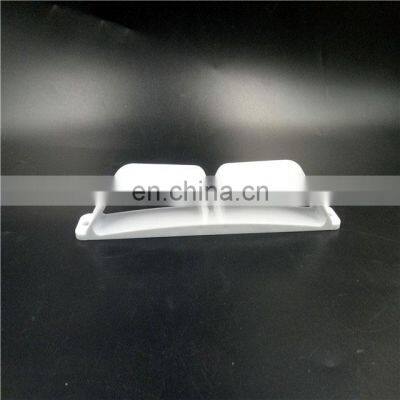

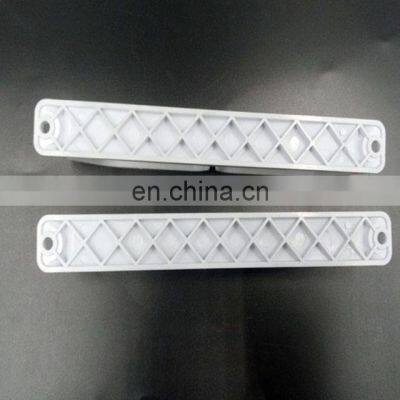

Superfine Abrasion Performance Tooling Cost 3d 2d Pdf Injection Molding Zetarmold

Product Name | Easy tinting Insulating and 3d printed rapid tools |

Material | ABS/PP/PC/HDPE/HIPS/HDPS/PVS/PMMA/PA/NYLON/POM |

Function | Rapid prototyping; |

Package | 1-Wrapped with plastic bag or pearl-cotton protective packing material. 2-Put 5 layers standard export cartons with rigid protective layer. 3-Use glue tape to seal cartons. 4-Loading on pallet with protective rigid corners 5-Loading container for sea shipping. Remark:if need DHL,FEDEX or UPS and so on express then no pallet needed |

Product performance description

Cojoy delivers a wide variety of injection molded, CNC machined, and 3D Printed parts in under fifteen (15) business days.

Online quotes available in less than 24 hours.

Our Services & Strength

3-Use glue tape to seal cartons.

4-Loading on pallet with protective rigid corners

5-Loading container for sea shipping.

Remark:if need DHL,FEDEX or UPS and so on express then no pallet needed

A1: Materials selection depends on the application of your design and the environment in which it will function.

We will be happy to discuss the alternatives and suggest the best material.

Q2: What type of mould tool do I need?

A2: Mould tools can be either single cavity (one part at a time) or multi-cavity (2,4, 8 or 16 parts at a time).

Single cavity tools are generally used for small quantities, up to 10,000 parts per year whereas multi-cavity tools are for larger

quantities.We can look at your projected annual requirements and recommend which would be best for you.

Q3. What is the working life of the mould?

A3: It depends on the parts we made. Besides, we will maintain or replace the mould be ourselves.

Q4:Can you guide me to do the design works.

A4:Yes,we have more than 5 engineers,they can understand English and even speak English,so if you need design help,they can work

together with you to sort out without problem

Q5:Do you have any guidebook which can send to us for design work helping

A5:Yes,we would be glad to.Please contact us by email :inquiry @ and make your point clear,then our team will

help you.

Send Inquiry to This Supplier

You May Also Like

-

High Recovery Gold Washing Carpet Mining Alluvial Gold Moss Mat Grass Carpet Gold Mining CarpetNegotiableMOQ: 10 Rolls

-

LG PC/ABS Lupoy GN-5001RF Polycarbonate + ABS Resin Plastic Raw MaterialUS$ 1.5 - 2MOQ: 25 Kilograms

-

Bottle Sealing Lock Buckle Plastic Rings for Decorative Sealing BOLIUS$ 0.1 - 0.2MOQ: 10 Pieces

-

ZYTEL(R) ST801 NC010 Engineering Thermoplastic Resin With Superior Chemical ResistanceUS$ 5.6 - 6.6MOQ: 25 Kilograms

-

High-BARRIER Plastic Wear-Resistant and Chemically Resistant for Various Projects in POK M330A PolyketoneUS$ 3.72 - 3.88MOQ: 25 Kilograms

-

Hot Selling 5500m2/m3 MBBR Bio Filter Floating Media Biochip 30 for Ras AquacultureUS$ 150 - 480MOQ: 1 Cubic Meter

-

Pier Buoy Floating Box on Water Pontoon BridgeUS$ 12 - 15MOQ: 50 Pieces

-

16mm 19mm 25mm 38.1mm Round Square Tube End Leg Tip Plastic Pipe PlugNegotiableMOQ: 100 Pieces

-

Portable Pop up Privacy Shower Tent Spacious Changing Room for Camping Hiking Beach Toilet Shower BathroomUS$ 24.00MOQ: 1 Set

-

Shenzhen Runpeng Custom Injection ABS PP Plastic PartsNegotiableMOQ: 1