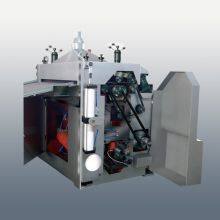

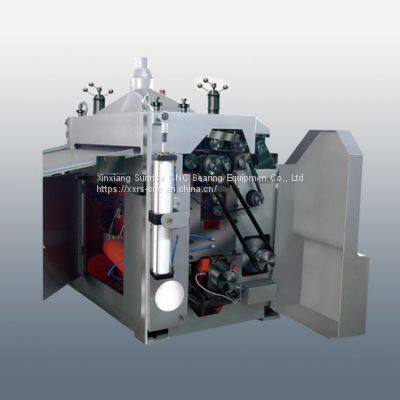

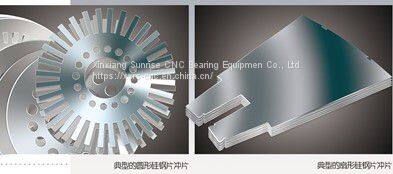

3M53130 Silicon steel sheet deburring machine

Machine application:

The machine adopts belt grinding method to remove the burr on silicon steel sheet, small residual amount, high efficiency, it is necessary for transformer and motor manufacturing plant, and also can be used for deburring and polishing work of punching plates in other industries.

Working accuracy :

Surface roughness Ra1.8~0.8(Sheet metal polishing)

Burr residue ≤0.003(without scratch the surface of silicon steel sheet)

Specifications and main technical parameters

Main technical parameters | 2M53100 | 2M53130 |

Max. Width of workpiece (mm) | 1000 | 1300 |

Min. Length of workpiece (mm) | 350 | 370 |

Thickness of workpiece (mm) | 0.2~1.5 | |

Size of abrasive belt (mm) | 1060*2000 | 1360*2200 |

Speed of abrasive belt (m/s) | 16 | 18 |

Workpiece feeding speed (m/min) | 6~40 (stepless) | |

Main motor power (kw) | 7.5 | |

Machine dimension (mm) | 2925*1750*1660 | 2925*2050*1760 |

Machine weight (kg) | 3000 | 3200 |

Structural features

1 ,The punching piece is passed between the pressure roller and the abrasive belt, and the deburring process can be completed at one time.

2 ,The back surface of the abrasive belt is provided with a precision elastic pad and a wear-resistant pad, which forms the pressure difference and the abrasion reducing effect, thereby ensuring the deburring precision (2M53130 is a precision slotted rubber roller).

3 The workpiece feeding use variable frequency speed regulation, and the apply speed range is large for punching piece passed.

4 The axial direction is equipped with the anti deviation device controlled by the photoelectric switch, so that when the belt is rotated at high speed, the belt can not be off tracking, and the abrasive belt grinding and abrasion are uniform, thereby improving the service life and the durability of the abrasive belt.

5 The machine is equipped with a large capacity vacuum cleaner, which can remove the burr and dust in time, so as to ensure the operator's physical health and the cleanliness of the machine.

6 Both ends of the machine punching piece inlet and outlet are equipped with hydraulic lifting platform, convenient operation, reduce the labor intensity of workers.

7 The machine can also add delivery, unloading and conveying device at the front and back end, can be composed by punching deburring automatic painting line.

Send Inquiry to This Supplier

You May Also Like

-

Bearing Ring Grinding MachineNegotiableMOQ: 1 Set

-

CNC Bearing Ring Grinding MachineNegotiableMOQ: 1 Set

-

Bearing Ring Grinding MachineNegotiableMOQ: 1 Set

-

Bearing Ring Grinding MachineNegotiableMOQ: 1 Set

-

Bearing Ring Grinding MachineNegotiableMOQ: 1 Set

-

Center Hole Grinding MachineNegotiableMOQ: 1 Set

-

Center Hole Grinding MachineNegotiableMOQ: 1 Set

-

CNC LatheUS$ 150000 - 200000MOQ: 1 Set

-

2M8470C Double Disk Grinding MachineNegotiableMOQ: 1 Set

-

2M84160 Double Disk Grinding MachineNegotiableMOQ: 1 Set