Solar Frame Solar Panel Structure Roll Forming Machine

Welcome to Taicang Global Machinery Co., Ltd

At Global Machinery, we provide Tube Mill, Roll Forming Machine, Slitting & Cut to length Line and corresponding components, and meet your customized requirements. Contact us right now!

Summary

This machine use metal coil as material, through decoiler, roll former, automatic length sizing, cutting off to form special size profile. The whole line use PLC control, AC frequency control to realize continuous automatic production.

Drawings

Technical Flow

Hydraulic decoiler → Entry guide → Pinching and leveling → Hydraulic punching(80 tons puncher) → Roll former → Length sizing cutting → Exit rack

Main Specification

1. 5ton Hydraulic Decoiler

1) Decoiler: Structure of pedestal, braking, mandrel holder, slider narrow and expanding

2) Coil weight: max 4 tons

3) Coil ID: Φ508 mm

4) Coil OD: Φ1500 mm

5) Decoiler range:Φ450-540mm

6) Motor power: 4kw

7) Hydraulic power: 3kw

7) Hydraulic system oil pump: gear pump or vane pump

8) Solenoid Valve: Beijing Huade

9) Inverter: Yaskawa (Japan)

2. Feeding Guide & Leveling Device

1) Leveling width: ≤400mm

2) Leveling type: 2 rolls pinching and 5 rolls leveling (2 up and 3 down )

3) Feeding andLeveling motor power: 3kw

4) Leveling Shaft diameter: about Φ90mm

5) Leveling Shaft material: qualified 40Cr

6) Leveling shaft heat treatment: surface high frequency quenching

7) Reducer: Worm wheel and worm

3. Servo punching device

1) Servo feeding motor power: 2kw

2) Servo motor brand: Yaskawa

3) Puncher: JH21/80T

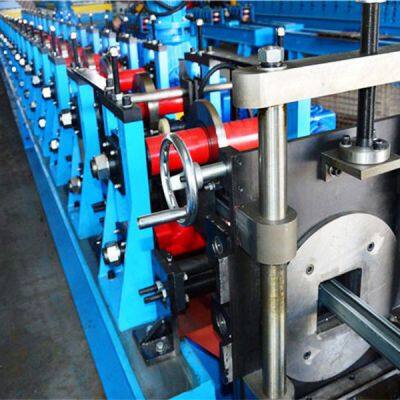

4. Main Roll Former

1) Guide feeding stand: side wheel type

2) Roll former type: cast iron stand type and gear box drive

3) Shaft material: 40Cr hardening and tempering(HB220-260)

4) Bearing diameter: Φ70mm(HRB)

5) Forming motor power: 22kw x 2

6) Roll forming speed: 10-20m/min (not include punching & cutting time)

7) Forming station: about 28 stations and a series of auxiliary rolls ( include roller teeth)

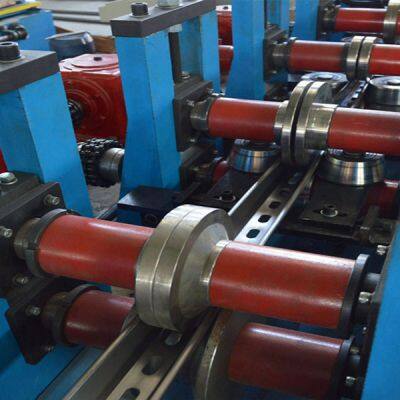

roller teeth picture:

8) Adjust size: change spacer. Spacer is buckled type, loosen the locking round nut of the main shaft section, remove a spacer, install in the designated position, lock the round nut, and adjust the feed width, change the cutting mould can be produced.

9) Spread width of rolling material: based on the actual width of the test plate

10) Length tolerance ≤±1.5mm

11) Roller material: Cr12MOV quenching treatment (HRC58-62)

12) Hard Chromium Coating on Rollers: ≥ 0.05mm

5. Disc saw

1) Cutting mode: sawing (disc saw)

2) Saw blade material: high speed steel

3) Disc saw motor power: 3KW

6. Exit rack: 2 sets

1) Size: 2000mm x2

2) Type: Roller type structure, angle steel welding, no power

7. Electrical control system

The whole line controlled by PLC control and Frequency Speed Control to achieve automatic. The friendly interface can set the batch, product length and quantity.

