Hot Melt PUR Laminating Machine

Hot Melt Film Laminating Machine

KUNTAI Laminating machine vidoes links:

Hot Melt PUR Lamination Machine https://youtu.be/j3tVeIdim04

Automatic Laminating Machine for Fabric with Membrane or Film https://youtu.be/i2cX6s6syfs

Laminating Machine for Shoes, Bags, Box, etc. https://youtu.be/zi02S_LJ92k

Automatic multifunctional laminating machine https://youtu.be/puqwQ2JnwQQ

Laminating Machine for :

1. EVA + PVC, PU or Artificial Leather

2. EVA + Fabric (for shoe materials, etc)

3. Neoprene + Fabric (for diving suit, etc)

4. PU Foam + Fabric (for bra, vehicle cushion, etc)

5. TPU Film + Fabric. (for climbing clothing, camouflage uniform, etc)

6. Fabric + Fabric. (for clothing, medical supplies, etc)

Hot Melt Adhesive

In industrial use, hot melt adhesives provide several advantages over solventbased adhesives. Volatile

organic compounds are reduced or eliminated, and the drying or curing step is eliminated. Hot melt ad

-hesives have long shelf life and usually can be disposed of without special precautions.

The most advanced hot melt adhesive, moisture reactive hot melt glue (PUR & TPU), is highly adhesive

and environmentally friendly. It can be used for lamination of 99.9% textiles. The laminated material is

soft and high temperature resistant. After moisture reaction, the material will not be easily affected by the

temperature. Besides, with lasting elasticity, the laminated material is wear resistant, oil resistant and ag

-ing resistant. Especially, mist performance, neutral color and other various features of PUR makes medi

-cal industry application possible.

When PTFE, PE, TPU and other functional waterproof and breathable films are used in laminating, water

-proof and heat preserving, waterproof and protective, oil & water & gas filteration and many other different

new materials will be created. The demands of garment industry, motor manufacturing, medical industry,

environment protection industry will be met.

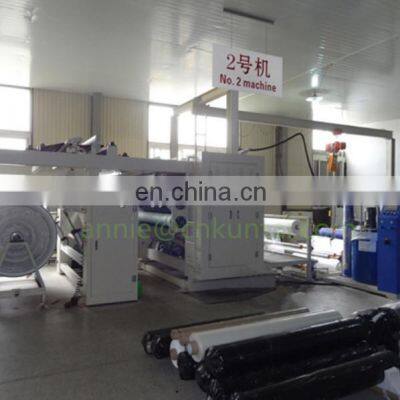

Our hot melt laminating machine is mainly consisted of fabric rewinding and unwinding units, fabric and film

transmission systems and tension controller, film unwinding and lining or film carrier rewinding device, hot

melt glue melting unit (optional), pump (optional), conduction oil source system (optional), glue dot transfer

unit, laminating device, cooling device, PLC and other devices. It is compact, highly automatic and easy to

maintain.

Standard Technical Parameters (Customizable):

| Model: | KT-PUR-1800 |

| Maximum Material Width: | 1600mm |

| Machine Roller Width: | 1800mm |

| Gluing Amount: | 5-80g/m2 |

| Machine Speed: | 10-60 m/min |

| Power: | 45.0 KW |

| Electric Current and Voltage: | Customizable |

| Estimated Net Weight: | 11000 KGS |

| Estimated Dimension: | 11800 x 3400 x 3600 mm |

Key Features:

- Hot melt adhesives makes possible environmental friendly products and realizes no pollution during the whole process of lamination.

- With this type of laminating machine, materials are firmly bonded and products are soft, comfortable, washable and breathable.

- Controlled by Programmable Logic Controller system with touch screen and modular designed structure, this machine can be easily and simply operated.

- Famous brand motors and inverters can be installed for stable machine performance.

- Non-tension unwinding unit makes laminated materials smooth and flat, guaranteeing good bonding effect.

- Fabric and film openers also makes materials feed smoothly and flatly.

- For 4-way strechable fabrics, special fabric transmission/conveyor system can be installed on the laminating machine.

- Parallel centering unit makes sure the materials feed in order.

- Specially designed gluing system well controls the adhesive amount and guarantees precision.

- For the hot melt adhesive melter, temperature control is accurate and stable.

- Final laminated materials can be rewinded into small rolls or large rolls.

- Low maintenance cost and less running noise.

- Advanced technology, secure quality control and satisfactory aftersales service make our lamination machines the first choice for customers both domestically and internationally.

Laminating Machine

Inner Package: Protective Film, etc

Outside Package: Standard Export Container

- Machines well packed with protective film and loaded in export container;

- English version operation manual and technical data;

- One-Year-Period wear parts;

- Tool kit

Engineers Overseas Service Available for Laminating Machine

1. Are you a trading company or a manufacturer?

We are a manufacturer with more than 30 years of manufacturing and R & D experience.

2. Where is your factory?

We are located in Yancheng, three and a half hours drive from Shanghai, China.

3. Do you have a personal R & D department?

Yes, we have established Kuntai R & D centers in Europe and the famous University of Padova in Italy. We always believe in technology- and market-oriented research. Every year, we develop a series of solutions to practical field application problems and develop new machines for our customers.

If you have any new ideas for our machines, please feel free to contact us! We will definitely turn your ideas into designs. Our goal is to solve customers 'problems in every field, achieve better material finishing / processing effects, and become customers' think tanks.

4. How do I trust your quality?

We have a strict and scientific quality control management system, and have passed the rigorous CE and ISO international certifications to maximize the quality of our products.

We have professional quality control personnel. For each step of our machine production, a set of quality control teams will be responsible for checking. The following steps can be performed before the item passes all inspections.

At the end of the machine assembly, a series of tests will be performed. We will not deliver until the machine passes all tests.

We provide a one-year warranty for our machines. Generally, our customers have used our machines for at least 5 years, 8 years or even 10 years.Throughout the life of our machines, spare parts will be replaced at cost.

5. How to operate the machine?

We have never used such a machine before. We just want to expand our business and start a new business.do not worry! When buying our first machine, almost the majority of overseas customers were in the same situation. We have skilled and experienced follow-up service staff who have developed a complete solution to meet the needs of customers like you. In addition, we have a team of professional engineers with rich experience in installation and commissioning, which can perform installation, testing and operation guidance of overseas machines.

Send Inquiry to This Supplier

You May Also Like

-

Roll to Roll Dry Lamination MachineUS$ 5,000 - 10,000MOQ: 1 Set

-

High Quality With CE Waste Tire Baler Machine Vertical PressesUS$ 73,800 - 98,000MOQ: 1 Set

-

Hot New Machine EPE Foam Sheet Laminating MachineUS$ 1,000 - 50,000MOQ: 1 Set

-

Sportswear Suit Professional Jogging SuitsNegotiableMOQ: 1 Set

-

Fiber Aluminum Laser Cutting Machine High Precision 3000 X 1500 mm Cut AreaUS$ 3000 - 100000MOQ: 1 Set

-

Customized High-strength Polyester OEM PET Laser OHP Film With Smooth And Bright SurfaceNegotiableMOQ: 1 Set

-

A5 / A6 Waterproof PET Clear Laminating Pouches Film For ID Cards, PassesNegotiableMOQ: 1 Set

-

Custom Medical Injection Molded Plastic Parts, Cosmetic Packing Moulded ComponentsNegotiableMOQ: 1 Set

-

Customized Laminating Machine Parts From ChinaUS$ 15.99 - 33.99MOQ: 100 Pieces

-

Best Quality Biscuit Laminating MachineUS$ 100,000 - 1,000,000MOQ: 1 Set