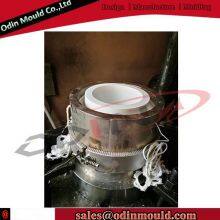

BMC Compression Mould Plastic Mould Customize Design Application of BMC molding compound First, electrical components Low-voltage categories: RT series, isolating switches, air switches, switchboards, meter housings, etc.; High-voltage type: insulator, insulation cover, arc-extinguishing cover, closed lead plate, ZW, ZN vacuum series. Second, auto parts lights, that is, Japanese headlight reflectors are almost all made with DMC; Automobile igniter, separation disc and trim board, speaker box, etc.; Third, the motor components Air conditioning motor, motor shaft, coil bobbin, electric and pneumatic components. Fourth, daily necessities Microwave tableware, electric iron shell and so on. Packaging, transportation, storage BMC series molding compound is packaged in a composite film bag, each bag is 25 kg, and then packed into a carton after being wrapped;

|

You can send any of kind above drawing or samples data to us ask quote

Our company can customized plastic parts for customer,possesses advanced Injection Molding Machines,such as 1250T, 780T, 450T, 360T, 250T, 160T, etc in injection molding.

It also comes with one gas-assisted injection equipment, which can produce roof handle products such as hollow.

For mold spare parts, such as springs, thimbles, hot runner accessories, etc., our company will provide customer maintenance and use free of charge.

Order Manufacturing Process

Send Inquiry to This Supplier

You May Also Like

-

Automotive Radiator Grille Tooling Mold DesignNegotiableMOQ: 1 Set

-

Vegetable Bread Crate Injection MouldNegotiableMOQ: 1 Set

-

Plastic Medical Products Injection MoldNegotiableMOQ: 1 Set

-

Plastic Fan Blade Mold Plastic Fan MoldNegotiableMOQ: 1 Set

-

Plastic Faucet Mould Injection MouldNegotiableMOQ: 1 Set

-

Plastic Injection Food Box MouldNegotiableMOQ: 1 Set

-

Home Garden Plastic Shovel MoldNegotiableMOQ: 1 Set

-

Plastic Auto Rubber Mud Guard MouldNegotiableMOQ: 1 Set

-

Plastic Transparent Chair MouldNegotiableMOQ: 1 Set

-

Tpu Injection For Chopping BoardNegotiableMOQ: 2000 Pieces