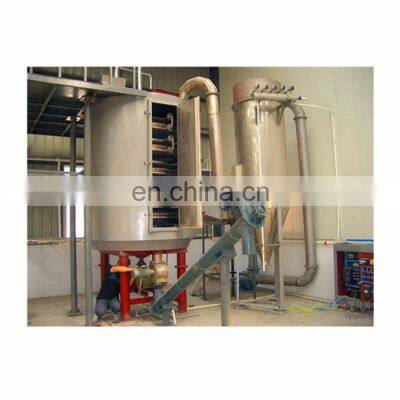

On Sale Advanced Technology PLG Plate Dryer Disc Dryer

PLG Series Continuous Disc Plate Dryer

DESCRIPTION

PLG Series Continuous disc dryer is a high efficiency conducting and continuous drying equipment. Its unique structure and operating principle determine that it has advantages of high heat efficiency, low energy consumption, small occupied area, simple configuration, easy operation and control as well as good operating environment and etc. It can be widely used in drying process in the fields of chemical, pharmaceuticals, agricultural, foodstuff, feed, and other industries.

There are three major types: normal pressure type, closed type, and vacuum type; and four major models: 1200, 1500, 2200 and 3000; and three kind of material grades, A (carbon steel), B (use stainless steel for material contacted area), and C (use stainless steel for material contacted area, steam pipes, main shaft and supports, and linings for cylinder body and top cover).The drying area of the dryer is 4 to 180m2. We have produced hundreds of models with auxiliary devices which are available to meet requirements of all customers.

WORKING PRINCIPLE

The wet material is fed continuously to the first drying layer on the top of the dryer. It will be turned and stirred by rakes when the rake arm rotates and drop down to the outer edge of the large drying plate along the exponential helical line. The material will be moved from the small drying plate to its outer edge and drop down to the outer edge of the large drying plate underneath. Both small and large drying plates are arranged alternately so the materials can go through the dryer continuously. The heat medium can be saturated steam, hot water or thermal oil. The heat will be led into hollow drying plates from one end and come out from the other end. The dried materials will drop from the last layer of the drying plate to the bottom of the dryer and then moved by rakes to the discharge outlet. The material moisture will be removed from the exhaust outlet on the top cover. For the vacuum-type plate dryer, the moisture will be sucked out by the vacuum pump on the top cover. The dried materials will be discharged from the bottom layer. The drying capability can be improved if the dryer equipped with supplementary devices such as finned heater, condenser for solvent retrieval, bag dust remover, return and mix mechanism, draft fan, and etc.

Applied in:

1.Chemical

2.Pharmaceutical

3.Foodstuff

4.Feed and fertilize

5.Agriculture and sideline products

Features:

1. Easy control , widely application

2. Simple operating

3. Low energy consumption

4. Good operation environment

5. Easy installation and small occupying area

FQA

Q: Where is your factory?

A: We are located in Changzhou City which about 150km away from Shanghai.

Q: What’s the quality control procedure?

A:We have an experienced technical team to support and provide solutions to meet the project requirements of our clients. We are certified with ISO9001 quality management system. We are following a strict quality control procedure to ensure the product quality.

Q: What is the warranty period?

A: 24 hours timely response of mail and phone calls. The warranty period for non-artificial damage is 1 year after delivery of goods.

Q: What is the payment term?

A: Our regular payment term is: 30% TT in advance, 70% TT before shipment.

Q: Does your price include freight?

A: Our usual price is based on FOB Shangha. We can provide CIF quote upon request.

Send Inquiry to This Supplier

You May Also Like

-

WRH-100B Middle Temperature Stainless Steel Fruit And Vegetable DehydratorNegotiableMOQ: 1 Set

-

Small Drum Dryers Are Suitable for Peanut, Melon Seed, and Rapeseed Crops.US$ 4500MOQ: 1 Unit

-

Factory Final Manufacturer Instant Coffee Extraction Spray & Freeze Drying Machine Processing Plant Production LineNegotiableMOQ: 1

-

Freeze DryerUS$ 2000 - 2550MOQ: 1 Piece

-

HIROSS Factory Sale OEM Regenerative Desiccant Compressed Adsorption Air Dryer for CompressorNegotiableMOQ: 1

-

Drilling Mud Waste Vertica Cuttings Dyer SystemNegotiableMOQ: 1 Set

-

High Quality Dryer MachineUS$ 1,000 - 9,000MOQ: 1 Set

-

Rotary Dryer in Wood Pellet Production LineUS$ 19,200 - 20,000MOQ: 1 Set

-

China Industrial High Temperature Wood Rotary Drum Dryer for SaleUS$ 2,000 - 45,000MOQ: 1 Set

-

Good Quality Wood Sawdust Pellet Cooling MachineUS$ 2,500 - 4,800MOQ: 1 Piece