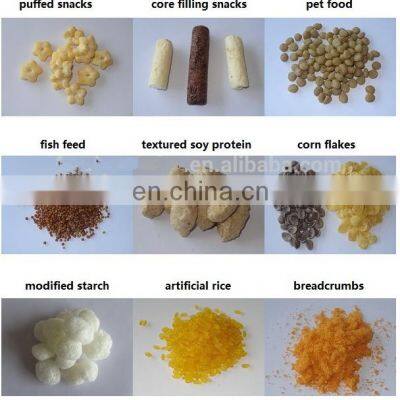

Automatic Healthy Breakfast Corn Flakes Production Line/corn Chips Processing Line

Producion Introduction

Breakfast cereal corn flakes is a brittle food with good rehydration, outside the red is not bad, taste lubricants,grain flavor is fragrant.Corn flakes mainly corn flour as the main raw material,added sugar, vitamins,mixed raw minerals, add a sufficient amount of water after kneading, aging, forming, baking and tableting in order to manufacture a sheet flavoring.

Machine Flow Chart

Mixing system---Extrusion system----Cooling system—Flaking system--Drying system—Toasted system---Sugar Spraying system ---Drying system---- Packing system

Machine Features

1.Mixer : Make the corn residue or corn flour added to a nutritional additive and mixing a proportion of water uniformly.

2.Screw conveyor : Marinated raw material fed to the extruder feed hopper.

3.Double screw extruder: The material in the feed hopper into the extrusion system, to produce small spherical particles.

4.Shaker:Dispersed particles, to avoid overlap pressed together into a tableting machine.

5.Air conveyor:Transported the particles into the tableting machine.

6. Flaking machine:Flaking the corn ball to raw corn flakes.

7.Air conveyor:Transfer the corn flakes to the baking oven.

8.Mutil-layer oven: Oven mostly is toaster,temperature between 0-200 degrees self-regulation through the control cabinet,internal stainless steel double mesh bag,baking time may be adjusted according to the speed,remove the water.

Main Technica Patameters

| Model | GY171-A | GY171-B | GY171-C |

| Installed power | 130kw | 150kw | 180kw |

| Real power | 80kw | 110kw | 140kw |

| Capacity | 100-120kg/h | 200-240kg/h | 300-500kg/h |

| Dimension | 38000*1200*2200mm | 41000*1500*2200mm | 43000*3500*4300mm |

More Pictures

GENYOND MACHINERY INDUSTRIAL GROUP

It has 6 factories in China for food machine and packing machine.

Shanghai Genyond Technology Co Ltd; Zhangjiagang Genyond Machinery Co Ltd

Shanghai Jou Yu industrial Co Ltd; Shanghai Keyfood Machinery Co Ltd

Sino topone machinery; Nantong Yihai Machinery; Kunshan Kpack Machinery

Our products have been exported to more than 160 countries with Annual sales reaching 80 millions in 2022 and it raises by yearly average 10% above.

Genyond machine has more than 100 engineers for the installation of oversea projects.

You just need to give us your idea on final product to be made, processing capacity, way of packing, we will make the proposals for your checking. You can also give us your budget, we can also design a line to meet your budget accordingly.

A satisfying project will be given; A long-term cooperation will come.

Send Inquiry to This Supplier

You May Also Like

-

China Plantain Chips Making MachineNegotiableMOQ: 1

-

Automatic Potato Chips Making Machines With CE/electric Spiral Potato Chips Machine/industrial Potato Chips Making MachineNegotiableMOQ: 1

-

Complete Automatic Potato Chips Making MachineNegotiableMOQ: 1

-

Complete Pumpkin Chips Processing PlantNegotiableMOQ: 1

-

High Efficiency Potato Chips Processing Plant/fried Potato Chips LineNegotiableMOQ: 1

-

Flavored Potato Chips / Sticks Processing Machine / Fried Potato Snack Production LineNegotiableMOQ: 1

-

Industrial Potato Snacks Processing Machine / Potato Chips and Sticks Production LineNegotiableMOQ: 1

-

Complete Crispy Coconut Chips Production LineNegotiableMOQ: 1

-

Desiccated Coconut Drying Machine / Coconut Chips DryerNegotiableMOQ: 1

-

Automatic Potato Chips Production Line/making MachineNegotiableMOQ: 1