Bag in Box Filling Machine for Fully-automatic Liquid Packaging

Fully-automatic BiB Filler | WEB Fed Bag-in-Box Filling Machine

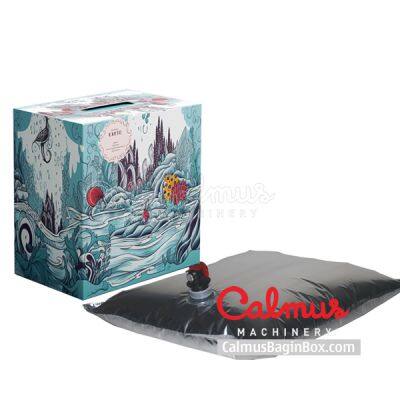

It is a web-fed Bag-in-Box (BiB) Filling Machine made in China and is designed for packaging a wide range of liquids like drinking water, edible oil, post mix syrup, fresh milk and beverage with 2-25L spouted bags. This filling machine features fully automated by employing a PLC and touch screen control system. The whole process of continuous bags feed, decapping, vacuumization (optional), nitrogen injection (optional), filling, capping, cutting apart from continuous bags and transiting to the conveyor can be completed automatically, no human operation required.

This bag-in-box filler is designed with CIP (Clean-in-Place) function and pipeline connection.

Features:

1) Fully-automatic, WEB type bags fed.

2) Easy to use. The touch-screen control system makes operation easy.

3) An electromagnetic or turbine flowmeter employed improves filling precision and truly achieves the quantitative filling.

4) An air filter employed bring clean air to the filling space.

5) Grade 304 stainless steel body and 316L stainless fluid-contact parts.

6) Filling a different capacity bag acceptable only by changing the setting.

7) Options of vacuumization and nitrogen injection available for specific products use.

Specifications:

Applicable bags: pre-cut continuous module or WEB type spouted bags, 2-25 litres. (Spout is called Gland or Flange too.)

Filling capacity:

450-510 bags/hour for 5 litres

360-400 bags/hour for 10 litres

250-270 bags/hour for 20 litres

Power: 1.0 kW

Compressed air: 6-8 bar, 500 NL/min

Procedure:

1) Automatically feed bags.

2) Automatically decap, fill, cap cut apart bags.

3) Automatically exit filled bags.

Fully-automatic. Grade 304 stainless steel construction and grade 316L stainless steel fluid-contact parts. World famous brands of key components and many are imported.

Absolutely EU quality standard, but less than half of EU price.

We also supply the matched box packaging line.

Send Inquiry to This Supplier

You May Also Like

-

Bag in Box Line for Packaging Shortening in BulkNegotiableMOQ: 1 Set

-

Cobot Palletizer Collaborative Palletizing RobotNegotiableMOQ: 1 Piece

-

Polybag Maker Bag Inserter Machine From Roll Stock FilmUS$ 20000 - 30000MOQ: 1 Piece

-

Case Liner Polybag Inserting Machine for Bulk Box PackagingUS$ 20000 - 30000MOQ: 1 Piece

-

Cartoning Machine Monoblock Case Packer for Packaging Butter BricksNegotiableMOQ: 1 Set

-

Bag Inserter Machine for Woven SacksNegotiableMOQ: 1 Set

-

Poly Bag Uncuffer and Top SealerNegotiableMOQ: 1 Set

-

CE Certified Poly Bag InsertersUS$ 20000 - 40000MOQ: 1 Piece

-

Poly Bag Decuffer SealerNegotiableMOQ: 1 Set

-

Bag in Box Uncuffer and SealerNegotiableMOQ: 1 Set