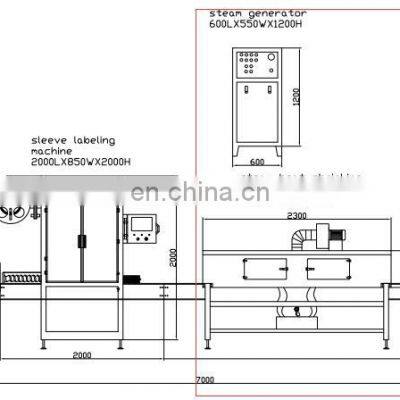

Manual Bottle Shrink Labeling Machine / Semi Automatic Labeler Machine

Manual Bottle Shrink Labeling Machine / Semiautomatic Labeler Machine

Brief introduction

1. Shrinkage film volume label rack, match with adjustable device, convenient to adjust

according to differ volume label 5″~10″paper tube.

2. Simply installation, then can convenient for square and round bottle.

3. No need of instrument, rotary mechanism is convenient to adjust, apply to differ bottle type.

4. Unique sleeve labeling method, adopt to pressing sleeve labeling method,

not only convenient but also reasonable.

5. Auto controlling feeding system, level-off shrinkage film materials and regulate/adjust strain simultaneity.

6. Unique design knife plate, within specification scope, can avoid changing knife base,

knife changing is quick and conveniently.

7. Middle guide-pole clip system,mould changing is more quick, no need any instrument.

8. Label location system, can promote and demote in-phase adjust location according to specific bottle type requirement.

9. Adopt to Japanese import servo system and high-sensitivity photoelectric, label cutting precision is highly.

10. Stainless steel electric equipment controlling case, controlling adopt to Thinget PLC

11. Adopt to advanced man-computer Interface auto controlling technology, key electric component all adopt to international famous industrial brand

shrink tunnel and steam generator:

Main technical data:

1.1 Brief Introduction

1) GD-2300 Steam Heating Shrink Tunnel can be applied to different and irregular bottle types, e.g. round,square and flat bottles.

2) It adopts seamless tube, the distribution of low-pressure steam drum and the spout of steam use the separation style which make the tunnel smooth.

3) The steam nozzle is divided to three adjustable segments; the height, position and steam output of each segment can be adjusted respectively; this guarantees a perfect shrinking effect.

4) The whole machine is made of stainless steel with heat preservation, it not only saves energy, but also match with the international safety standard.

5) The reductor and transportation machine is made by Spirax Sarco which has a good working environment.

6) The stainless steel defrosting tray collects condensed water.The whole machine adopts the water-proof design with the convenience of operation and maintenance.

1.2 Technical Parameter

|

No. |

Item |

Technical data |

|

1 |

Input Voltage Supply of Blower |

1, 220 VAC |

|

2 |

Input Voltage Supply of Steam Generator |

380V/ 50 Hz |

|

3 |

Working Pressure |

<= 0.1 Mpa |

|

4 |

Dimension of Shrink Tunnel |

L2300mm× W700mm × H1750mm |

|

5 |

Weight |

150Kg |

2. Steam Generator

2.1 Brief Introduction

1) The water is feed into the series of wholly automatic electrical heating generator by high pressure potential vortex pump made of copper with short water-supply time and durable service.

2) A floating ball for liquid level is fixed in the water tank to automatically control the water inlet.

3) Working system is all automatically controlled.After connecting the water supply and power supple for 5 minutes or so,it can output the steam continuously with high working efficiency.

