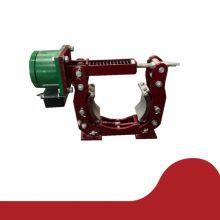

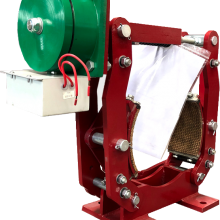

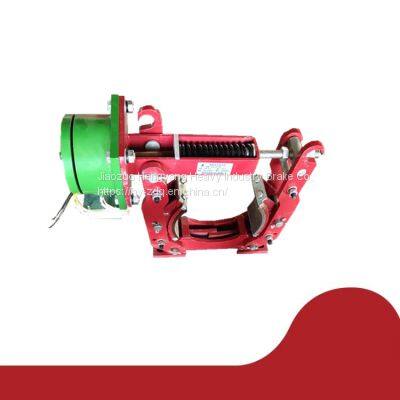

Hengyang Heavy Industry Electromagnetic Drum Brake MW800-10000 Green and Environmental Protection

Capacitor C is continuously charged, and an increasing peak voltage is established at both ends of the capacitor, also known as both ends of the coil, until it exceeds the breakdown voltage of the contact gap that is being disconnected. The contact gap is then broken again, and the previously charged capacitor C is then charged in the opposite direction to the DC bus through an arc. As the contact gap continues to increase, the arc is broken again and the above charging and discharging process is repeated again. The discharge voltage gradually increases, and the voltage of capacitor C can reach tens of thousands of volts. Its Pulsed power is enough to damage semiconductor devices, and because it contains rich harmonic components, it will interfere with the control system and cause misoperation. The external environment is also an important factor in the failure of electromagnetic brakes. For inductive coils, the selection of insulation materials and the prevention of short circuits are crucial, as short circuits are usually the result of insulation damage. The insulation life test of the inductance coil of mechanical equipment shows that vibration has little effect on the life of the electromagnetic brake, and humidity is not the main influencing factor (humidity will slowly change the resistivity between windings, thereby shortening the life of the electromagnetic brake), while thermal cycling is the main reason for reducing the expected life value.

Send Inquiry to This Supplier

You May Also Like

-

Hengyang Heavy Industry MWZ500-2500 DC Electromagnetic Drum Brake With Lifting HookCNY 1500 - 4000MOQ: 5 Units

-

Hengyang Heavy Industry MWZ630-5000 DC Electromagnetic Drum Brake Energy Saving and Stable BrakingCNY 1500 - 4000MOQ: 5 Units

-

Hengyang Heavy Industry MWZ710-8000 DC Electromagnetic Drum Brake Asbestos Free LinerCNY 1500 - 4000MOQ: 5 Units

-

Hengyang Heavy Industry MWZ800-10000 DC Electromagnetic Drum Brake is Safe and Reliable to UseCNY 1500 - 4000MOQ: 5 Units

-

Hengyang Heavy Industry MWZ160-80 DC Electromagnetic Drum Brake Green and Environmental ProtectionCNY 1500 - 4000MOQ: 5 Units

-

MWZ200-160 DC Electromagnetic Drum Brake Sold in Bulk by Hengyang Heavy Industry's Original Manufacturer in StockCNY 1500 - 4000MOQ: 5 Units

-

MWZ250-315 DC Electromagnetic Drum Brake Hengyang Heavy Industry Has an Explosion-proof CertificateCNY 1500 - 4000MOQ: 5 Units

-

MWZ315-630 DC Electromagnetic Drum Brake Hengyang Heavy Industry Has CCC CertificateCNY 1500 - 4000MOQ: 5 Units

-

MWZ400-1250 DC Electromagnetic Drum Brake Hengyang Heavy Industry is Suitable for Industries Such as Port MetallurgyCNY 1500 - 4000MOQ: 5 Units

-

MWZ500-2500 DC Electromagnetic Drum Brake, Safe and Reliable to Use by Hengyang Heavy IndustryCNY 1500 - 4000MOQ: 5 Units