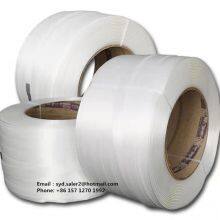

POLYESTER CORDED COMPOSITE STRAP PRODUCTION LINE From Shine East

Polyester strapping has many advantages over conventional, manually applied strapping products.

Would you like to eliminate transport damage to your cargo?

Are you looking for a safe and cost effective alternative to the steel strapping / metal banding you are currently using?

Polyester strapping solutions provide safe and cost effective ways to secure your cargo and prevent it from damage.

2. Straps Parameters

2. Light and soft , weight is only 20% of metal straps

3.Side is not sharpen , will not hurt commodities and workers .

4.Will not get rust and corrosion , will not change form .

5. Can use in a wide range of temperature and climate, can use in the condition of : from -40℃to 130℃

6. Can buffering impacting during commodities transportation

7. Can overlap and through space very conveniently without deforming

8.Convenient for using steel buckle using to package commodities .

* As strong as steel

* Safe for users & receivers

* Cost effective

* Does not damage your products

* Shock absorbent

* High retained tension

* High system strengths

* Printable with your company name & logo

* Light-weight & portable

* Chemical resistant

* Will not rust or rot

* Weather resistant

4. Machine’s General Information

Machine include

1 yarn frame

2 high efficiency heating over

3 high quality extruder

4 high precision yarn comb

5 composite die head

6 high precision mould

7 special design water tank

8 special design haul off

9 PLC controll winder

Send Inquiry to This Supplier

You May Also Like

-

Roller Perforation Sleeve Needle Segment for Micro Perforation Machine From Shine EastUS$ 95 - 150MOQ: 1 Unit

-

Jumbo Roll Punching Perforating Machine for Plastic Mulch Film Fabric PaperUS$ 18000 - 25000MOQ: 1 Set

-

PP Plastic Spiral Wrap Hydraulic Hose Protect Shrink Sleeve Making Machine From Shine EastUS$ 15000 - 19000MOQ: 1 Set

-

Shine East PVC Single Color Coil Mat Extrusion Machine Carpet Making Machine Floor Mat MachineUS$ 120000 - 120000MOQ: 1 Unit

-

Shine East Flexible Cord Bundler Wire Wrap Cable Management System Production Line for Office and PCUS$ 16500 - 18000MOQ: 1 Unit

-

Perforation Roller Pinned Perforation Roller for Woven Fabric LeatherUS$ 95 - 150MOQ: 1 Unit

-

High Speed Mulch Film Fabric Punching Machine Roll to Roll From Shine EastUS$ 25000 - 32000MOQ: 1 Set

-

Cord Composite Packing Belt Making Machine Polyester Yarn Composite Strap MachineUS$ 42000 - 120000MOQ: 1 Set

-

Composite Polyester Strap Extrusion LineUS$ 50,000 - 100,000MOQ: 1 Set

-

PET Fiber Composite Strip Production Line / Polyester Packing Strap Extrusion Machine / 2014 New Products in Plastic MachineryNegotiableMOQ: 1 Set