2.2 Technical Parameter

|

No. |

Item |

Technical data |

|

1 |

Input Power Supply |

3 Phases 380V/220V |

|

2 |

Input Power |

24KW |

|

3 |

Steam Pressure |

0.4Mpa~0.7Mpa |

|

4 |

Water Tank Volume |

48L |

|

5 |

Vapor Generation Value |

25.8Kg/h |

|

6 |

External Dimension |

760mm*670mm*1360mm |

|

7 |

Weight |

125Kg |

|

RO System

This RO system we can make to match up with your water filling machine from capacity from 500L/Hr to 50000L/hr. This system included sand filter, carbon filter, sodium exchanger, precision filter, Reverse Osmosis, UV, Ozone generator, Ozonized Tower, Pure water tank. This system is made of SUS304 or SUS316 material, thickness is 2.5mm-3mm we promised.

|

|

Blowing Machine with different options

1. Semiautomatic Blowing Machine for 800BPH-2000bph from 0.2-2.5L bottle with 2 or 4 cavities. 2.Full automatic blowing machine from 2 cavity, 4 cavity, 6 cavity, 8 cavity, 9 cavity,etc from 2500BPH to 12000BPH for 500ml bottle. |

|

|

Automatic PVC sleeve labeling machine

Capacity: 100-350bottles/min can be chosen Label material: PVC PET OPS, etc Bottle material: PET PE PP Glass Bottle Diameter: 28 ~ 120mm Bottle Height: 15~320mm Bottle shape: round, square, ellipse, rectangular Label length: 30~250mm(max) |

|

Automatic pet film shrink packing machine

Flow: Feeding→ pushing bottles→ film covering and sealing→ shrinking→ cooling Speed: 8-12packages/min Power (rated/real): 26kw / 16kw Max. packing size: 420*300*350mm(LxWxH) Max. sealing size: 650mm |

Q1: How to find suitable machine or complete beverage production line?

A1: Looking for beverage filling machine in www.grandeemachine.en.china.cn

•Enquiry: Contact us by email, phone call, fax, Instant Messenger (Trade manager, Skype, WhatsApp, Wechat) and let us know your requirements

• Discussion: Specify the items and what are you exactly looking for.

Q2: Are you a trading company or a manufactory?

A2: We are the manufacture of water/beverage filling machine and water treatment system over 10 years.We just not only sell drinking water machines and other related equipment , Quality is our culture. We have rich experienced engineers with technicians working team , providing good and after-sales service term , professional salesman terms .

Q3: Do you have technical support after we purchased your machines?

A3: We will arrange our professional technical to go aboard to your factory, they will help you and teach you how to install and maintenance the machines which you purchased. Or help you to fix machine when it has problems.

Q4: If you buy our machines, can you offer us wear-out spare parts?

A4: We provide our high quality machine 2 years guarantee , and we will also offer you 2 years wear-out spare parts for free. Once your machines broken or doesn't work within 2 years and you can't solve it, firstly, we will try to help you to find problems from your words description by phone or other communication tolls. Secondly, if the phone solutions still not work, our engineers will go to your factory to solve it. Meanwhile, they will teach you the related experiences for fixing.

Send Inquiry to This Supplier

You May Also Like

-

UV Crystal Label DTF Machine for Glass, Metal, Plastic, Wood, Cloth, Ceramics Etc.NegotiableMOQ: 1 Set

-

Handheld Marking MachineUS$ 95 - 100MOQ: 5 Pieces

-

Industrial Ice Pop Fold Label MachineNegotiableMOQ: 1

-

TOWA APN-60 Labeler,RFID Tag Label ApplicatorUS$ 140.16 - 166.67MOQ: 50 Pieces

-

Indoor Touch Screen LCD Self Service Payment Kiosk With 58mm Kiosk PrinterNegotiableMOQ: 1 Piece

-

Booster Brand Label Attaching MachineUS$ 1 - 999MOQ: 1 Set

-

18 Stainless Steel Sleeve and Shrink Labeling Machine +86 15136240765US$ 2,000 - 5,000MOQ: 1 Set

-

Manual Sticker Labeling MachineUS$ 5,000 - 9,000MOQ: 1 Set

-

Made In China Bottle Label Peeling Machine With DiscountUS$ 1,999 - 4,999MOQ: 1 Set

-

Hot High-tech Semi-automatic Pneumatic Flat Bottle Labeling MachineUS$ 3,000 - 15,000MOQ: 1 Set