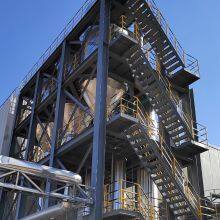

Ammonium Sulfate Crystalline Granule Evaporation and Drying Plant

Ammonium sulfate (NH4)2SO₄ is a versatile chemical compound with various applications in industries such as agriculture, pharmaceuticals, food processing, and more. And it is an inorganic salt that appears as a white, crystalline powder or granules.

And the industrial form of ammonium sulfate product is typically a crystalline powder or granular material. The specific characteristics of the industrial form of ammonium sulfate can vary depending on the manufacturing process and the intended use. Here are some common forms in which industrial-grade ammonium sulfate is available and the industrial production process:

1. Crystalline powder: ammonium sulfate solution, pre-concentration with a multiple-effect evaporator or a MVR evaporator, and the oversaturated liquor is solid-liquor separated in a centrifuge, and the wet crystalline powder are dried in a fluidized bed dryer.

2. Crystalline granule: ammonium sulfate solution, pre-concentration with a multiple-effect evaporator or a MVR evaporator, and special crystallizer is adopted to obtain crystalline granules in bigger size, and then the oversaturated liquor is solid-liquor separated in a centrifuge, and the wet crystalline granules are dried in a fluidized bed dryer.

3. Pellet: Ammonium sulfate pellets are spherical pellets or irregular pellets formed by a process called prilling. Spherical pellets are made with a wet- process prilling, while the irregular pellets are made with a dry-process prilling. Pellets are larger and have a more consistent size compared to granules, they are commonly used as slow-release fertilizers due to their controlled nutrient release properties.

The Ammonium sulfate (NH4)2SO₄ crystalline granule production plant (evaporation and drying) is as below:

Process Characteristics

A forced circulation evaporator is adopted according to the physico-chemical property of ammonium sulfate liquid. As forced circulation evaporator system can effectively prevent the blocking risk of heat exchange tubes caused by ammonium sulphate, and can slow down the formation of fouling on the heat exchange surface at the mean time, improve the heat transfer efficiency, increase the continuous operation time of equipment, and reduce the cleaning frequency.

To ensure the quality of the crystalline salt, FC type crystallizer is used to fully eliminate the supersaturation of the material, increase the crystalline powders, reduce the moisture content of filtered salts, and reduce the energy consumption of the system.

And in consideration of energy-saving, either multiple-effect or MVR type can be adopted according to the energy cost at the project site.

Main characteristics of the forced circulating evaporator:

1. Anti-scaling: It relies on a high flowand low head circulation pump to maintain the forced circulation of the solution, which fills the heat exchanger tube and has a certain flow rate so that the scaling on the heat exchange tubes could be reduced by the flushing of the liquor.

2. Advanced design of separator: Beneficial for crystal growth; and high demisting efficiency.

Send Inquiry to This Supplier

You May Also Like

-

Calcium Chloride Granule Production PlantNegotiableMOQ: 1 Plant

-

Double-effect Forced Circulation Evaporator for Calcium Chloride ConcentrationNegotiableMOQ: 1 Plant

-

Calcium Chloride Solution Preparation and Refining PlantNegotiableMOQ: 1 Unit

-

Ammonium Sulfate Pellet Production PlantNegotiableMOQ: 1 Set

-

SODIUM SULFATE WASTEWATER EVAPORATOR-CRYSTALLIZERNegotiableMOQ: 1 Set

-

Ethanol Recovery System (Ethanol Recovery From Waste Liquid Soap)NegotiableMOQ: 1 Set

-

Ammonium Chloride Evaporation & Crystallization Project Completed With DMF DistillationNegotiableMOQ: 1 Set

-

MVR Evaporator for Lithium Sulfate ConcentrationNegotiableMOQ: 1 Set

-

MVR Evaporator for Anhydrous Sodium Sulfate (Na₂SO₄) ProductionNegotiableMOQ: 1 Set

-

MVR Evaporator for Bio-pharmaceutical Wastewater TreatmentNegotiableMOQ: 1 Set