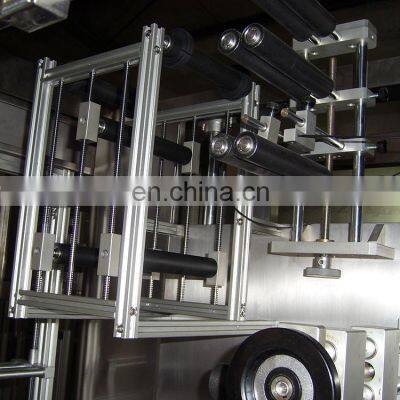

Automatic Heat Shrink Bottle Labeling Machine 60-120mm Bottle Diameter

Product Name | SED-100RTB-K Sleeve Labeling Machine |

Capacity | 3000-6000 bottles/hour |

Bottle diameter | 60mm~120mm, special size can be customized |

Bottle height | 30 mm -320 mm, special height can be customized |

Label length | 30mm~250mm |

Label thickness | 0.027mm~0.13mm |

Label material | PVC, PET, OPS |

Voltage | AC380V, 50/60HZ, 3-phase |

Power | 3KW |

Dimensions | 2100*850*2000mm |

Total weight | 900 kg |

Send Inquiry to This Supplier

You May Also Like

-

UV Crystal Label DTF Machine for Glass, Metal, Plastic, Wood, Cloth, Ceramics Etc.NegotiableMOQ: 1 Set

-

Handheld Marking MachineUS$ 95 - 100MOQ: 5 Pieces

-

Industrial Ice Pop Fold Label MachineNegotiableMOQ: 1

-

TOWA APN-60 Labeler,RFID Tag Label ApplicatorUS$ 140.16 - 166.67MOQ: 50 Pieces

-

Indoor Touch Screen LCD Self Service Payment Kiosk With 58mm Kiosk PrinterNegotiableMOQ: 1 Piece

-

Booster Brand Label Attaching MachineUS$ 1 - 999MOQ: 1 Set

-

18 Stainless Steel Sleeve and Shrink Labeling Machine +86 15136240765US$ 2,000 - 5,000MOQ: 1 Set

-

Manual Sticker Labeling MachineUS$ 5,000 - 9,000MOQ: 1 Set

-

Made In China Bottle Label Peeling Machine With DiscountUS$ 1,999 - 4,999MOQ: 1 Set

-

Hot High-tech Semi-automatic Pneumatic Flat Bottle Labeling MachineUS$ 3,000 - 15,000MOQ: 1 Set