Formstable Big Bags BRC Certificate Food Grade 1 Loop 2 Loop 4 Loop Bulk Bag for Powder 1000kg 1 Metric Ton Two-handle Bag

Which style bag is the most suitable for your application?

● Circular, seamless, or Tubular bulk big bags

Bulk big bag with seamless made from pp woven fabric on a circular loom and cut to a suitable bag height. This eliminates the need for vertical seems. The tubular shape design is ideal option for fine or powder materials. Bottom of bag can be square or circle shape available.

● U-Panel Bags

U-Panel big bags consists of a large “U” piece of fabric with 2 side panels sewing to each side to fulfill a bag shape. This style bag will maintain a square shape when filled, especially for bags with baffles. U-panel big bags can offer high safe working loading weight and solid durability.

4 Panel Bags

4 Panel big bag constructed from 4 separate fabric panels which are sewn together at the edges to form a bag. A separate square sheet of fabric is used to make the bottom of the bulk bag.

Baffled Bags

Baffled bulk bags are typically 4-panel or U-panel or Circular bags which using internal fabric baffles to improve the bag's squareness and stability. These bags are designed to maximize storage and save shipping space.

FIBC Bulk Bag Options

● UN Certified

UN Certified bulk bags are specifically designed to store and transport hazardous materials.

When hazardous goods are packed in bags, the UN mark for the product should be printed on the body of bulk big bag.

● Food Grade

Food grade bulk bags that are made for food contact and food related products. It should be manufactured in BRC and AIB certified facilities. These bags are made from virgin polypropylene resin meeting with FDA food grade standard. Our food grade bags can also provided with LDPE or LLDPE inner liners approved by pharmaceutical and food usage.

● Electrostatic Properties.

1. Type A: With no special electrostatic safety features.

2. Type B: Type B bags are not able to generate brush discharges.The wall of big bag can provide a breakdown voltage of 6 kilo-volts or even less.

3. Type C: Also named conductive big bag which constructed from electrically conductive fabric weaved within conductive thread or tapes to prevent electrostatic charges on grounding.

4. Type D: Also known as anti-static big bag, normally regarding to those bags which have anti-static properties without grounding requirements.

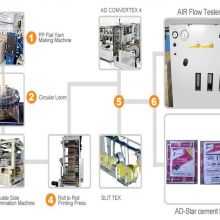

Bulk Big Bag manufacturing Facility

Our world Class Manufacturing Facility produces bulk big bags, PP woven fabric, Inner liner, Webbing or lifting straps.

Bag Facility Capacity:

● 8,000 FIBC Bags and 50,000 PP Woven Bags per Day.

● 100,000 meters of woven fabric per Day.

● 25,000 meters of PE liners per Day.

● 40,000 meters of Lamination per Day.

● 120,000 meters of Webbing per Day.

CONTACT US:

Mr.Daniel

Mobile Phone:+86-13802155833

WeChat:+86-13802155833

WhatsApp:+86-13802155833

Telegram:+86-13802155833

E-mail: tjwoking@163.com

ppwovenbagpacksack@gmail.com

Product Specification

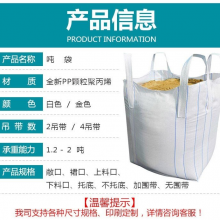

Dimension: | 94x94x122cm or 37''x37''x48'' |

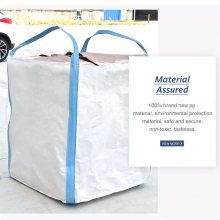

Material: | 100% Virgin PP material |

Feature: | Recyclable |

Top Option: | Fully open or filling spout |

Bottom Option: | Flat Bottom or Discharge spout |

Fabric weight: | 60gsm- 250gsm |

Loop Option: | Side seam or Cross corner lifting loops |

Safe Loading: | 500kgs - 3000kgs |

Model item | Tubular, U-panel, 4-panel, Baffle |

Color: | White, Beige, Black, Green, Blue etc. |

Lamination: | 1 or 2 side lamination or BOPP lamination |

Inner liner: | Tubular or Form fit liner or EOVA liner |

Usage: | Chemical material or Mineral |

Sewing: | Normal or lock stitch or Chain stitch |

Packing: | On bales or Pallets as customer's require |

Safety factor: | 3:1, 5:1, 6:1 |

FIBC (Big bag) Glossary Terms:

Bag Size: The dimension of an FIBC measured from the seam to seam for Length, Width or Height.

