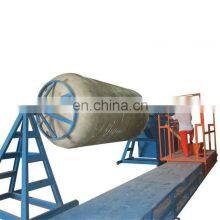

Automatic GRP FRP Horizontal Tank Production Line Fiberglass Tank Winding Machine

Model number | Maxi diameter (mm) | Maxi length (mm) | Rang of idameter (mm) | Total power (kw) | Maxi width of roving sheet (mm) | Productivity(kg/h) |

JFW-1500 | 1500 | 6000 | 25~1500 | 5.5 | 150 | 450 |

JFW-2500 | 2500 | 12000 | 25~2500 | 7.5 | 150 | 500 |

FW-10000 | 10000 | 12000 | 4000~10000 | 14.6 | 168 | 550 |

FW-15000 | 15000 | 12000 | 4000~15000 | 18.6 | 168 | 550 |

VFW-25000 | 25000 | 12000 | 4000~25000 | 500 |

Major products:

FRP vessel and chemical equipment in sets; FRP pipes, FRP panel water tank, FRP grating, FRP molded & pultruded products, other fiberglass products.

Electrolytic cell, S/F, F/F oil storage tank, FRP duce pipe FRP absorber, FRP cooling tower, etc....

Hengshui Jiubo Composites Co., Ltd. not only have manufacture ability, but also has design ability of material, structure and products, our company can provide customers with technical advice, supply of goods and material, transportation, installation supervision etc service.

Send Inquiry to This Supplier

You May Also Like

-

Weighing Booth/dispensing Booth/vertical Flow BoothNegotiableMOQ: 1 Set

-

Automatic Brick Making Machine Equipment Cement Brick Making Machinery From China Construction Compressed Brick Making MachineUS$ 399 - 1142MOQ: 1 Set

-

Safe Dehumidifier Greenhouse Or CellarUS$ 1 - 10000MOQ: 1 Piece

-

Tu0 C1011 C10100 C110 Pure Copper Bar Customized Industrial Seamless Good QualityNegotiableMOQ: 1 Ton

-

Perkins Engine 404-22 Original Brand New 4-cylinder GN71039 24.3KW/1800CNegotiableMOQ: 1 Piece

-

Metallographic Sample Thin Section Equipment/Specimen Cutting MachineUS$ 22183.35 - 23093.07MOQ: 1 Set

-

Waste Car Radiator Crushing Separating Machine Scrap AC Radiator Recycle MachineUS$ 37865MOQ: 1 Set

-

Genyond Brand Ballpoint Pen Refill Tube Making MachineNegotiableMOQ: 1

-

Belt ChainNegotiableMOQ: 1 Set

-

15m Motorcycle Production Assembly Line Cheap MarketingNegotiableMOQ: 1