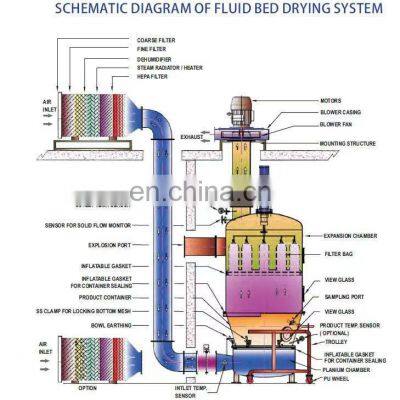

SenVen Batch Type Fluid Bed Dryer for Maggot Larvae and Salt Industrial

Send Inquiry to This Supplier

You May Also Like

-

WRH-100B Middle Temperature Stainless Steel Fruit And Vegetable DehydratorNegotiableMOQ: 1 Set

-

Small Drum Dryers Are Suitable for Peanut, Melon Seed, and Rapeseed Crops.US$ 4500MOQ: 1 Unit

-

Factory Final Manufacturer Instant Coffee Extraction Spray & Freeze Drying Machine Processing Plant Production LineNegotiableMOQ: 1

-

Freeze DryerUS$ 2000 - 2550MOQ: 1 Piece

-

HIROSS Factory Sale OEM Regenerative Desiccant Compressed Adsorption Air Dryer for CompressorNegotiableMOQ: 1

-

Drilling Mud Waste Vertica Cuttings Dyer SystemNegotiableMOQ: 1 Set

-

High Quality Dryer MachineUS$ 1,000 - 9,000MOQ: 1 Set

-

Rotary Dryer in Wood Pellet Production LineUS$ 19,200 - 20,000MOQ: 1 Set

-

China Industrial High Temperature Wood Rotary Drum Dryer for SaleUS$ 2,000 - 45,000MOQ: 1 Set

-

Good Quality Wood Sawdust Pellet Cooling MachineUS$ 2,500 - 4,800MOQ: 1 Piece