PLC: Siemens/Panasonic

Encoder: Koyo/Omron

Buttons and contactors: Chnt

Operate panel: Touch screen

Certificate

Main Customers

FAQ

1) Q: Will you deliver the right goods as ordered? How can I trust you?

A: Yes, we will. We are Gold supplier of Made-in-China with SGS assessment (Audit report can be provided). We have cooperated with many customers all over the world with high market reputation, no worries.

2) Q: How to choose the Tube Mill Line?

A: You have to inform us following details:

- The pipe material

- Round pipe range

- Square pipe range

- Rectangle pipe range

- Wall thickness range

- The pipe usage

3) Q: How to choose the Roll Forming Machine?

A: You have to inform us following details:

- Coil material

- Coil thickness

- Coil weight

- Cutting type

- Profiles drawings

- Other special attention

4) Q: How to choose the Slitting Line & Cut to Length line?

A: You have to inform us following details:

- Coil material

- Coil thickness

- Coil width

- Coil weight

- Finished sizes

- Other special attention

55) Q: Where is the nearest airport to your company?

A: Shanghai Putong or Hongqiao Airport.

6) Q: How about your service?

A: Before sales:

- Technical Support: TGMCO will provide detailed technical information such as technical & commercial offer, machine photos, running video, layout, operation manual, and show you working machines in our factory.

- Apply Visa: TGMCO will provide officially invitation letter to apply Visa in china embassy as authority procedures and requirements.

After sales: TGMCO provides comprehensive After Sales Support and Service to meet our customer need.

- Drawings: Provide the foundation drawing, electric scheme and wiring diagram, hydraulic drawing, pneumatic & electric pipeline drawing and other drawings requested by customer.

- Installation and commissioning: TGMCO will send our technicians to customer's workshop for supervision of installation and commission

Training of Customers' technician/workers during commission

- Breakdown Support: We offer 1 year warranty service for main crucial components except consumables

Inform immediate technical assistance and advice to customer by phone or e-mail.

Skilled and experienced engineers are capable of dealing with any type of breakdowns.

Technical service work performed in Customer's site if required.

Urgently supply mechanical or electronic components.

Fast supply of spare parts and wearing parts to cover foreseeable requirements

Packing & Delivery

Not only the Good Machine, but also the Most Attentive Service

Integrity Solution & Turnkey Project

Creat the Value of Steel

Send Inquiry to This Supplier

You May Also Like

-

Curve Roofing Panel Roll Forming EquipmentsUS$ 10000 - 20000MOQ: 1 Set

-

Stainless Steel Galvanized Color Steel Ceiling Panel Roll Former MachineUS$ 10000 - 20000MOQ: 1 Set

-

Stainless Steel Galvanized Color Steel Ceiling Panel Ceiling Board Roll Forming MachineUS$ 10000 - 20000MOQ: 1 Set

-

Stainless Steel Galvanized Color Steel Ceiling Panel Ceiling Board Roll Former Manufacture EquipmentsUS$ 10000 - 20000MOQ: 1 Set

-

Door Frame Cold Roll Forming Machine Bending MachineUS$ 10000 - 20000MOQ: 1 Set

-

Door Frame Cold Roll Forming Machine With Bending EquipmentsUS$ 10000 - 20000MOQ: 1 Set

-

Door Frame Doorcase Cold Roll Forming Machine With Bending EquipmentsUS$ 10000 - 20000MOQ: 1 Set

-

Color Steel PPGI Aluminum Galvanized Roofing Sheet Roll FormerUS$ 10000 - 20000MOQ: 1 Set

-

Color Steel PPGI Aluminum Galvanized Roofing Sheet Roof Board Roll Former EquipmentsUS$ 10000 - 20000MOQ: 1 Set

-

Color Steel PPGI Aluminum Galvanized Roof Board Standing Seam Board Roll Former EquipmentsUS$ 10000 - 20000MOQ: 1 Set