Body Fabric: Main fabric used on bag body of a u-panel, four panels or circular bag. Coated/ laminated or uncoated/ non-laminated.

Bottom Fabric: The bottom material of a tubular or four panel bag.

Bottom Spout: Also named Discharge Spout, used as an outlet to empty the contents of the BIG BAG.

Breathable Fabric/ Bags: Fabric/ bags with uncoated or non-laminated.

Circular Big Bag: Also called a tubular big bag, it is made from fabric weaving out from a circular loom, which is then cut into a proper length for specified bag height, thereby eliminating the vertical seams on each of the bag’s sides.

Cone Top: A variation of an inlet, where the top is a pyramid-type to allow over filling of the bag. Also called a conical top.

Denier: The weight of yarn per 9,000 meters in gram.

Discharge Spout: Also called bottom spout, used as an outlet to empty the contents of the FIBC bag.

Fabric Weight: The measure of the fabric weight in ounces per square yard or grams per square meter. A typical standard weight is 6.5 oz./sq.yd or 180 g/㎡.

FIBC: Short name of Flexible Intermediate Bulk Container.

Fill Spout: Also called inlet spout or top spout, used as the inlet for filling an FIBC bag. It is designed to fit the customer’s filling chute during loading.

Form-Fitted Liner: Designed to form the exact shape of the FIBC outer bag. Form-Fit Liners will allow improved filling and complete discharging of product.

Lift Belt: Also called a lifting loop or lifting straps, supporting the bag’s Safe Working Load, (SWL), of a filled bag during handing & transport. It may be made of either a stiff strap or soft strap. It comes in various widths and strengths according to specified each bag specification. Typically lift loops have a tensile strength between 3000 and 5000 pounds.

Loop Height: The free loop height measured from top edge of bag body to the middle of the free end of the link belt.

Send Inquiry to This Supplier

You May Also Like

-

Breathable FIBC Jumbo Super Sack Bulka Bags 1 Tonne Good Price One And Two-point Lift Bags Cement Jumbo BagsUS$ 0.102 - 0.227MOQ: 5000 Pieces

-

PP Woven Bulka Container Bag Tubular Big Bag With 1 or 2 Lifting Points for Sugar PP Maxisacos Woven Super SacksUS$ 0.102 - 0.227MOQ: 5000 Pieces

-

Sling Big Bag 1000kg for Cement Custom Color Printing Feature Weight High Bottom Loop Safety 5:1 FBIC Lifting Container Rice BagUS$ 0.102 - 0.227MOQ: 5000 Pieces

-

Sling Jumbo Bag Flexible Palette Woven Virgin Polypropylene Size 100cm x 100cm Cargo Lifting Bags FIBCUS$ 0.102 - 0.227MOQ: 5000 Pieces

-

Sling Pellet Bags Heavy Duty Plastic Storage FIBC Bag Jumbo Super Sacks 1 Ton 2 Ton Size a Metric Cement Bulka BagUS$ 0.102 - 0.227MOQ: 5000 Pieces

-

Super Sling Sack Flexible Palette Tote 1100lbs 2200lbs 3300lbs 4400lbs1 & 2 Schleife FIBC Big BagUS$ 0.102 - 0.227MOQ: 5000 Pieces

-

Pre-sling FIBC Sacks Soft Cement Lifting Bags for Building Materials 1MT Tote Bags Soft Pallet Jumbo Sling BagUS$ 0.102 - 0.227MOQ: 5000 Pieces

-

Jumbo-sacks for Cement Sands Bulk 1 Ton 1.5 Ton 2 Ton Sand Bulk Sling FIBC Big Bag Jumbo Bag 1 Ton FibcUS$ 0.102 - 0.227MOQ: 5000 Pieces

-

Jumbo-sacke for Zement Chemical Resistant Loop Tote Type 1 Ton 1.5 Ton 2 Ton Lifting Bags for Cement Sand Bulk SlingUS$ 0.102 - 0.227MOQ: 5000 Pieces

-

Durable Fertilizer Bulk Bags 30kg , Dustproof Hdpe / Bopp Laminated Bags Anti - SlipUS$ 0.102 - 0.227MOQ: 5000 Pieces