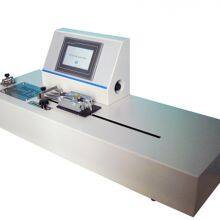

Hot tack is the property of a heat-sealed layer to resist forces that would pull the seal apart while it is still hot. This

property is of vital importance for vertical form fill and seal process (VFFS). HTT-02 Hot Tack Tester measures the strength of heat seals formed between thermoplastic surfaces immediately after the seal has been made and before it cools to room temperature.

ASTM F1921, ASTM F2029,QB/T2358, YBB 00122003

Technical Specifications

Sealing Temperature Ambient~250℃

Temp Accuracy ±0.2℃

Heat Seal Dwell Time 0.1~9999s

Hot Tack Dwell Time 0.1~9999s

Sealing Pressure 0.15MPa~0.7MPa

Sealing Jaws 50mmx10mm Teflon Coated

Sealing Jaws Heating Double Heating

Load Cell 200N

Accuracy 0.5 F.S.

Resolution 0.01N

Stroke 500mm

Gas Source 0.7MPa

Port Size Ф6mm PU Hose

Power AC220V50Hz

1. Hot tack, peeling and tensile test items are integrated in one instrument.

2. Delta P.I.D. temperature controller used and PT100 temperature sensor

3. 7 inch TFT touching screen for easy operation

4. PLC control unit inside

5. Aluminum encapsulated sealing jaws for average heating

6. Multi-group parameter saving

7. Testing speed adjustable from 1~2000mm/min.

8. Auto zeroing, overload and over travel protection

9. RS 232 port and professional software(optional)

Send Inquiry to This Supplier

You May Also Like

-

Micro Printer Gelbo Flex Durability TesterNegotiableMOQ: 1 Set

-

ASTM D1424 Elmendorf Tearing TesterNegotiableMOQ: 1 Set

-

PLC Control Inside Pendulum Hammer Striking TesterNegotiableMOQ: 1 Set

-

Falling Dart Impact TesterNegotiableMOQ: 1 Set

-

Torque Test Instrument TT-01NegotiableMOQ: 1 Set

-

Coefficient of Friction Tester COF-01NegotiableMOQ: 1 Set

-

LT-01 Leak TesterNegotiableMOQ: 1 Set

-

Leak and Seal Strength Tester LSST-01NegotiableMOQ: 1 Set

-

Ampoule Break Force TesterUS$ 1000 - 4000MOQ: 1 Set

-

Carbon Dioxide Volume TesterNegotiableMOQ: 1 Set