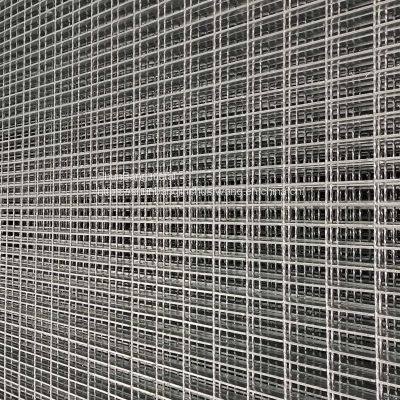

325 Metal Grating: Factory Pressure Welded Steel Grating, Car Wash Room Floor Drain Pool, Sewage Pool Grate, Galvanized Steel Grating

The difference between cold galvanizing and hot galvanizing for galvanized steel grating

The surface treatment methods are different: hot dip galvanizing is also called hot dip galvanizing. It melts the zinc ingot at high temperature, puts some auxiliary materials, and then immerses the metal structural parts in the galvanizing tank, so that a layer of zinc layer is attached to the metal components. It belongs to electrochemical reaction.

Generally, the zinc content of the hot-dip galvanized steel grating is about 70UM, the adhesion and hardness of the galvanized layer are good, and the corrosion resistance of the hot-dip galvanized steel grating is relatively good, which is generally suitable for outdoor use. "Cold plating" is "electroplating", that is, the zinc salt solution is electrolyzed to coat the plated parts. Generally speaking, there is no heating, and the amount of zinc on the galvanized parts is very small. The amount of zinc on the galvanized parts is only about 10 grams. It belongs to physical treatment, and it is easy to fall off in wet environment. The corrosion resistance of cold galvanized steel grating is not so good, and it is generally used indoors.

Color difference: generally, the color of hot-dip galvanized steel grating is bright and silvery white, while the color of electro galvanized steel grating is dark and dirty white.

The use time is different: the hot-dip galvanized steel grating can be used for about 30-40 years, while the cold galvanized steel grating is easy to rust and slowly corrode, so it can't be used for about 1-2 years

Send Inquiry to This Supplier

You May Also Like

-

Sewage Treatment Grating Cover Plate Manufacturer FRP Trench Cover Plate Drainage FRP Grating Cover Plate Supporting SampleNegotiableMOQ: 1 Square Foot

-

The Platform Steel Grating Made by the Manufacturer is Galvanized and Durable. The Ditch Cover is Made of Building Steel GratingNegotiableMOQ: 1 Square Foot

-

304 Stainless Steel Platform Steel Grating Stainless Steel Grating Trench Cover Stair Step GratingNegotiableMOQ: 1 Square Foot

-

Pressure Welded Steel Grid Plate Galvanized Municipal Sanitation Steel Grid Plug-in Grid Plate Stainless Galvanized Steel Grid WholesaleNegotiableMOQ: 1 Square Foot

-

Galvanized Pressure Welded Anti-skid Grating Plate Hot-dip Galvanized Steel Grating Cover Plate Hot-dip Galvanized Special-shaped Steel GratingNegotiableMOQ: 1 Square Foot

-

Galvanized Steel Grid Plate, Stainless Steel Grid Plate, Floor Grid Plate, Grid Plate, Ditch Cover Plate, Plug-in Steel Grid PlateNegotiableMOQ: 1 Square Foot

-

G325 Metal Grating: Factory Pressure Welded Steel Grating, Car Wash Room Floor Drain Pool, Sewage Pool Grate, Galvanized Steel GratingNegotiableMOQ: 1 Square Foot

-

Drain Cover Plate: Drain Cover Plate for Road and Car Washing; Entity Manufacturer: Hot Dip Galvanized Anti-skid Steel Grating PlateNegotiableMOQ: 1 Square Foot

-

Drain Cover Plate: Drain Cover Plate for Road and Car Washing; Entity Manufacturer: Hot Dip Galvanized Anti-skid Steel Grating PlateNegotiableMOQ: 1 Square Foot

-

Steel Grating; Sewage Treatment; Steel Grating; Construction Engineering; Non Slip Galvanized Steel Grating; Parking Ditch CoverNegotiableMOQ: 1 Square Foot