Candy/Chocolate/Protein/Cereal Bar Packaging Machine

Product Application

MAIN TECHINICAL PARAMETER | ||

Packing Speed | 50-1000pcs/min | |

Product Dimensions | According to real product size | |

Total Power | 9.5kw | |

Outside Dimensions | 8900mm*1180mm*1786mm(L*W*H) | |

Net Weight | 3300kg | |

Power Source | 400V;50HZ,3phase(can customized) | |

Main Features

1. NINE Servo motors, touch screen control.

2. Automatic feeding for the complete packing line.

3. Automatic belt speed adjustment through frequency converter, every conveyor belt is individual.

4. Conveyor belt automatic deviation device through cylinder and photocell.

5. Automatic temperature cooling through the air condition with two fans, air cooling or water cooling available.

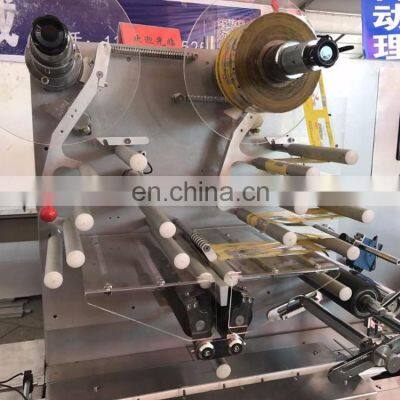

6 .Double paper rollers, automatic paper splicer device (paper splicer device designed according to Germany Bosch)

All the feeding belt are individual speed control by individual frequency converters, it can adjust the speed in the touch screen conveniently. easy take off and installation.

The belt rollers use the rubber materials in case the belt slip.photoelectric tracking system.

Automatic feeding high speed packing machine

Belt Discharging Conveniently

The both sides install the teflon. It can reduce the friction with the products.

The machine equips with the fan to position the product in the hole belt precisely.

Water cooling for the belt

Double Paper rollers structure and fast automatic paper splicer designed according to Germany Bosch as below.

1.One year guarantee for the quality, if components are damaged naturally, we will replace it freely. If Manually damaged, the clients

Response for the costs.

vide the complete installation, debugging, technology support and staff training.

3.permanent accessory parts supply only to our clients for competitive price, quick response for the after-sales service.

Payment Terms:40% T/T in Advanced, the balance should be paid before delivery.

Delivery time: 30 days after the deposit.

Package: Seaworthy Wooden Case.

Shipping:By Sea.

Q1: How to find a packing machine suitable for my product?

Tell us about your product details and packing requirements.

1. What kind of product would you like to pack?

2. The bag size of you need for the product packing ( the length, width).

3. The weight of each pack you need.

4. Your requirement for the machines and the candy shape.

Q2: Is engineer available to serve oversea?

Yes, but the travel fee is responsible by you.

In order to save your cost, we will send you a video of full details machine installation and assist you till the end.

Q3. How can we make sure about the machine quality after packing the order?

Before delivery, we will send you the pictures and videos for you to check the machine quality.

And also you can arrange for quality checking by yourself or by your contacts in China.

Q4. Can you explain me the whole transaction process ?

1.Sign the contact.

2.Arrange 40% deposit to our factory.

3.Factory arrange production.

4.Testing & detecting the machine before shipping.

5.Inspected by customer or third agency through online or site test.

6.Arrange the balance payment before shipment.

Send Inquiry to This Supplier

You May Also Like

-

Tying Machine for Supermarket Food Pack Suitable for Plastic Bag, Fabric, Net Bag Etc.NegotiableMOQ: 1 Set

-

Waste Plastic Film Compression Baler, Waste Plastic Bottle BalerUS$ 27000 - 28000MOQ: 1 Set

-

Automatic Biscuit Multi Head Weighing Packaging Machine/Biscuits Pillow Packaging Machine For CookiesNegotiableMOQ: 1 Set

-

Automatic Hydraulic Cardboard Baler Machine Waste Paper Plastic Press Horizontal BalerNegotiableMOQ: 1 Set

-

Market Price Net Mesh Bag Packing Machine Orange Packing Machine Citrus Packing MachineNegotiableMOQ: 1

-

Keestar NP-7K Portable Bag Closer Handheld Sewing MachineNegotiableMOQ: 1 Set

-

Small Waste Plastic Compression MachineUS$ 3,068 - 4,199MOQ: 1 Set

-

Cool TowerUS$ 3,000 - 3,000MOQ: 1 Set

-

Improving Working Efficeincy Elastic Staple Fastener Machine VNS SystemUS$ 1,200 - 2,000MOQ: 1 Piece

-

Portable Bag Closing Machine DA-RNegotiableMOQ: 1 Piece