blowers on the drying line. burner give the hot power and the blower increase it, there will be hot air

mouth in the drying line also blow the hot air. the drying line is protect by the insulation board. the degree can reach 200 degree.

After drying line, the egg trays go to the automatic counting and stacking system, you can preset the quantity of one pile, such as 100pcs or 200pcs.egg tray moulding machine/egg tray production line when the quantity ok, will be alarm. the products stacked at the same time. you can packaged them directly.

Machine Model | GY-3*1 | GY-4*1 | GY-3*4 | GY-4*4 | GY-4*8 | GY-5*8 | GY-5*12 |

Capacity (pcs/h) | 1000 | 1500 | 2000 | 2500 | 3000 | 5000 | 6000 |

Total Power (KW) | 32 | 45 | 58 | 78 | 80 | 85 | 90 |

Paper Consumption (kg/h) | 120 | 160 | 200 | 280 | 320 | 400 | 480 |

Water Consumption (kg/h) | 300 | 380 | 450 | 560 | 650 | 750 | 900 |

Workshop Area (sq.m.) | 45 | 45 | 80 | 80 | 100 | 100 | 120 |

Shanghai Genyond Technology Co Ltd; Zhangjiagang Genyond Machinery Co Ltd

Shanghai Jou Yu industrial Co Ltd; Shanghai Keyfood Machinery Co Ltd

Sino topone machinery; Nantong Yihai Machinery; Kunshan Kpack Machinery

Our products have been exported to more than 160 countries with Annual sales reaching 80 millions in 2022 and it raises by yearly average 10% above.

You just need to give us your idea on final product to be made, processing capacity, way of packing, we will make the proposals for your checking. You can also give us your budget, we can also design a line to meet your budget accordingly. A satisfying project will be given; A long-term cooperation will come.

Send Inquiry to This Supplier

You May Also Like

-

Small Scale Ice Cream Cup and Cone Filling MachineNegotiableMOQ: 1

-

Shanghai Filling Machine for Cone Ice CreamNegotiableMOQ: 1

-

High Efficiency Customized Paper Cup Ice Cream Making Line /machineNegotiableMOQ: 1

-

5000-6000 P/h PE Soft Plastic Tubes Ice Lolly or Ice Pop or Popsicle Yogurt Filling and Sealing Packing Packaging MachineNegotiableMOQ: 1

-

Granule Packaging Machine/food Packaging Machine/snack Packaging MachineNegotiableMOQ: 1

-

China Snack Weight Packing MachineNegotiableMOQ: 1

-

Water Sachet Packaging Machine Juice Water Milk Liquid Pouch Packing Machine Milk Bagging MachineNegotiableMOQ: 1

-

Fully Automatic Packing Machine Wrapping in Square or RoundNegotiableMOQ: 1

-

Hot Filling Tea Beverage Production LineNegotiableMOQ: 1

-

Automatic Milk Tea Cups Filling and Sealing Machine/lineNegotiableMOQ: 1