Lvrui Machinery B300 Air Chute Dry Ash Conveying Chute Cement Powder Conveying Equipment

1、 Overview

Air conveying chute is a kind of pneumatic conveying equipment widely used for conveying dry powder materials. It is often used for conveying cement and raw meal in the cement industry.

Compared with screw conveyor, belt conveyor and other conveying equipment, it has no rotating parts, easy to maintain, good sealing, no noise, less power consumption, convenient to change the conveying direction, and can feed and discharge at multiple points.

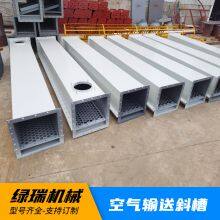

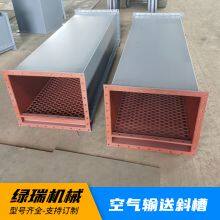

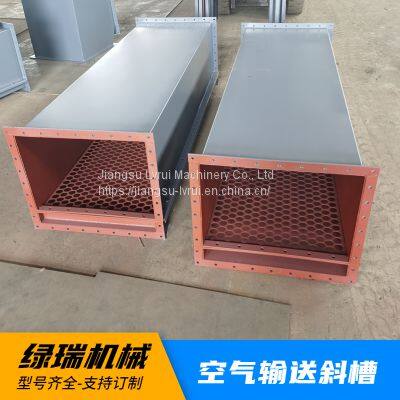

The air conveying chute is made of several ordinary thin steel plates and connected with other accessories by bolts. An air permeable layer is sandwiched between the upper and lower tank bodies, and the air conveying chute is installed at a certain oblique angle from the feeding end to the discharging end from high to low.

The upper part of the permeable layer is the material chamber, and the lower part is the air chamber. When the gas with a certain pressure is blown into the air chamber, the material is fluidized through the permeable layer. Therefore, the material flows in the tank like a fluid under the action of gravity, and the fan is usually used as the air source. The excess air in the material room is extracted by the dust collector through the exhaust port of the air conveying chute.

2、 Structure and arrangement of air conveying chute

3、 Refer to table for conveying capacity of air conveying chute

Chute specification | XZ200 | XZ250 | XZ315 | XZ400 | XZ500 | XZ630 | XZ800 | |||

Groove width | mm | 200 | 250 | 315 | 400 | 500 | 630 | 800 | ||

| Transport capacity | i=4° | cement | t/h | 22 | 40 | 70 | 130 | 220 | 320 | 400 |

Raw materials | 16 | 30 | 55 | 100 | 165 | 245 | 310 | |||

i=6° | cement | 40 | 65 | 120 | 250 | 400 | 610 | 765 | ||

Raw materials | 30 | 55 | 90 | 185 | 300 | 455 | 565 | |||

i=8° | cement | 50 | 80 | 140 | 300 | 470 | 720 | 900 | ||

Raw materials | 36 | 65 | 110 | 225 | 355 | 540 | 670 | |||

i=10° | cement | 60 | 100 | 170 | 380 | 570 | 900 | 1080 | ||

Raw materials | 45 | 80 | 140 | 285 | 425 | 670 | 800 | |||

i=12° | cement | 70 | 120 | 205 | 455 | 685 | 1080 | 1295 | ||

Raw materials | 50 | 95 | 165 | 340 | 510 | 805 | 960 | |||

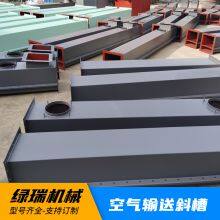

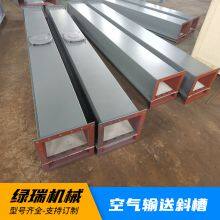

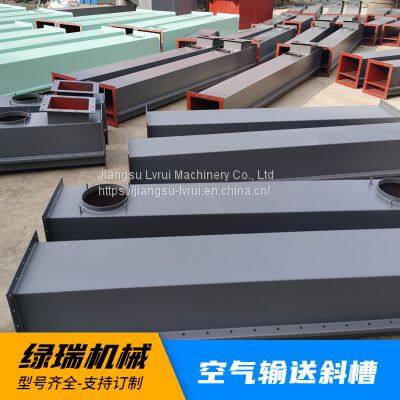

4、 Product real map

Send Inquiry to This Supplier

You May Also Like

-

Air Conveying Chute Cement Pneumatic Conveying Chute XZ400 Air ChuteNegotiableMOQ: 1 Set

-

Air Conveying Chute for Cement Plant XZ500 Air Chute Pneumatic Conveying EquipmentNegotiableMOQ: 1 Set

-

Air Conveying Chute AS400 for Cement Dry Ash, Slag Powder Conveying With Perforated Plate and Breathable ClothNegotiableMOQ: 1 Set

-

AS500 Air Conveying Chute Cement Powder Conveying Chute Pneumatic Conveying ChuteNegotiableMOQ: 1 Set

-

Air Gravity Conveyor for Efficient Powder ConveyingNegotiableMOQ: 1 Set

-

XZ500 Air Slide ConveyorNegotiableMOQ: 1 Set

-

AS-315 Air Conveyor Chute Pneumatic Conveying of Cement Dry AshNegotiableMOQ: 1 Set

-

Aero-Slide Conveyor | Airslide Gravity ConveyorsNegotiableMOQ: 1 Set

-

Slide Gate Valve\\Air Slide ConveyorNegotiableMOQ: 1 Set

-

Air Transport Chute XZ315 Cement Transport Chute Installation Angle 6-12 DegreesNegotiableMOQ: 1 Set